Weighing method based on force acquisition from amplitude varying steel wire rope

A wire rope, weighing technology, applied in the direction of load hanging components, transportation and packaging, can solve the problems of inconvenient installation, hidden dangers, affecting the overall structure, etc., to achieve the effect of convenient installation and saving man-hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0046] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

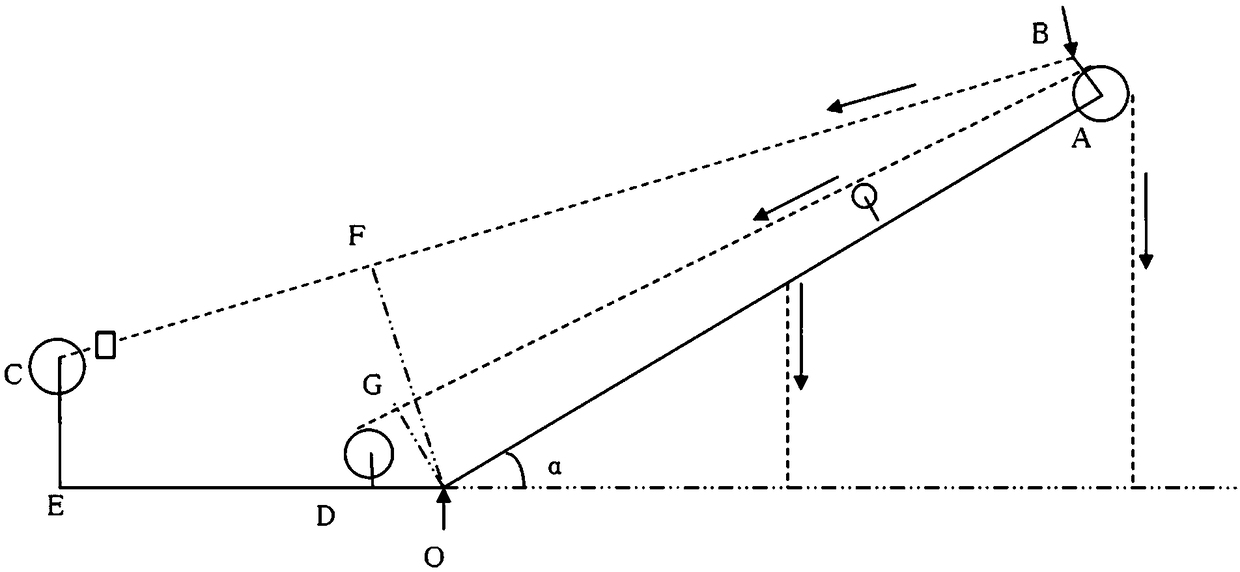

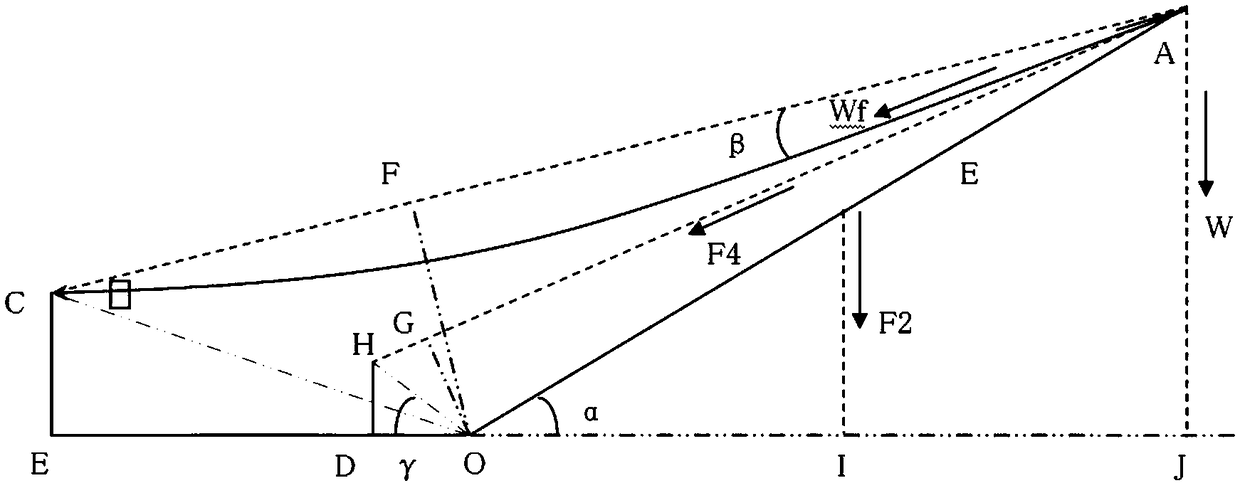

[0047] The luffing force refers to taking the tension on the luffing steel wire rope. It adopts the ordinary plate ring sensor and installs it on the fixed end of the luffing rope or on the bracket of the luffing pulley block. Refer to the attached figure 1 . According to the torque balance relationship of luffing rope tension, hoisting rope tension, boom self-weight, and load gravity, multiple parameters are determined through the operation of the commissioning site, and then the load gravity is calculated according to a set of algorithms, so as to achieve the weighing and weight of the load. Moment

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap