Garbage compression dehydrator

A technology of garbage compression and dehydrator, which is applied in the direction of garbage drying, drying solid materials, and drying solid materials without heating. Good, easy to operate and maintain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

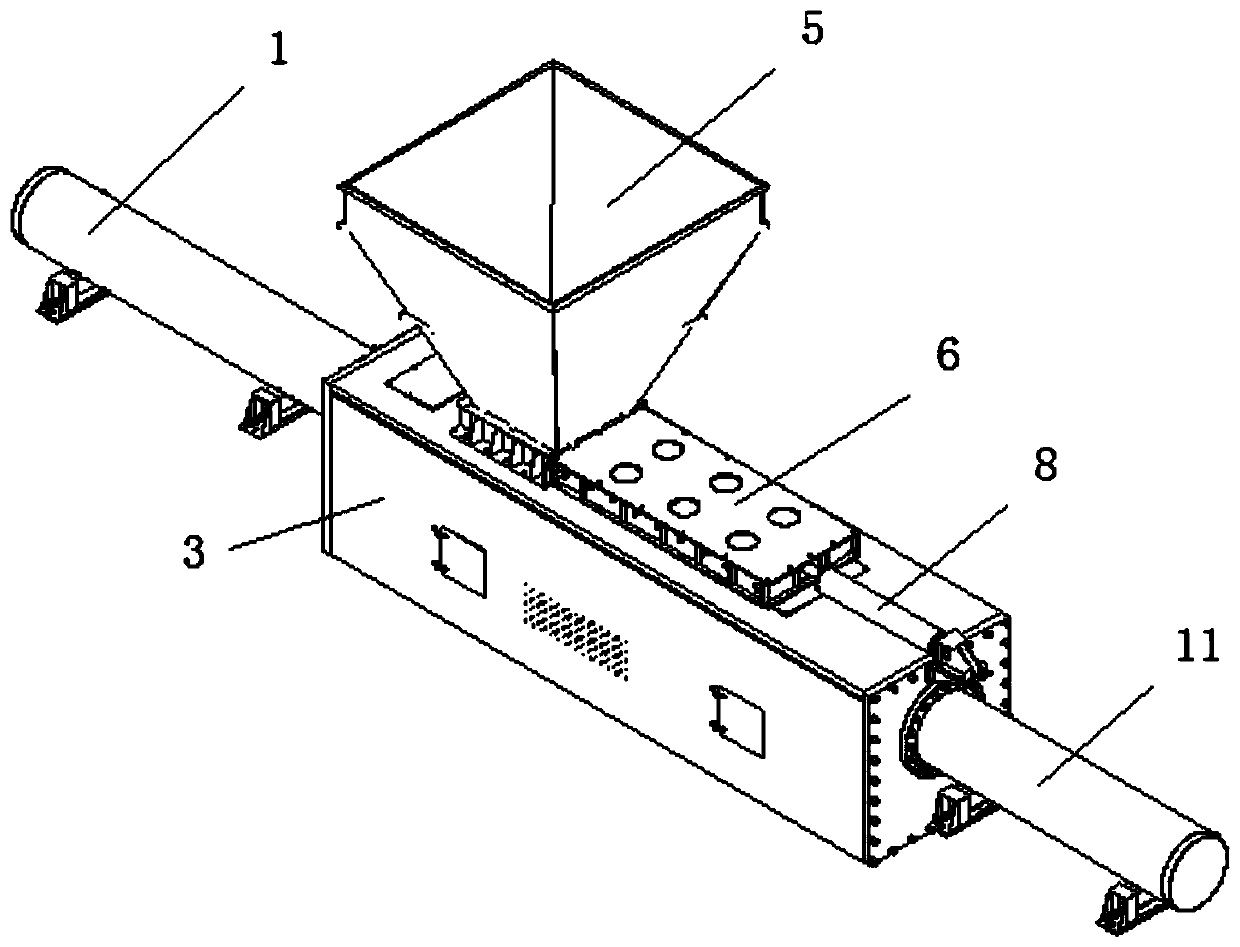

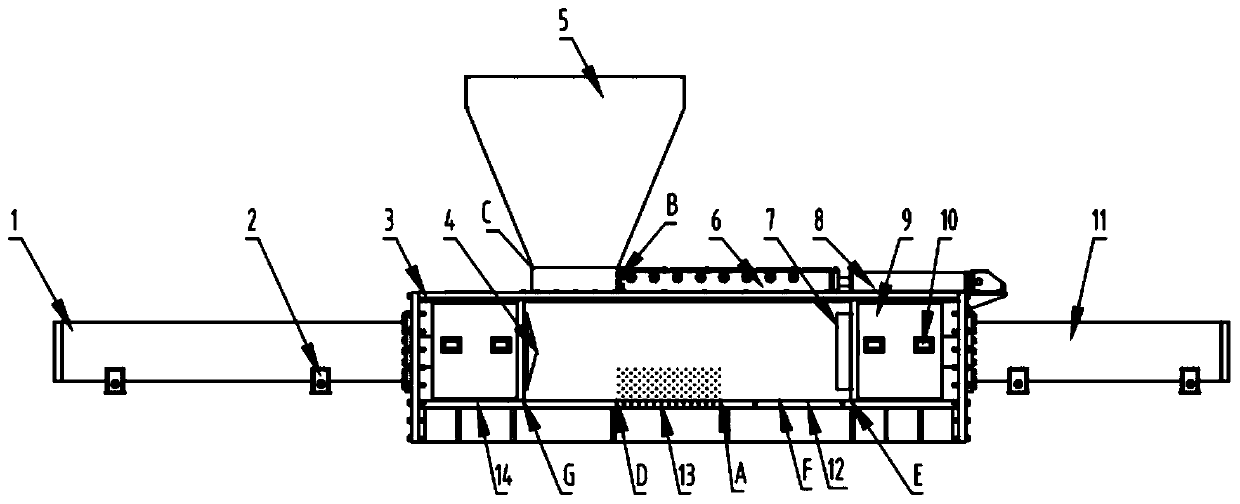

[0018] Such as figure 1 , 2 As shown, a garbage compression dehydrator includes a box body 3, and ribs are installed under the bottom plate of the box body 3 to play a role of strengthening and supporting. A sliding device 9 is slidably installed on the left and right sides of the inside of the box body 3. A number of rollers 10 are installed on the upper and lower, front and rear surfaces of the sliding device 9. In this embodiment, four are installed on the upper and lower ends. Two rollers 10 are installed on the front and rear surfaces of the roller 10 respectively. The inner side wall of the box body 3 is provided with a sliding groove matched with the roller 10 to ensure the smooth movement of the sliding device 9 so that the roller 10 does not jam during the movement.

[0019] The left end of the sliding device 9 on the left side is bolted to an oil cylinder 1 and a plug 4 is installed on the right end. The oil cylinder 1 passes through the left side wall of the box 3 and is

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap