Flywheel energy storage mixed type superconducting magnetic bearing

A flywheel energy storage and hybrid technology, applied in the field of magnetic bearings, can solve the problems of insufficient radial stiffness, short life, large loss, etc., and achieve the effect of suppressing radial pendulum, improving performance, and improving loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

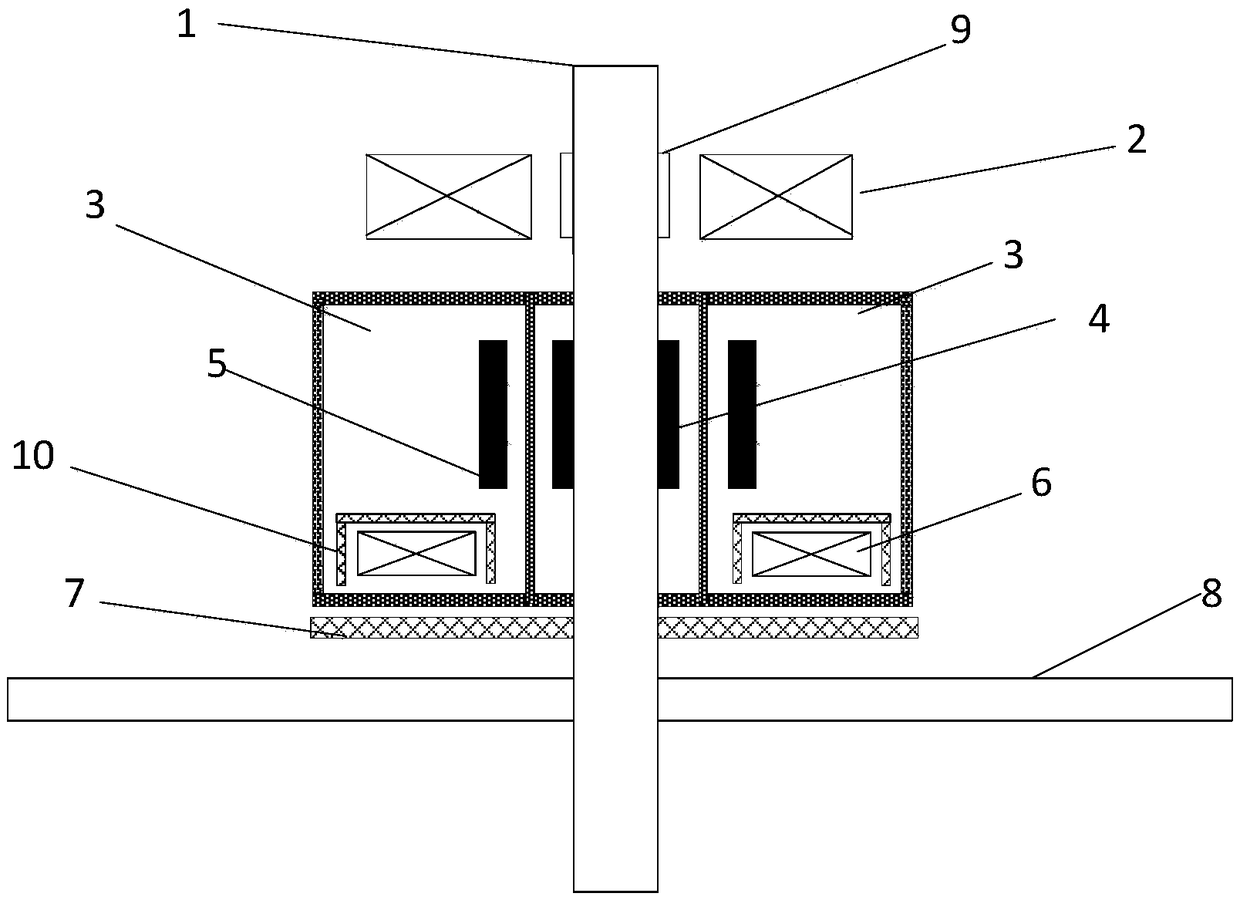

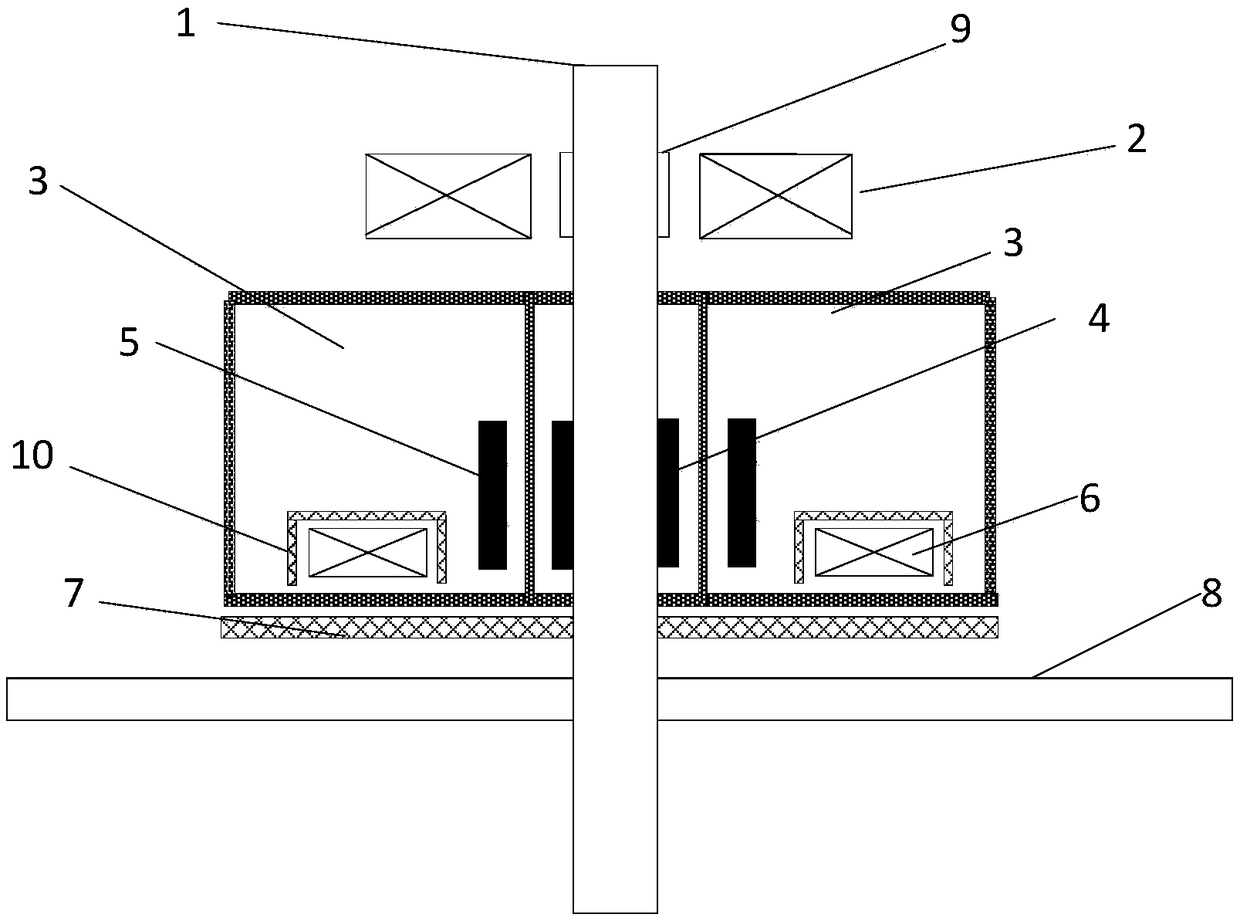

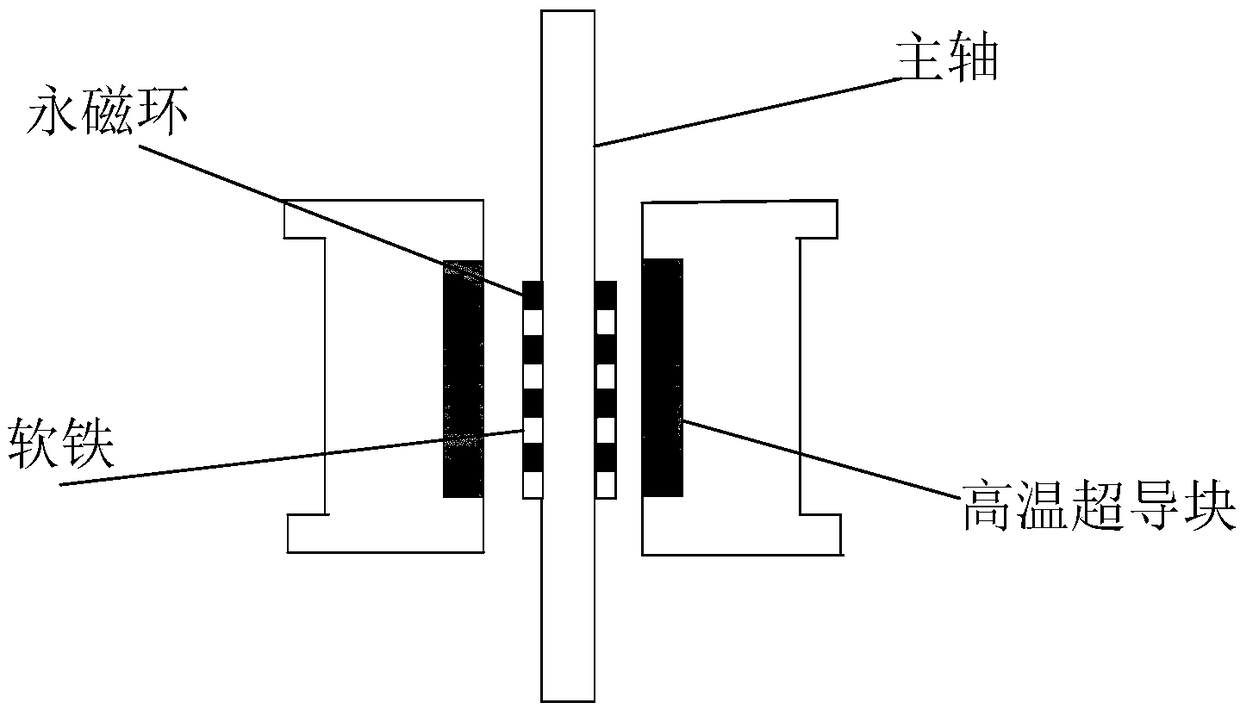

[0029] figure 1 It is a structural diagram of Embodiment 1 of the hybrid superconducting magnetic bearing for flywheel energy storage of the present invention. Such as figure 1 As shown, the hybrid superconducting magnetic bearing of the present invention consists of a stainless steel main shaft 1, a radial electromagnetic bearing stator 2, a low temperature Dewar 3, a superconducting bearing permanent magnet rotor 4, a superconducting bearing block stator 5, and a superconducting bearing coil stator 6 , superconducting bearing ferromagnetic suction disk rotor 7, flywheel 8, radial electromagnetic bearing ferromagnetic ring rotor 9, and superconducting bearing iron core yoke 10.

[0030] The radial electromagnetic bearing stator 2 is installed on the upper part of the stainless steel main shaft 1, the radial electromagnetic bearing stator 2 surrounds the radial electromagnetic bearing ferromagnetic ring rotor 9, the radial electromagnetic bearing ferromagnetic ring rotor 9 is se

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap