Multi-module automatic dismounting and mounting lifting mechanism and lifting method

A lifting mechanism and automatic disassembly technology, which is applied in the direction of lifting devices, conveyors, mechanical conveyors, etc., can solve the problems that the lifting mechanism cannot realize automatic disassembly and assembly, and achieve the effect of compact structure, reducing shaking, and overcoming shaking at high places

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0039] The present invention will be further described in detail below with reference to the drawings and specific embodiments.

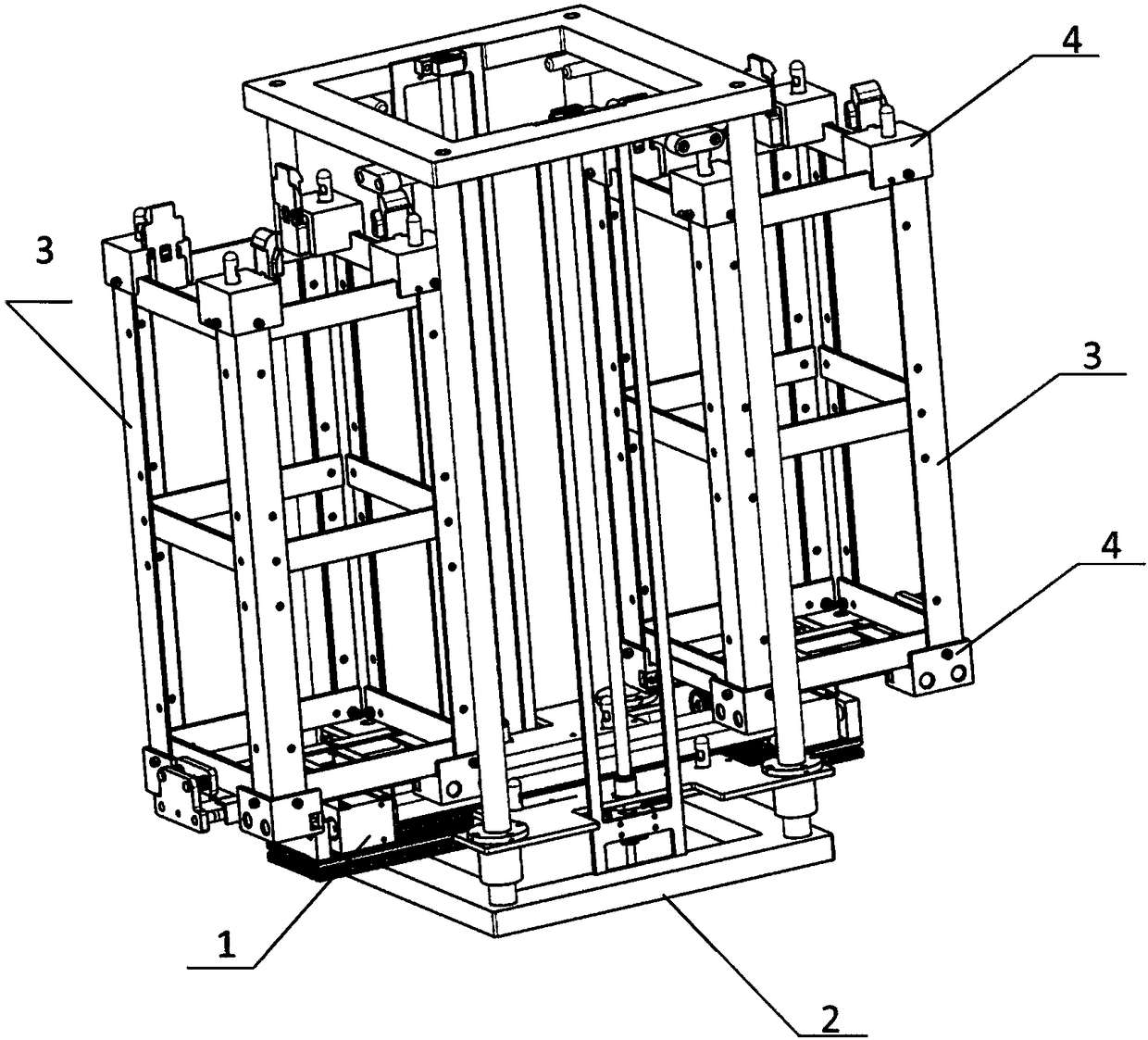

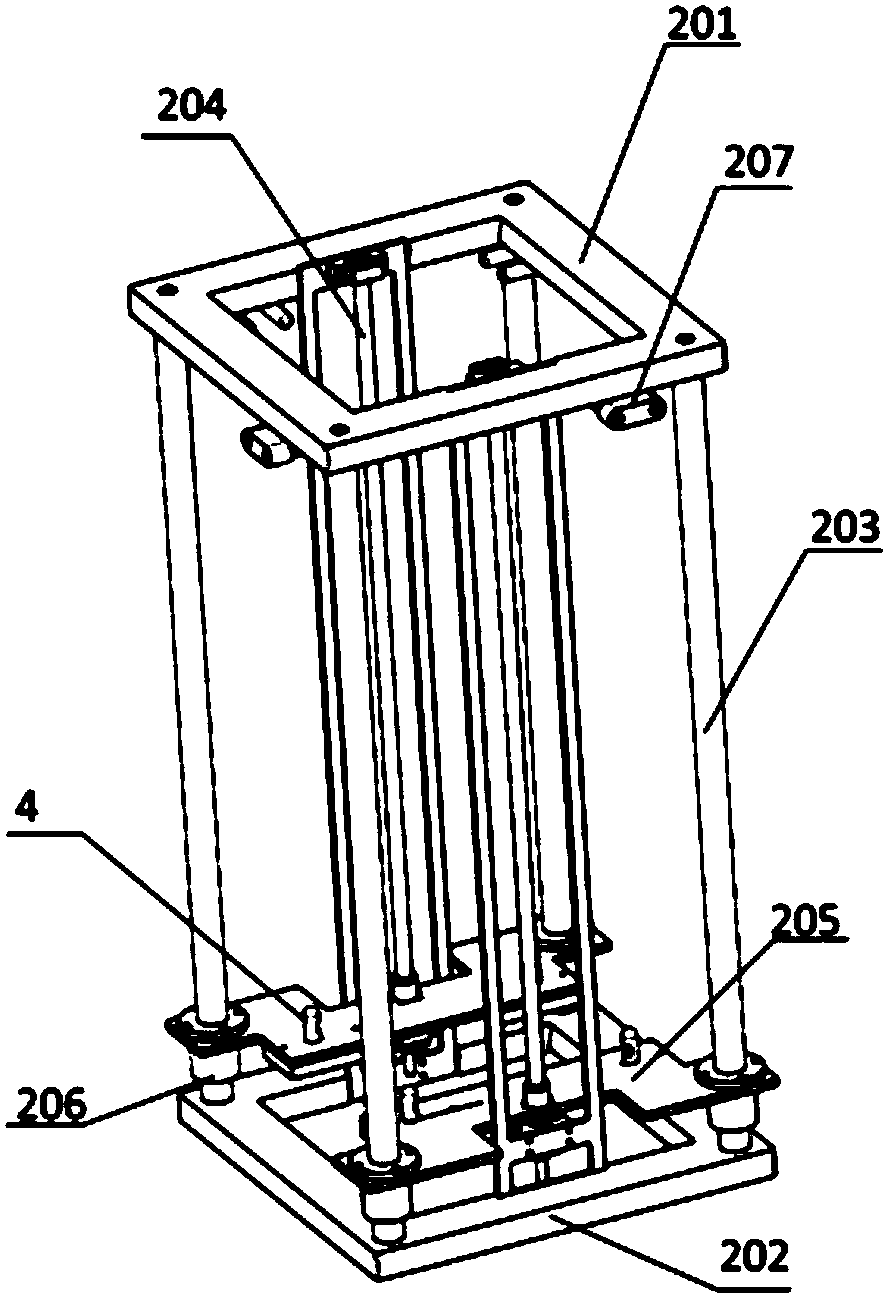

[0040] reference figure 1 , A multi-module automatic disassembly and assembly lifting mechanism of the present invention includes an automatic translation mechanism 1, an automatic lifting mechanism 2 and a plurality of modules 3.

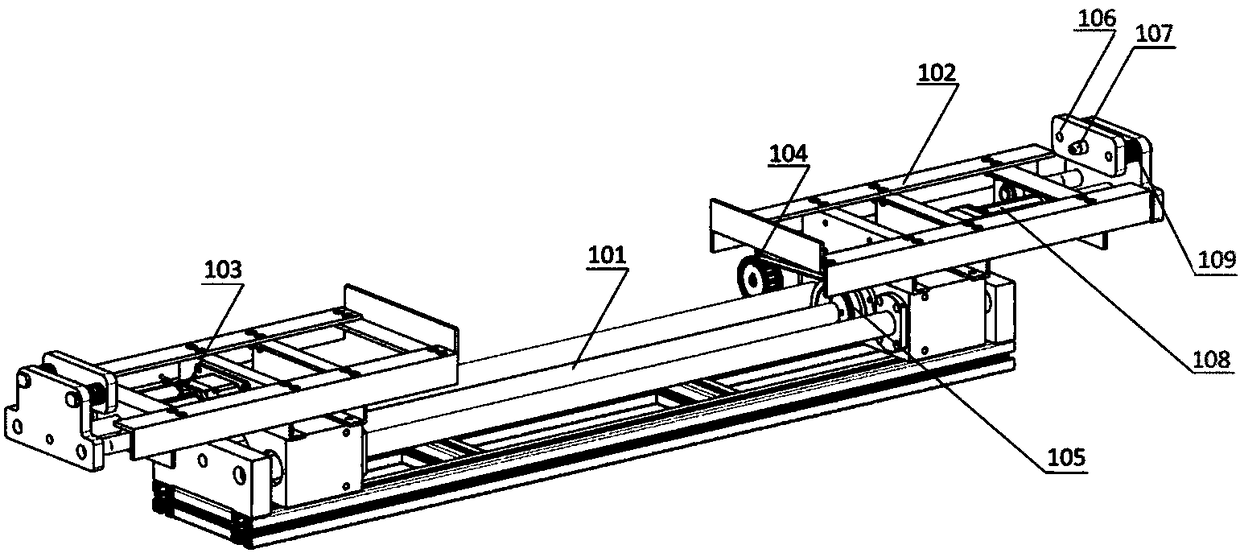

[0041] reference figure 2 The automatic translation mechanism 1 includes an automatic horizontal movement device and a tray 102. The tray 102 is installed on the automatic horizontal movement device. The automatic horizontal movement device can realize the automatic horizontal movement of the tray 102. The tray 102 is used to place the module 3 through the tray 102. The horizontal movement of the module 3 can be transported to the preset station, so that the module 3 can be connected with the automatic lifting mechanism 2.

[0042] The automatic horizontal movement device is a horizontally arranged ball screw mechanism, including

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap