Method for improving indoor temperature compressing plasticity of amorphous alloy

An amorphous alloy, room temperature technology, applied in the field of metal material preparation, can solve problems such as material failure and fracture, and achieve the effects of adjustable performance, easy availability of materials, and simple mold structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

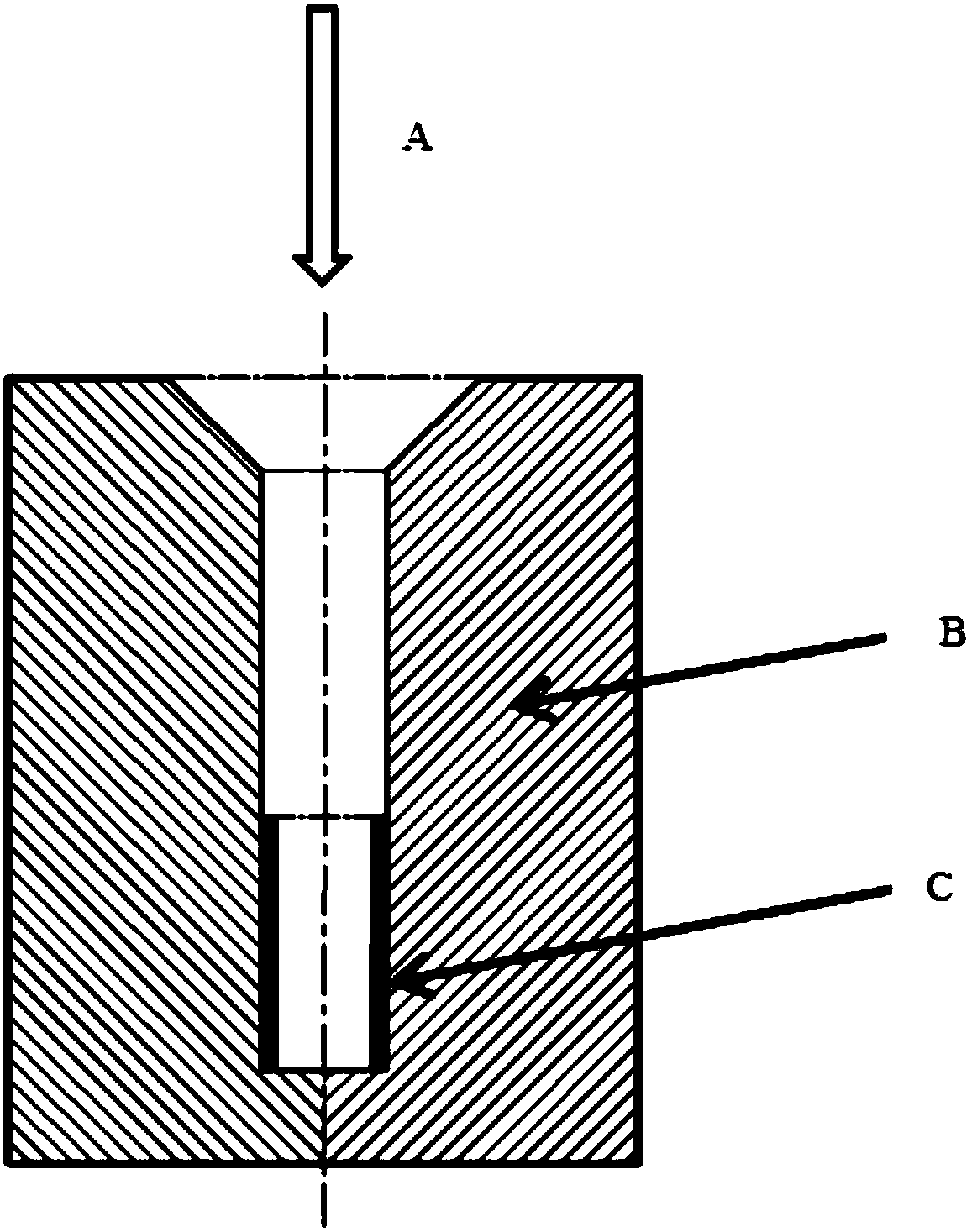

[0030] Specific implementation mode 1: This implementation mode is a method for improving the room temperature compression plasticity of amorphous alloys, specifically according to the following steps:

[0031] 1. Put the 45# steel pipe into the copper mold, and the outer diameter of the 45# steel pipe is the same as the diameter of the inner hole of the copper mold;

[0032] Two, the alloy melt is fully smelted, then filled into the copper mold of step 1 assembling 45# steel pipe, cooling, taking the material, obtaining a composite material that is a steel pipe on the outside and an amorphous alloy on the inside, and completes the process of raising the room temperature of the amorphous alloy methods of compressive plasticity.

specific Embodiment approach 2

[0033] Embodiment 2: This embodiment differs from Embodiment 1 in that: the inner round hole of the copper mold described in step 1 has a bottomed structure, and the diameter of the round hole is 4 mm to 20 mm. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0034] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the inner circular hole of the copper mold described in step 1 has a bottomed structure, and the diameter of the circular hole is 5 mm. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap