Frost heave prevention pile and construction method

A construction method and anti-frost heave technology, which can be used in infrastructure engineering, protection devices, buildings, etc., can solve the problems of high engineering cost, large length and length of reinforcement, and achieve the effects of low cost, reduced labor cost, and high speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0015] Example 1:

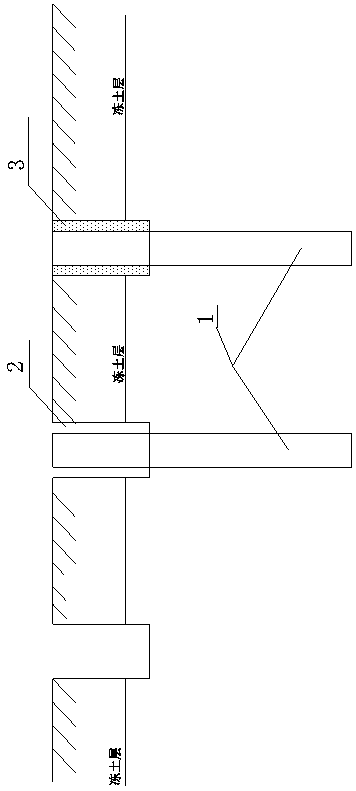

[0016] An anti-frost heave pile, which is composed of a prefabricated pile. The upper pile circumference of the prefabricated pile is provided with an anti-frost heave ring-shaped layer, and the anti-frost heave ring layer is composed of an anti-frost heave material.

Example Embodiment

[0017] Example 2:

[0018] According to the anti-frost heave pile described in embodiment 1, the pile body of the prefabricated pile is coated with asphalt or covered with linoleum, the anti-frost heave layer is backfilled sand, and the top of the anti-frost heave layer has a layer of waterproof cohesive soil. The precast piles mentioned are concrete precast piles or steel piles.

Example Embodiment

[0019] Example 3:

[0020] The above-mentioned construction method of anti-freeze heave piles, after leveling the working surface, use a drill to drill the anti-freeze hole 1, and then implant the precast pile 2 in the anti-freeze hole. The depth of the anti-freeze hole is greater than the depth of the frozen soil layer. The remaining space is filled.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap