Highly-conductive carbon material and low-temperature preparation method thereof

A technology of high conductivity and carbon materials, applied in the preparation/purification of carbon, manufacturing of hybrid/electric double layer capacitors, circuits, etc., to achieve the effects of wide application range, good stability and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Example 1. Preparation of highly conductive carbon material at low temperature

[0024] (1) 10g of compound 1 is added to a 100ml two-necked bottle;

[0025] (2) Gradually heat to 150°C under the protection of nitrogen;

[0026] (3) When the temperature reaches the target temperature, react for 6 hours under these conditions to obtain a black solid powder, which is a highly conductive carbon material.

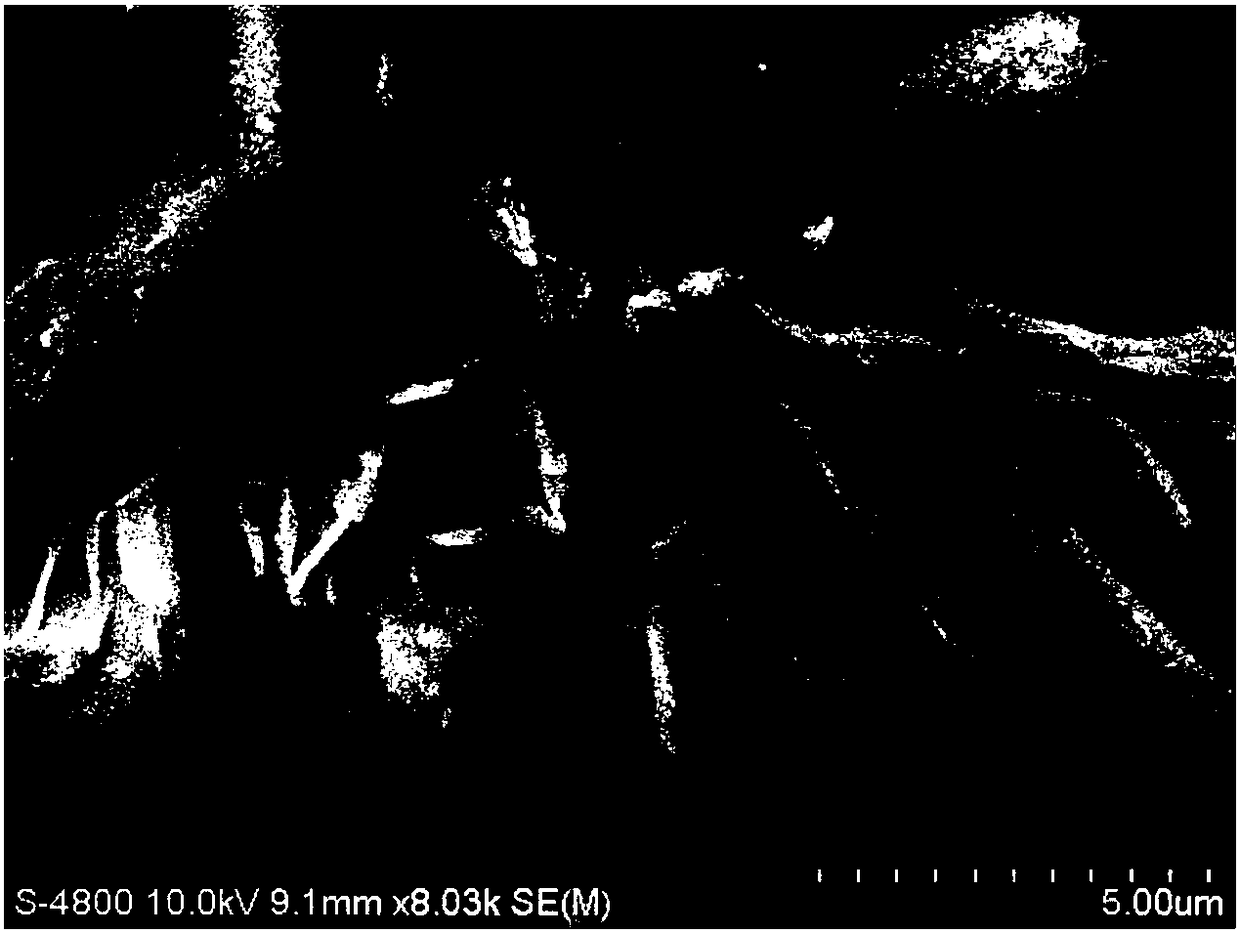

[0027] The scanning electron micrograph of the carbon material prepared by the invention is as figure 1 Shown by figure 1 It can be seen that the prepared carbon material has a band-like structure, and its conductivity is 10 S / m.

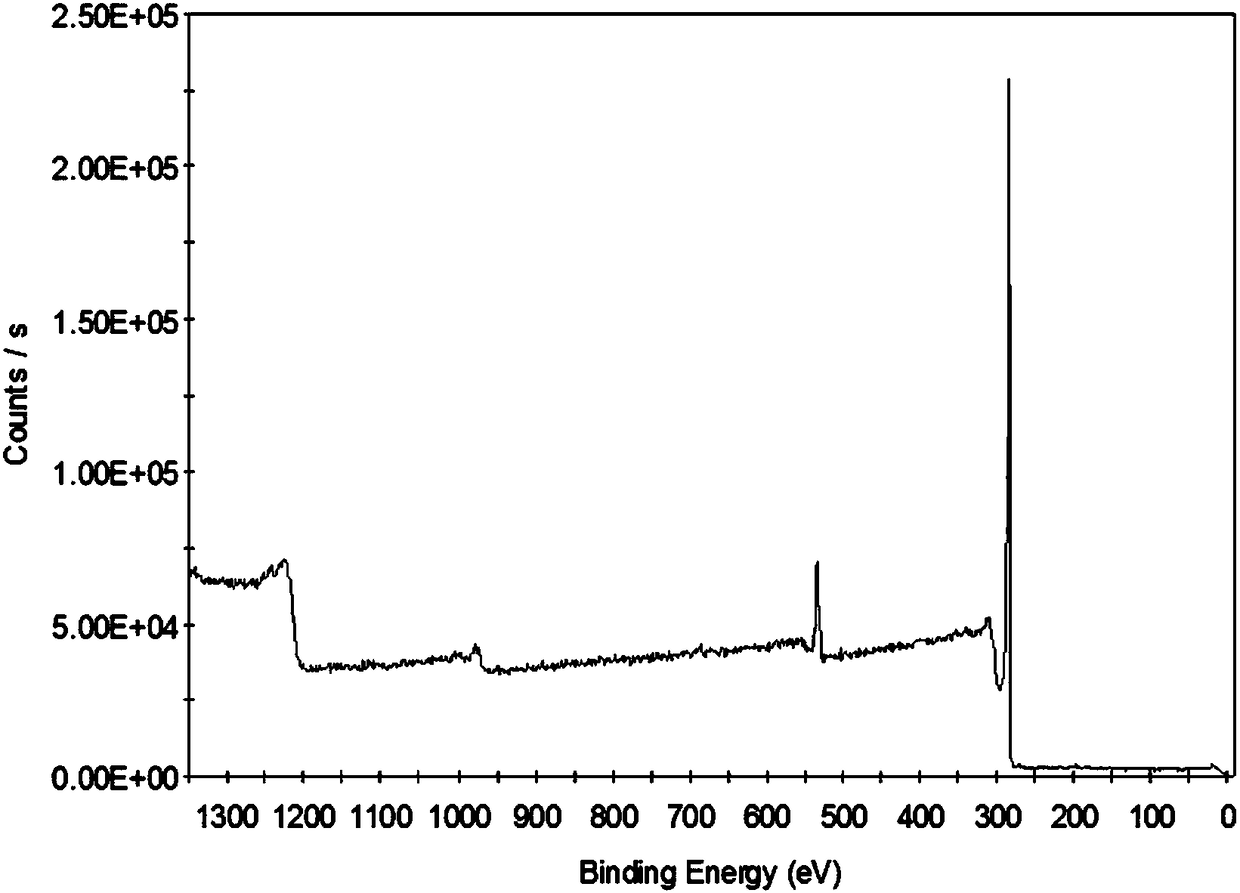

[0028] The X-ray photoelectron spectroscopy (XPS) spectrogram of the carbon material prepared by the present invention is as follows figure 2 As shown, the carbon content is 97%.

Embodiment 2

[0029] Example 2. Low-temperature preparation of highly conductive carbon materials

[0030] (1) Heat a 500ml reactor to 300°C in air;

[0031] (2) Gradually add 20g of compound 6 to the above 500ml reactor;

[0032] (3) React for 8 hours under these conditions to obtain a black solid powder, which is a highly conductive carbon material.

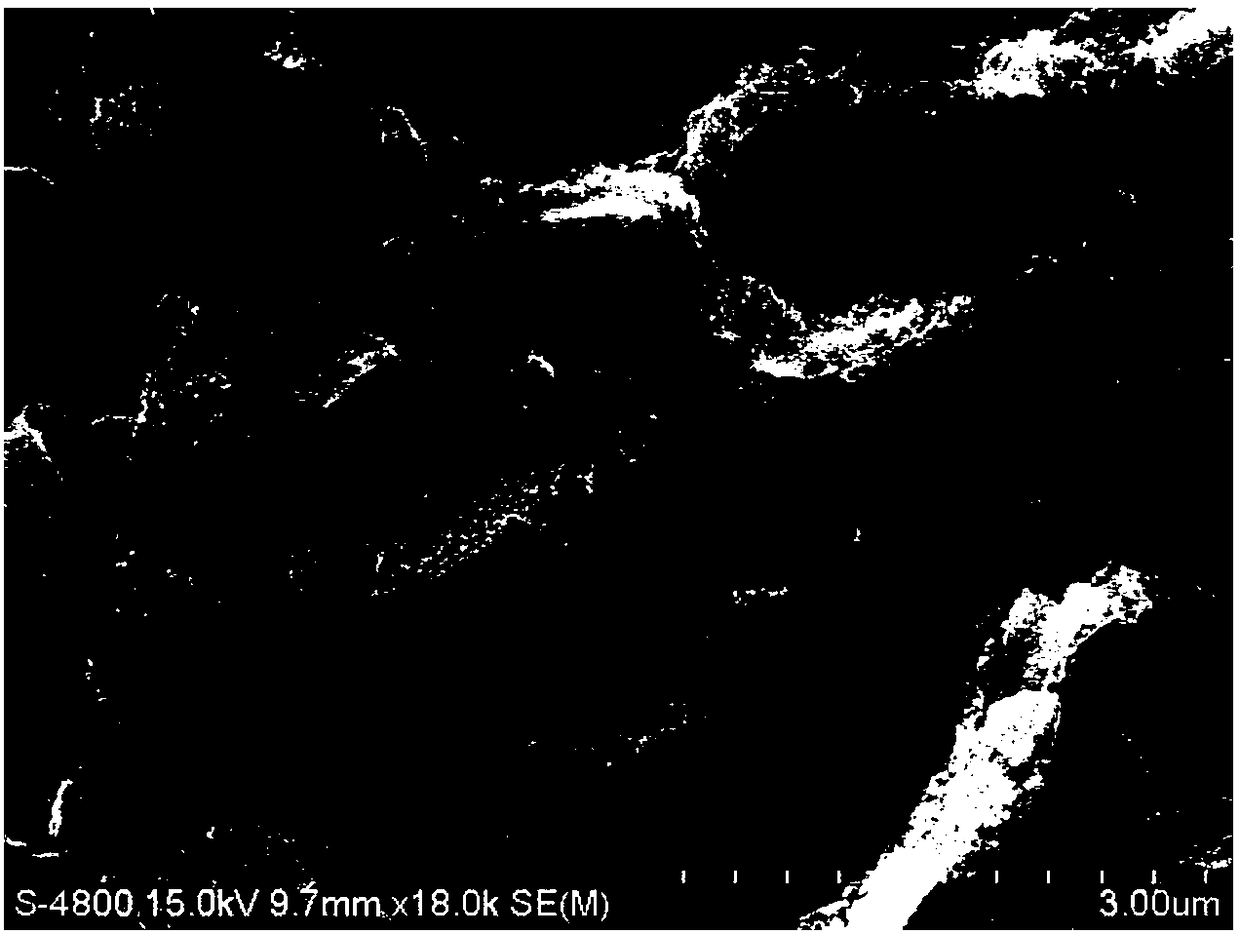

[0033] The scanning electron micrograph of the carbon material prepared by the present invention is as image 3 Shown by image 3 It can be seen that the prepared carbon material has a particulate structure with a conductivity of 14 S / m.

Embodiment 3

[0034] Example 3. Low-temperature preparation of highly conductive carbon materials

[0035] (1) First, compound 4 and compound 11 are uniformly mixed according to a mass ratio (1:3) to obtain a mixture with a mass of 100 g;

[0036] (2) Heat a 1000ml reaction flask to 200°C under oxygen protection;

[0037] (3) Gradually add the mixture obtained in step (1) to the reaction flask of step (2), and react for 6 hours under these conditions, which is a highly conductive carbon material, and the conductivity of the porous structure reaches 28 S / m.

[0038] The scanning electron micrograph of the carbon material prepared by the invention is as Figure 4 Shown by Figure 4 It can be seen that the prepared carbon material has a porous structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap