Automatic processing equipment for sole vulcanization

A processing equipment, automatic loading and unloading technology, applied in the direction of household components, household appliances, other household appliances, etc., can solve problems such as the problem of mold movement that cannot be solved, achieve convenient operation and maintenance, improve overall stability, and uniform force. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0036] Example 1

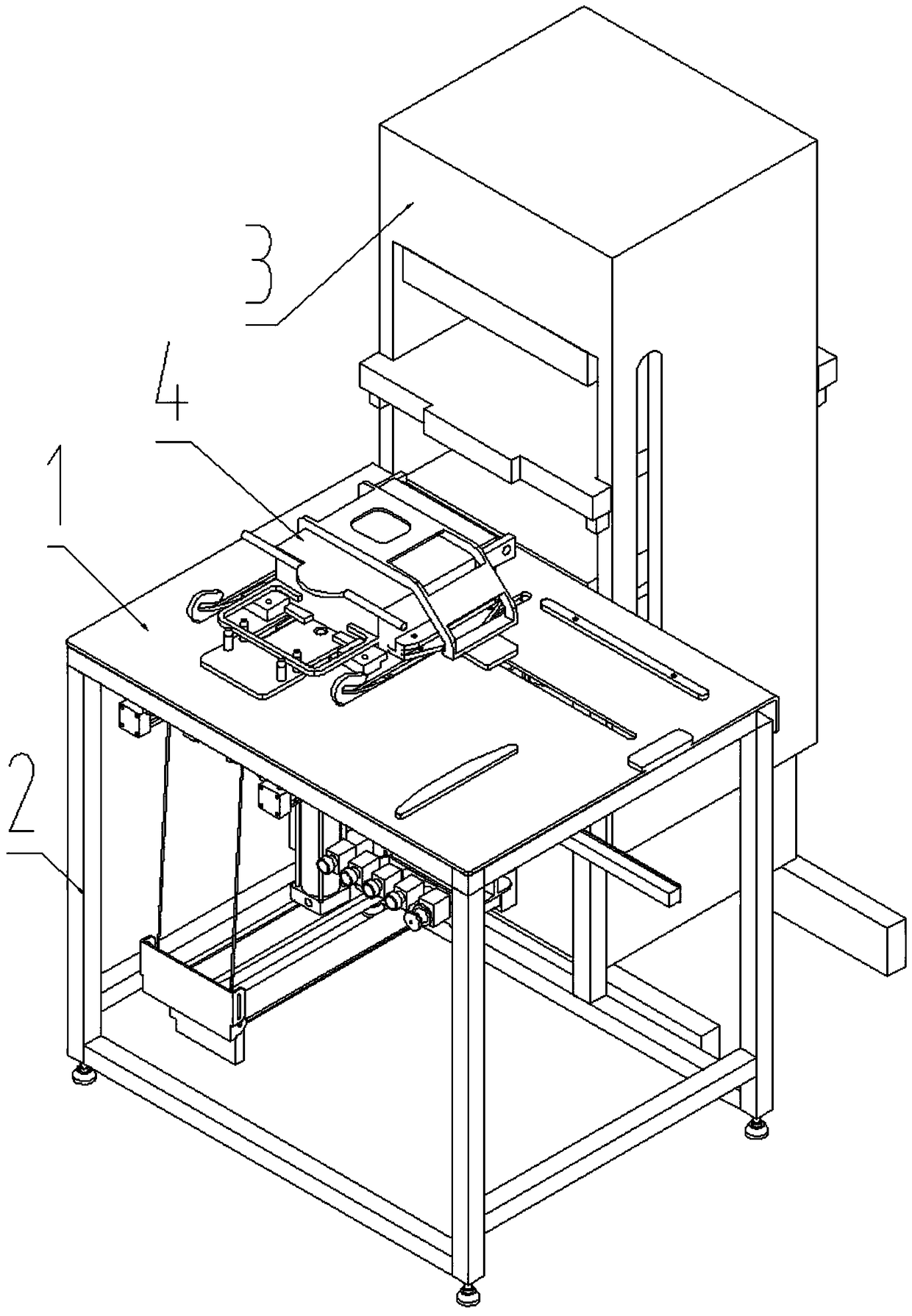

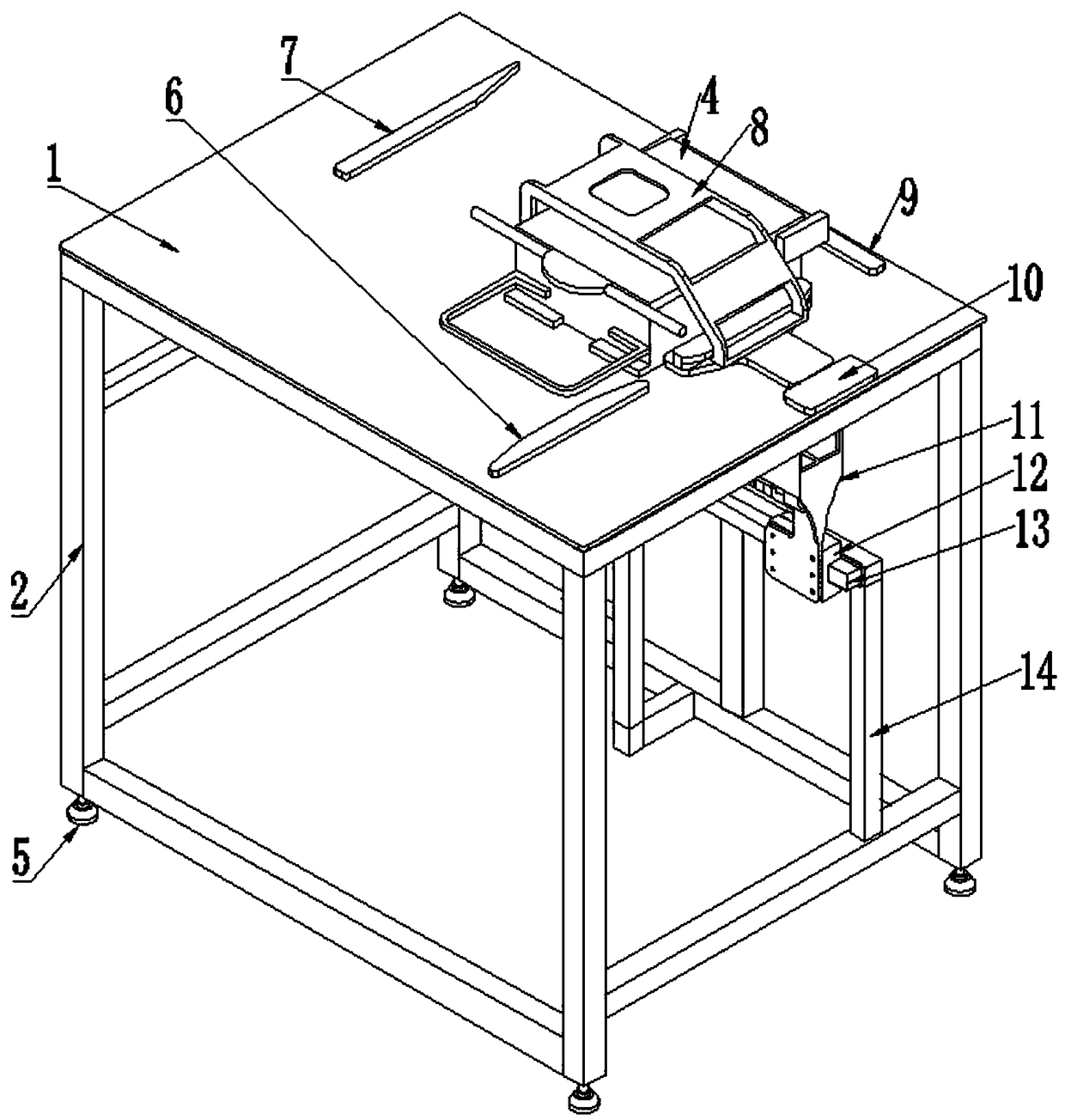

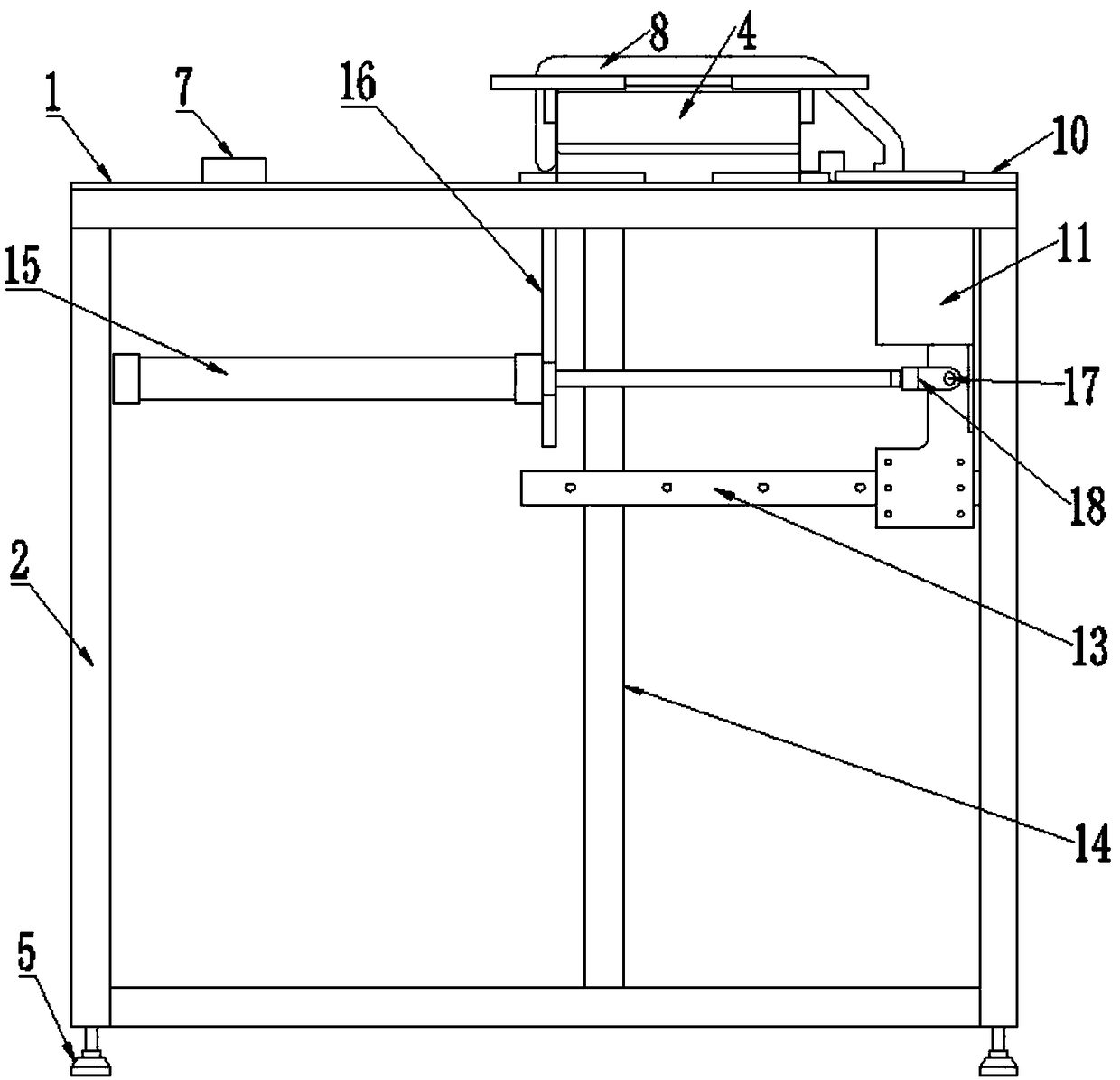

[0037] Such as Figure 1 to Figure 5 As shown, an automated processing equipment for shoe sole vulcanization includes a support plate 1, a frame 2, a heating furnace 3, a mold 4, an automatic mold loading and unloading mechanism, an automatic mold opening mechanism, and an automatic mold pushing and pulling mechanism. The support plate 1 is installed horizontally On the frame 2, the support plate 1 includes a feeding area on the left and a mold loading and unloading area on the right. The heating furnace 3 is set directly in front of the feeding area on the support plate 1 and is in contact with the support plate 1. The automatic loading and unloading mechanism is provided between the feeding area on the support plate 1 and the mold loading and unloading area, and the mold automatic lid opening mechanism and the mold automatic pushing and pulling mechanism are provided in the feeding area on the support plate 1;

[0038] The automatic mold assembly and disassembly

Example Embodiment

[0047] Example 2

[0048] Such as Figure 1 to Figure 5 As shown, an automated processing equipment for shoe sole vulcanization includes a support plate 1, a frame 2, a heating furnace 3, a mold 4, an automatic mold loading and unloading mechanism, an automatic mold opening mechanism, and an automatic mold pushing and pulling mechanism. The support plate 1 is installed horizontally On the frame 2, the support plate 1 includes a feeding area on the left and a mold loading and unloading area on the right. The heating furnace 3 is set directly in front of the feeding area on the support plate 1 and is in contact with the support plate 1. The automatic loading and unloading mechanism is provided between the feeding area on the support plate 1 and the mold loading and unloading area, and the mold automatic lid opening mechanism and the mold automatic pushing and pulling mechanism are provided in the feeding area on the support plate 1;

[0049] The automatic mold assembly and disassembly

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap