Combing and dedusting mechanism for woolen materials

A carding and feeding technology, used in deburring devices, cleaning machines, textiles and paper making, etc., can solve the problems of poor dust removal quality, low dust removal efficiency, secondary pollution of wool textiles, etc. Reasonable effect of structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to further describe the present invention, a specific implementation of a wool combing and dust removal mechanism will be further described below in conjunction with the accompanying drawings. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

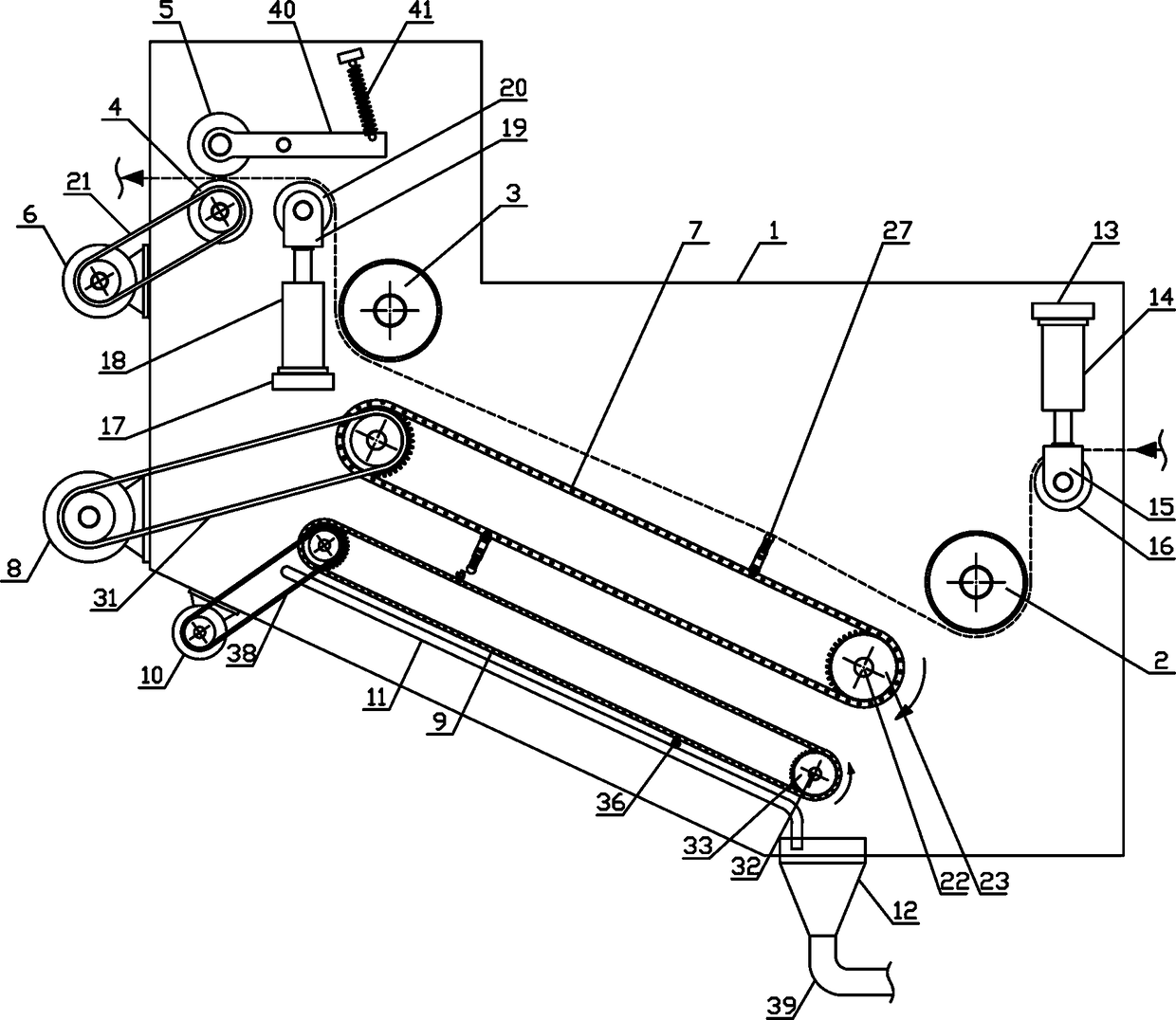

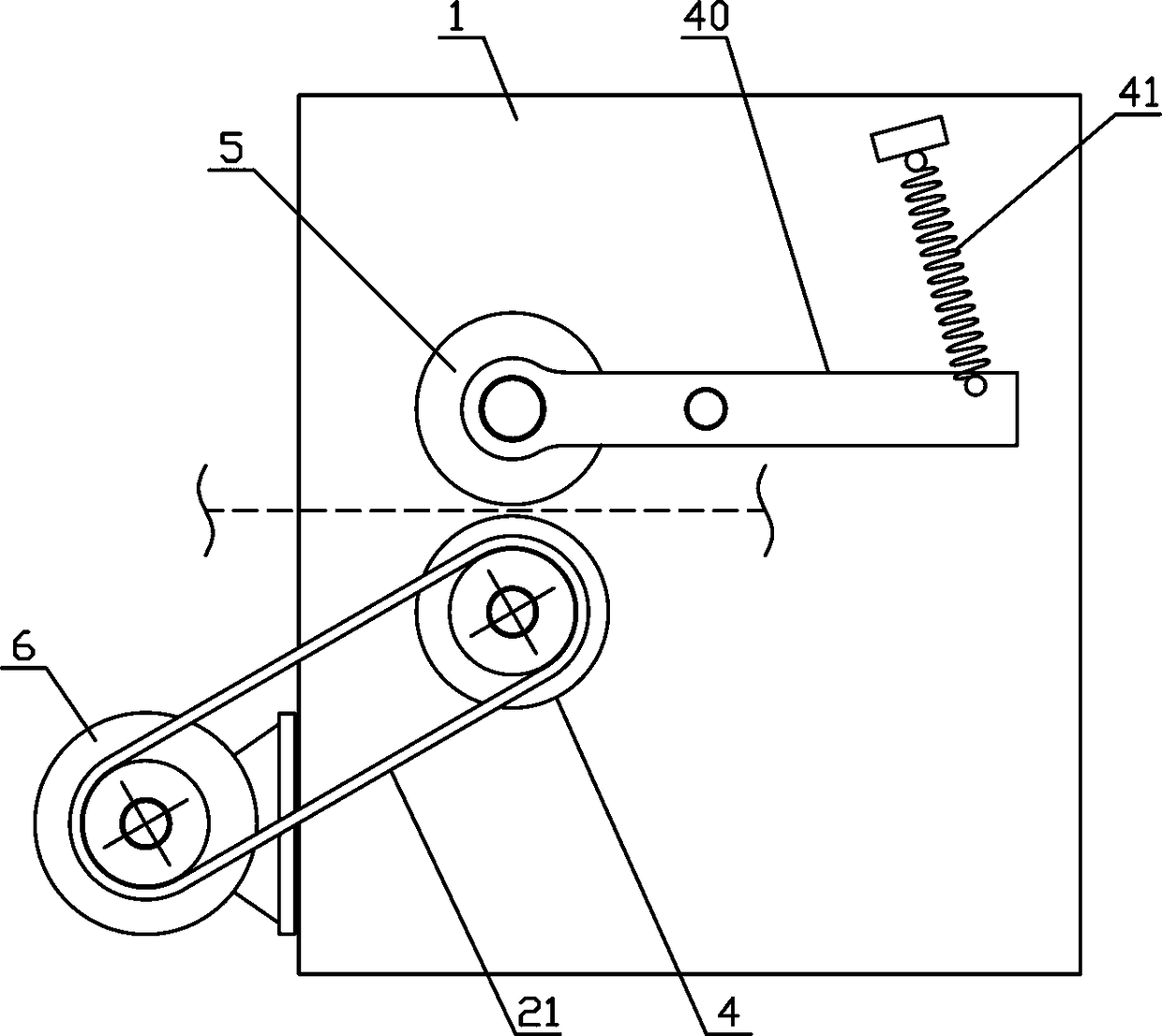

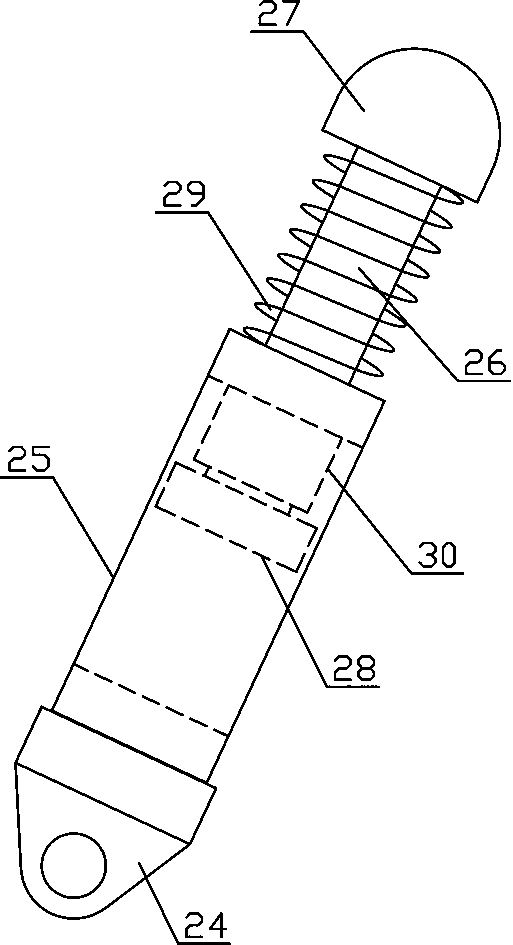

[0015] Such as figure 1 As shown, a woolen material carding dust removal mechanism of the present invention comprises a fixed support 1, a front carding roller 2, a rear carding roller 3, a pulling roller 4, a pressing roller 5, a pulling motor 6, a dust removal chain 7, a dust removal Motor 8, dust sweeping chain 9, dust sweeping motor 10, dust retaining slant plate 11 and dust collection hopper 12, front combing roller 2 is horizontally connected to one side below fixed support 1, and front combing roller 2 one side upper ends are horizontally fixedly provided with Feeding connecting plate 13, feeding cylinder 14 is fixed vertically downwar

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap