Connecting clamping buckle used for photovoltaic assembly frame

A photovoltaic module and frame technology, applied in the field of photovoltaic module manufacturing, can solve problems such as water resistance that has not been effectively solved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

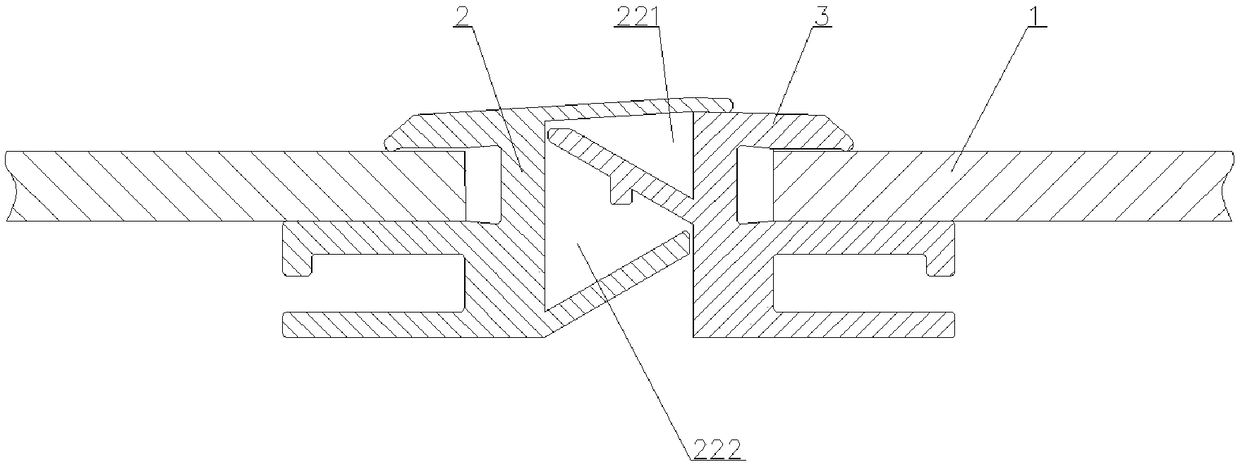

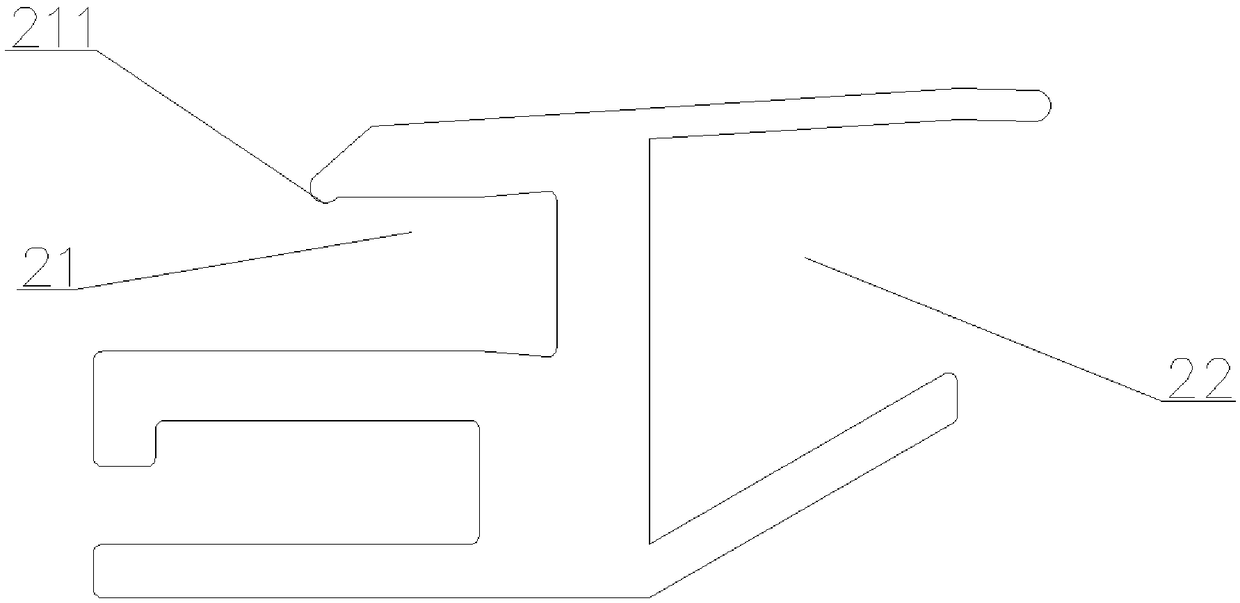

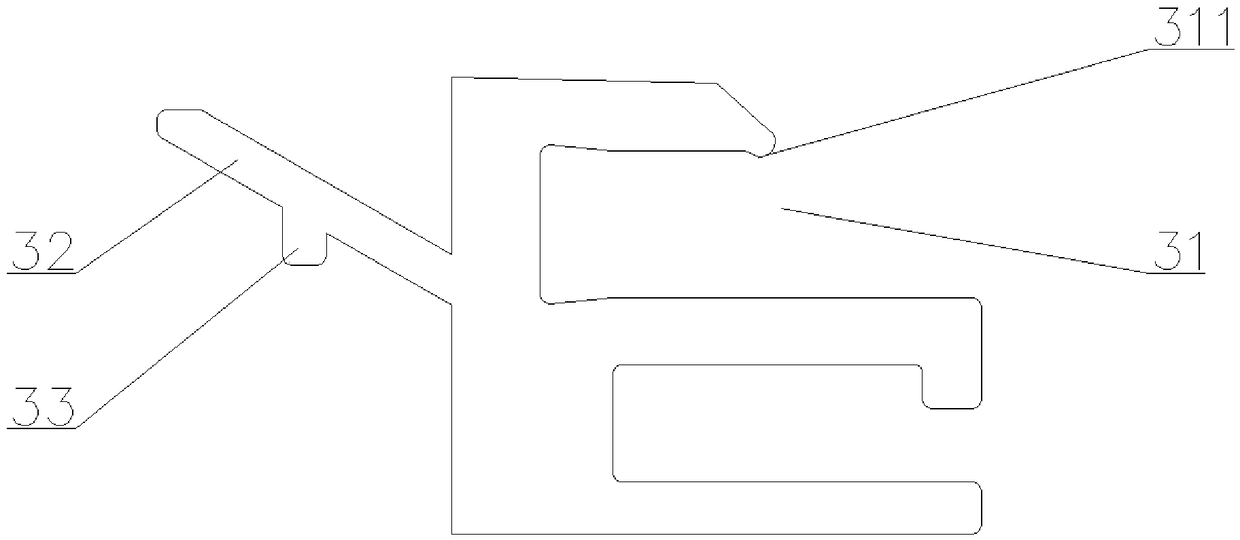

[0032] Below in conjunction with specific embodiment, content of the present invention is described in further detail, figure 1 , figure 2 , image 3 A schematic diagram of assembly in an embodiment of the connection buckle used for the photovoltaic module frame in the present invention, and a structural schematic diagram of the left and right fasteners of its constituent parts are respectively shown. like figure 1 As shown in , the connecting buckle is composed of a left engaging part 2 and a right engaging part 3 . A first photovoltaic panel placement groove 21 is opened on the left fastener 2, and a second photovoltaic panel placement groove 31 is opened on the right fastener 3. The first photovoltaic panel placement groove 21 is connected with the second photovoltaic panel The placement grooves 31 are arranged opposite to each other. A flow guiding groove 22 is also arranged on the left engaging part 2 . The bottom wall of the diversion groove 22 is inclined upwards, an

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap