Wall type composite damper capable of improving lateral resistance performance of modularized building structure and manufacturing method

A compound damping and building structure technology, which is applied in the direction of building components, buildings, building types, etc., can solve the problem that metal dampers and viscous dampers cannot be well applied to modular building structures, and the manufacturing process of viscous dampers is complicated, Viscous fluids are prone to leakage and other problems, achieving obvious energy dissipation effects, good energy dissipation performance, and small plane size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

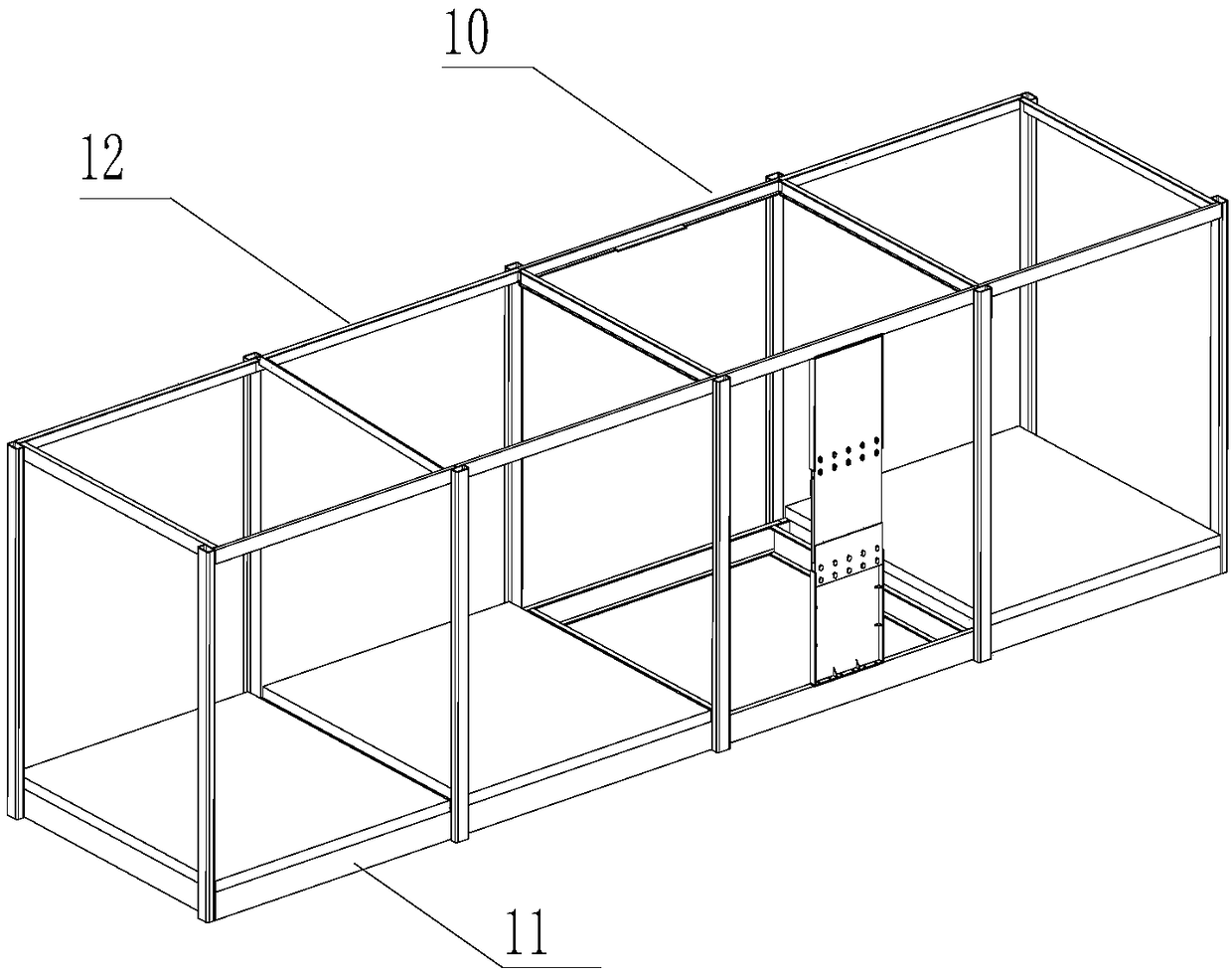

[0046] Such as figure 1 As shown, this embodiment provides a wall-type composite damper for improving the lateral resistance of a modular building structure, including an upper structure and a lower structure, wherein the upper structure is connected to the upper beam of the modular structural frame by high-strength bolts , The lower structure is connected with the module lower beam of the modular structural frame through high-strength bolts.

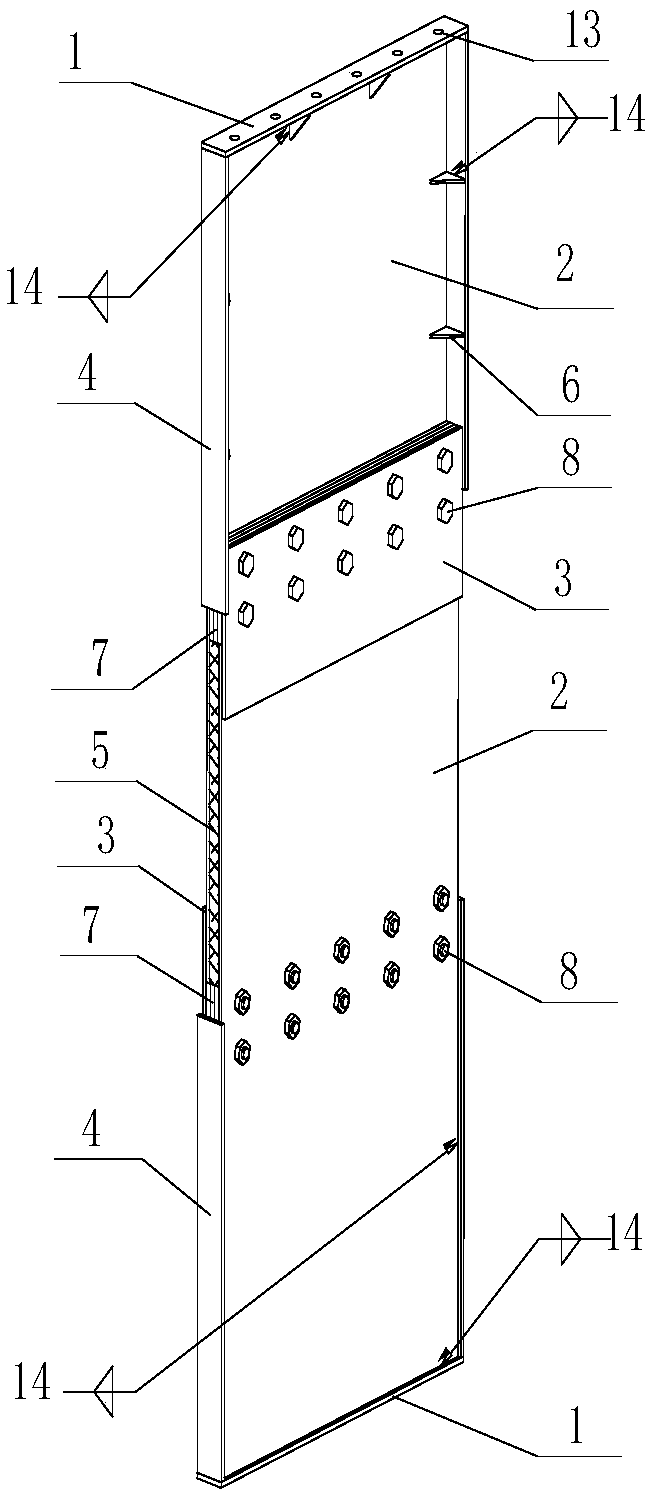

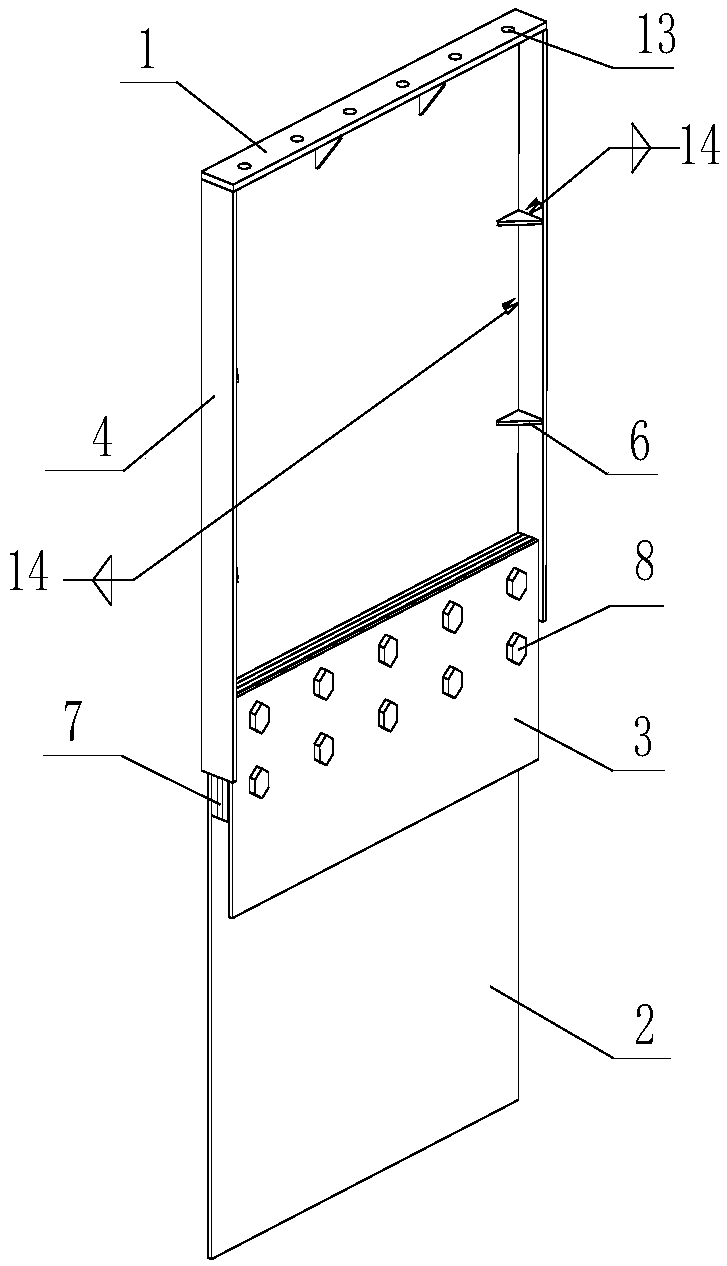

[0047] Such as Figure 2 to Figure 14 As shown, the wall composite damper includes an upper structure and a lower structure; the upper structure includes an end plate 1, a connecting plate 2, a splint 3, a copper bar 9, a rib 4, a metal gasket 7 and a stiffener 6, the upper structure and the lower The structure includes an end plate 1, a connecting plate 2, a splint 3, a rib 4, a groove 15 and a copper sheet 9; one end of the connecting plate 2 is connected to the end plate, and a splint 3 and a connecting plate 2 are arranged near the middle

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap