Preparation method of Y0.95F3:0.05Ce<3+> nano particle fluorophor

A technology of nanoparticles and phosphors, which is applied in the direction of chemical instruments and methods, luminescent materials, etc., can solve the problems of unsatisfactory luminous intensity of products, insufficient closeness of onlooker aggregation, and uneven dispersion, and achieve stable luminescence, low price, and dispersed uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0025] Example 1: One Y 0.95 F 3 :0.05Ce 3+ Preparation of Nanoparticle Phosphor

[0026] Accurately weigh 47.8825gY(NO 3 ) 3 .6H 2 O is dissolved and diluted in a 500ml volumetric flask to make 0.25mol / L Y(NO 3 ) 3 The solution is reserved. Add 5.4265g Ce(NO 3 ) 3 .6H 2 O is dissolved and diluted in a 50ml volumetric flask to form 0.25mol / L Ce(NO 3 ) 3 The solution is reserved. Use a pipette to accurately pipette 19ml 0.25mol / L Y(NO 3 ) 3 , 1000μl 0.25mol / L Ce(NO 3 ) 3 , Plus 3.4848g (control RE 3+ :SDBS=1:2, where RE 3+ Is the trivalent rare earth ion Ce 3+ And Y 3+ Sum) Sodium dodecylbenzene sulfonate (SDBS) in a 100ml small glue beaker, then add a stir bar, temperature 23℃, magnetic stirrer, set stirring speed 100r / min, stir 52min, then add 2.800g (2314μl) 1-butyl-3-methylimidazole tetrafluoroborate, covered with plastic wrap (airtight), stirred for 4h at 100r / min. The mixture was transferred to a 100ml polytetrafluoroethylene reactor. The reaction kettle was place

Example Embodiment

[0028] Example 2: The product prepared in Example 1 was tested as follows

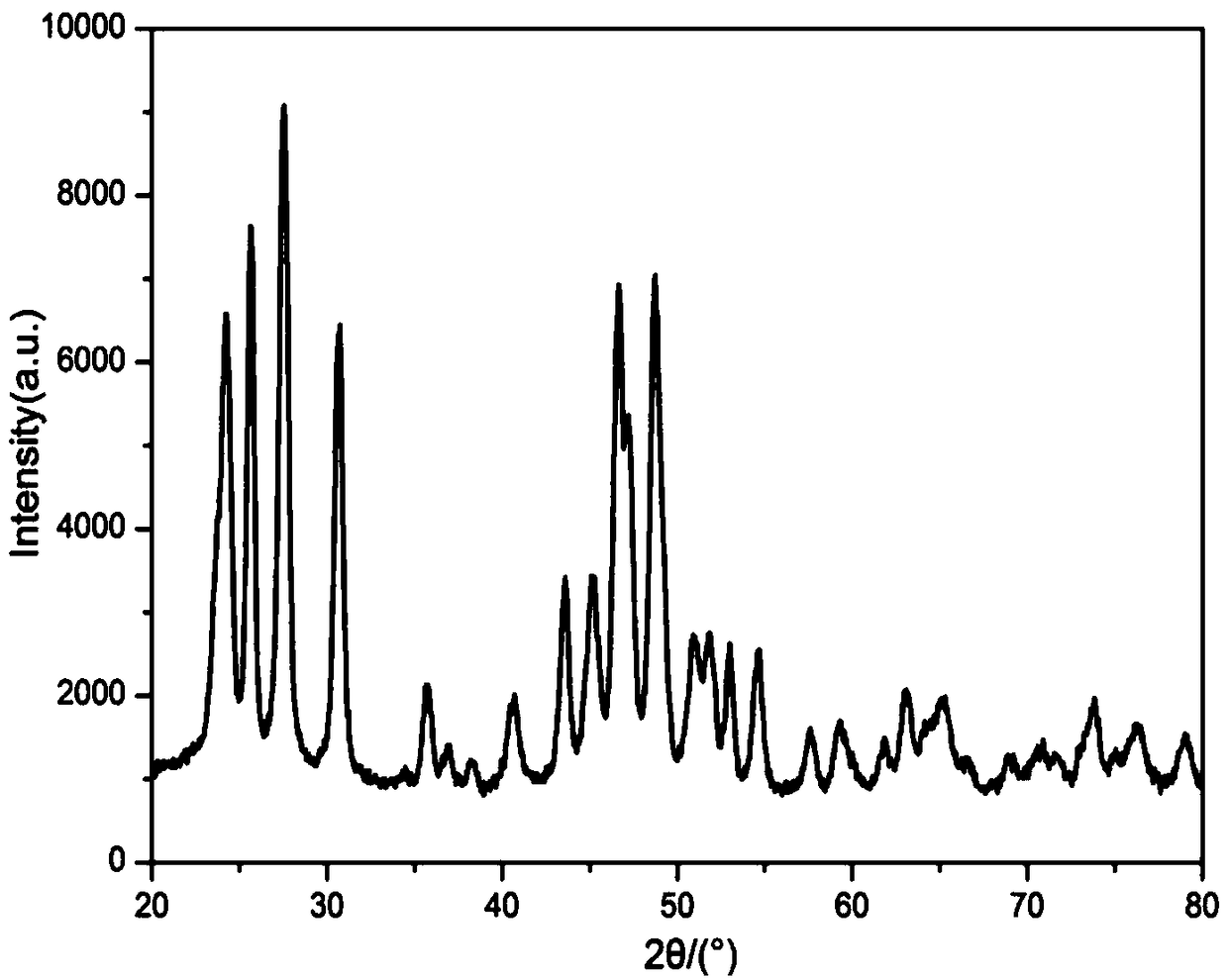

[0029] The product obtained in Example 1 was subjected to XRD test:

[0030] The radiation source is Cu Ba, the wavelength is 1.54060m, the scanning angle is 20°~80°, the voltage is 30kV, the current is 20mA, and the scanning speed is 2.4° / min. The XRD diffraction pattern of X-ray nanoparticles is as follows figure 1 Shown. It can be seen from the figure that the XRD diffraction angle 2θ is 24.208±0.2°, 25.610±0.2°, 27.532±0.2°, 30.701±0.2°, 35.688±0.2°, 40.675±0.2°, 43.584±0.2°, 45.143±0.2°, 46.649±0.2°, 47.221±0.2°, 48.675±0.2°, 50.909±0.2°, 51.844±0.2°, 52.987±0.2°, 54.649±0.2°, etc., there are engagement peaks.

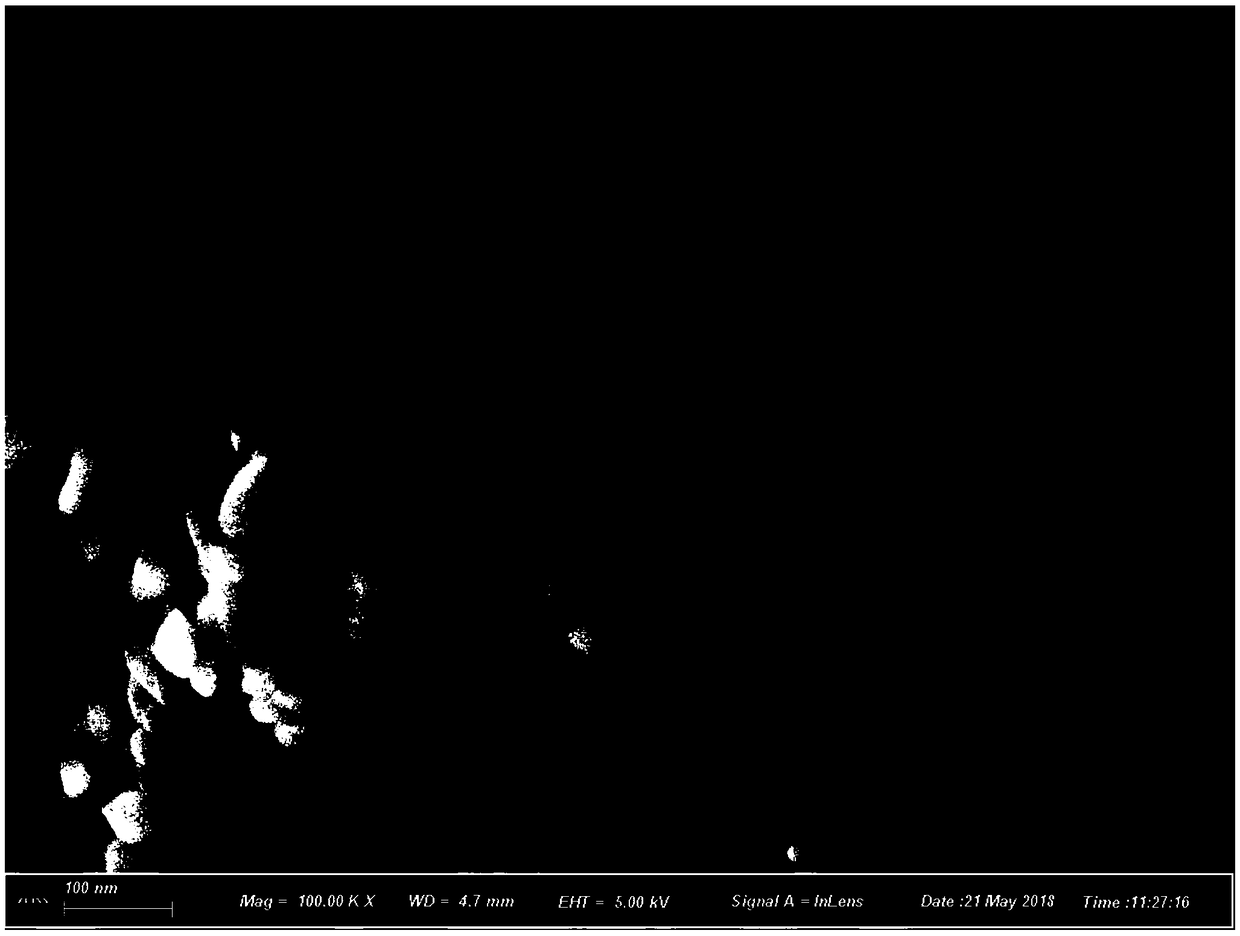

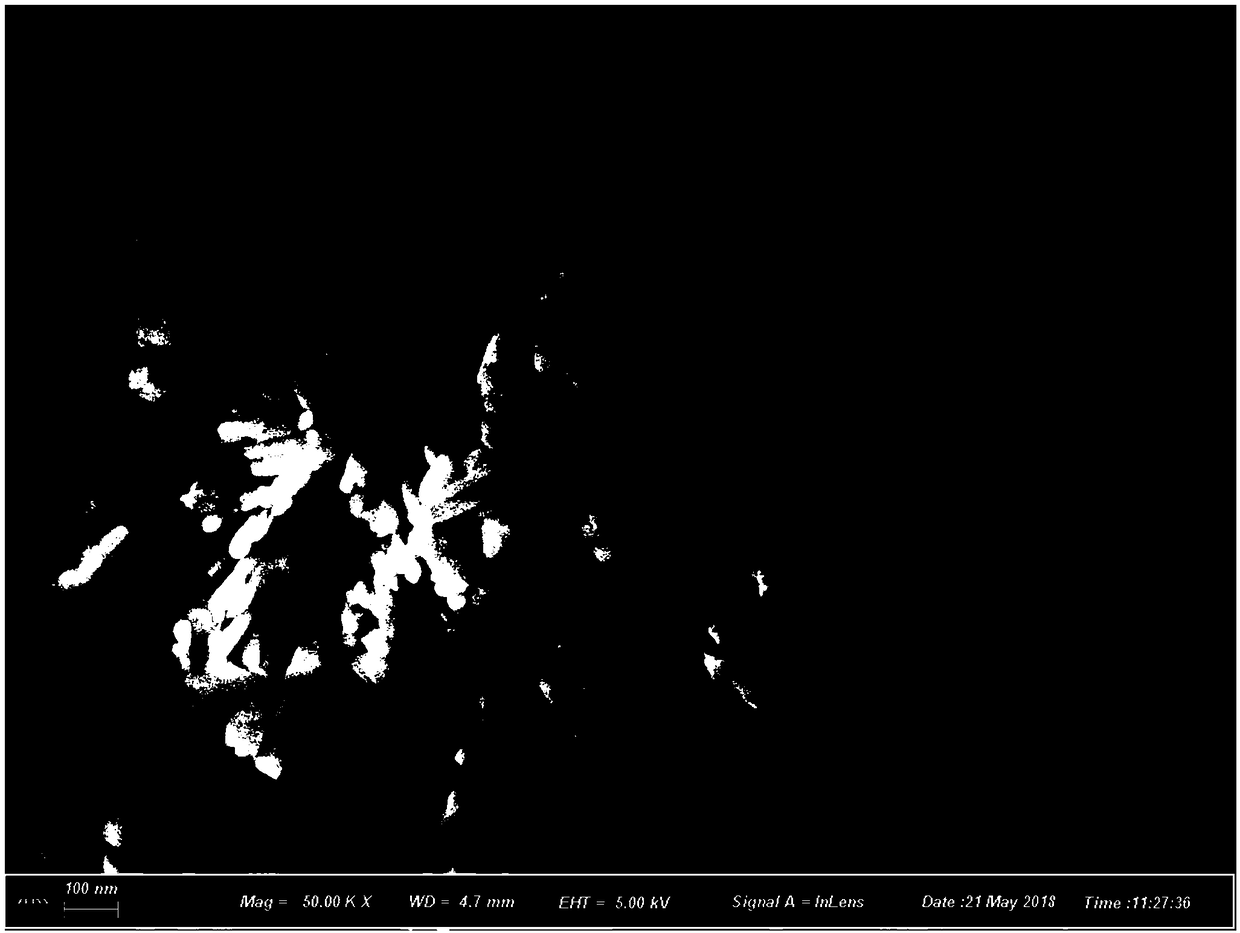

[0031] The product prepared in Example 1 will be scanned by electron microscope, and the scanning results are shown in figure 2 .

[0032] by figure 2 It can be seen that Y 0.95 F 3 ,0.05Ce 3+ The product is a short-rod aggregated nanomaterial with a high degree of aggregation and uniform disper

Example Embodiment

[0035] Example 3: Stability experiment:

[0036] Take the Y prepared in Example 1 0.95 F 3 :0.05Ce 3 The finished nano-particle phosphor was placed in an ordinary sealed plastic bag for 3 months, and then taken out after 3 months for XRD testing. The experimental results showed that the XRD diffraction pattern did not change significantly, and the product components can be considered unchanged. The fluorescence intensity is compared with 0 days, the similarity is over 99%, and the luminous intensity is basically unchanged, so it can be considered that this product has good light stability.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap