Thermal compressing machine with movable thermal compressing head

A hot press head and mobile technology, which is applied in the field of hot press machines with movable hot press head, can solve the problems of inconvenient operation, increased labor intensity of staff, and reduced work efficiency, so as to achieve improved work efficiency, novel structure, and guaranteed The effect of hot pressing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the following specific embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

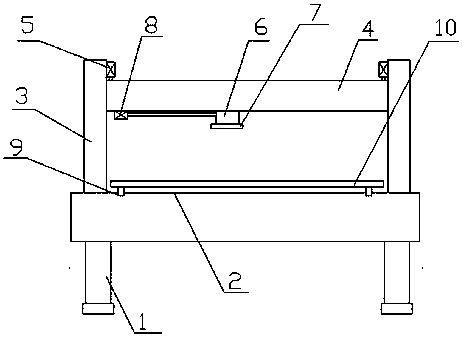

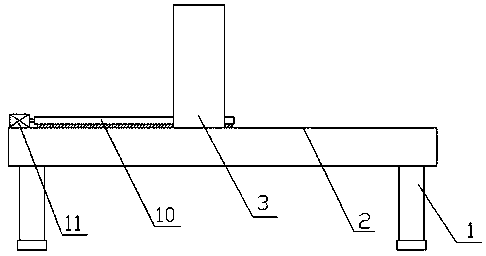

[0020] As shown in the figure, a heat press with a movable hot head according to the present invention includes a frame 1 and a controller, the upper end of the frame 1 is a workbench 2, and two Both sides are fixedly provided with column 3, and vertical chute 1 is all provided with on the opposite side of described two columns 3, is provided with pressing plate 4 between described two columns 3, and described pressing plate 4 and driving device 1 5 Transmission connection, both ends of the pressure plate 4 are slidingly arranged in the first chute, the lower end surface of the pressure plate 4 is provided with a sliding guide rail, and a thermal pressure head 6 is slidab

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap