Sausage with fermentation flavor and manufacturing method thereof

A technology of fermented flavor and production method, which is applied in the direction of food ingredients as taste improvers, food ingredients as odor improvers, food drying, etc. It can solve the problems of poor tightness of meat grains, uneven mixing, and too soft taste, etc., to achieve The taste is delicate, the production process is safe and environmentally friendly, and the raw materials are simple and easy to obtain.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

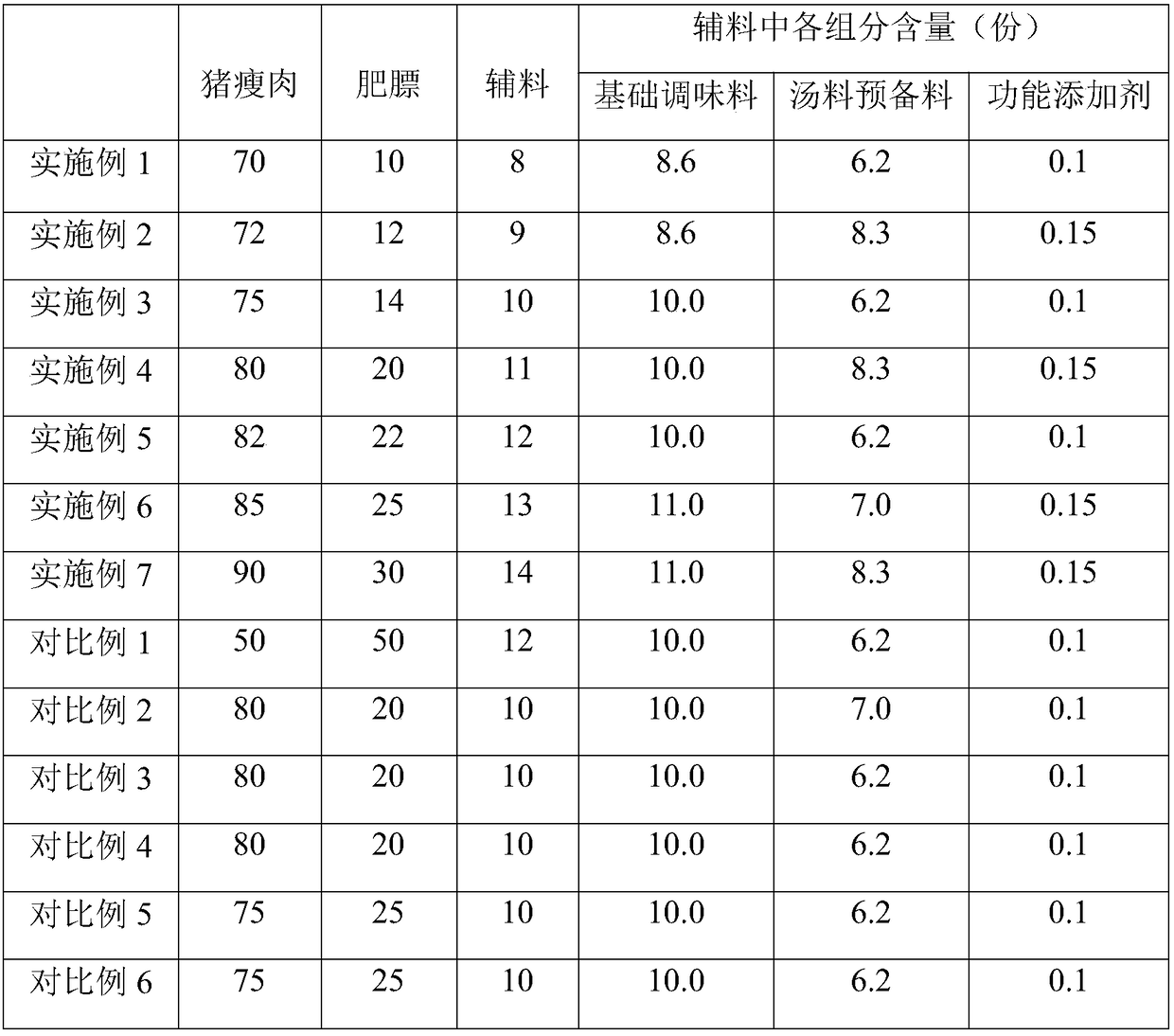

[0050] Example 1 Method for making sausage with fermented flavor

[0051] The specific preparation method includes the following steps:

[0052] S1. Raw material pretreatment

[0053] S11. Pre-treatment: first cut the lean pork (selected from fresh pork forelegs) by hand to remove the fascia, and select lean buttocks to mince the meat with a diameter of 8mm (using an orifice plate with a diameter of 8mm) to obtain Pretreatment of lean meat pieces;

[0054] S12. Pretreatment of fat fat: cut the fat fat into 5×5×5mm with a dicing machine 3 Then rinse with 70℃ hot water for 3 minutes, and then use flake ice to reduce the fat fat temperature to 5℃ to obtain pre-treated fat;

[0055] S2. Pretreatment of auxiliary materials:

[0056] S21. Soup pretreatment: use bone broth and spice bags to simmer for 30 minutes at a slightly boiling temperature and time, let cool and filter, the resulting soup is mixed with sorghum wine, and then placed in a low-temperature cooling room for later use;

[0057] S2

Example Embodiment

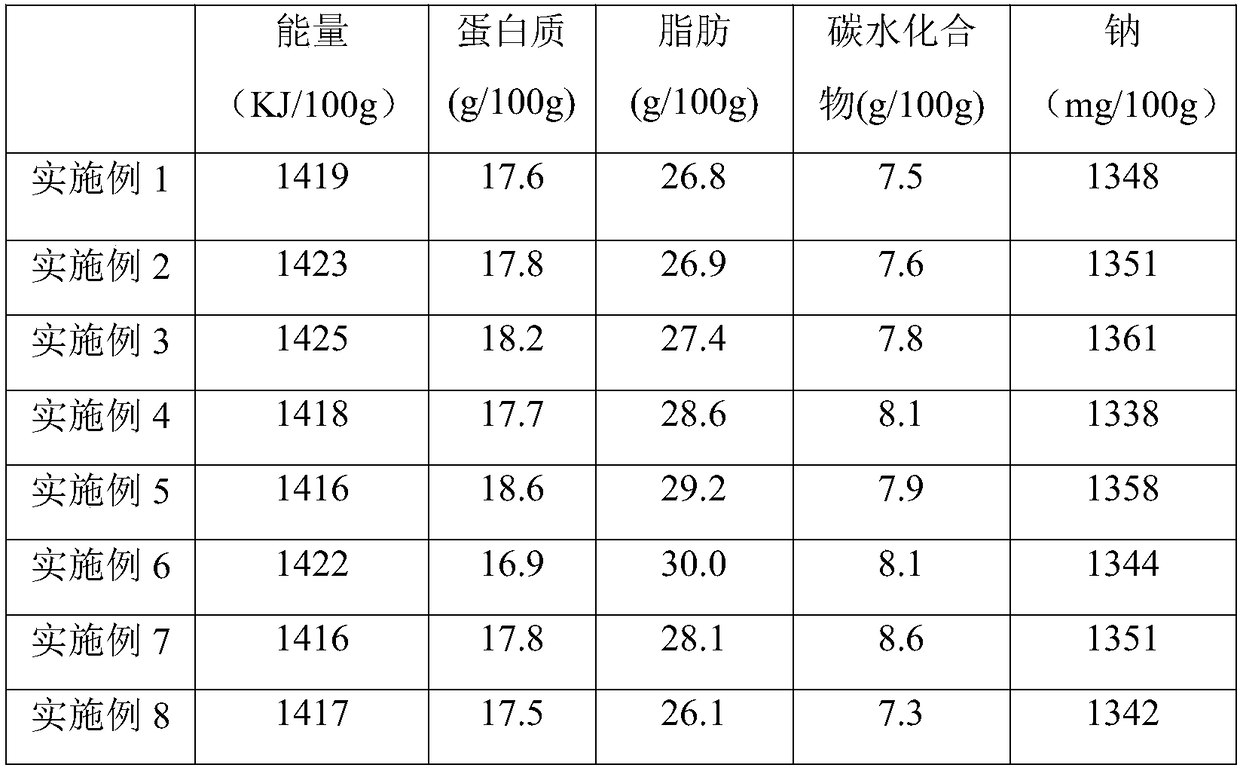

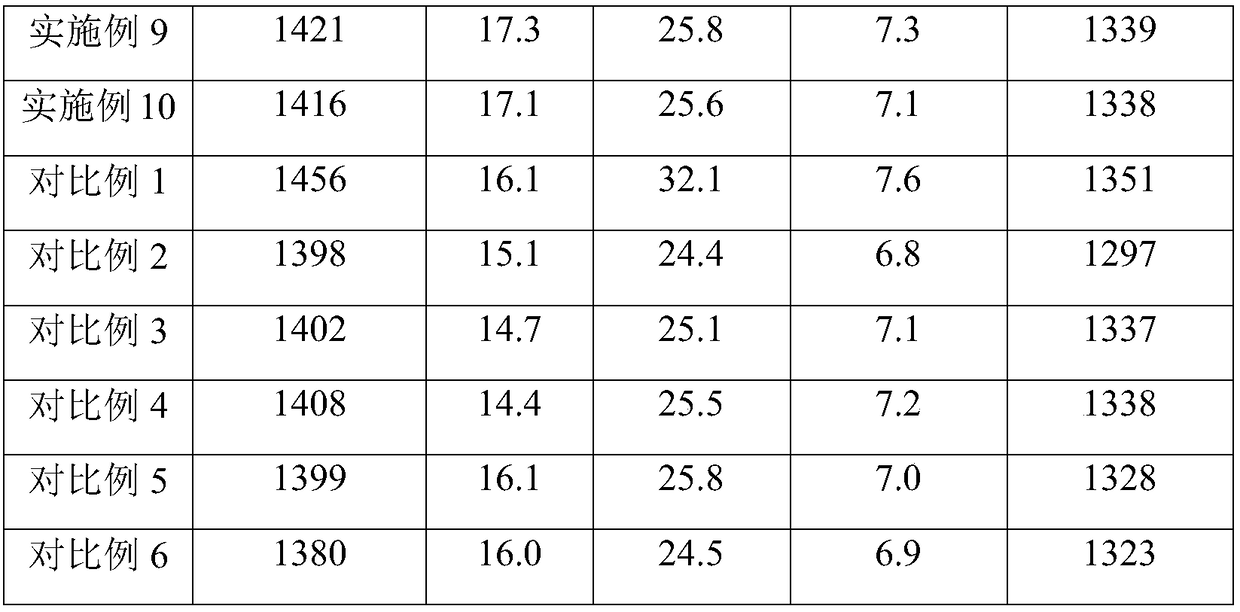

[0062] Example 2 Method for making sausage with fermented flavor

[0063] The specific preparation method and steps are the same as in Example 1. The difference is: weigh the components as shown in Table 1. The basic seasoning includes 0.6 parts of salt, 9.0 parts of sugar and 0.2 parts of monosodium glutamate; the soup preparation includes 4.5 parts of bone soup, 0.2 parts of licorice, 2.5 parts of sorghum liquor; functional additives include 0.1 part of sodium D-isoascorbate and 0.002 part of sodium nitrite. The nutritional ingredients of the finished sausage with fermented flavor are shown in Table 2.

Example Embodiment

[0064] Example 3 Preparation method of sausage with fermented flavor

[0065] The specific preparation method and steps are the same as in Example 1. The difference is: weigh the components as shown in Table 1. The basic seasoning includes 0.75 parts of salt, 10.0 parts of sugar and 0.25 parts of MSG; the soup is prepared The ingredients include 5.0 parts of bone soup, 0.3 parts of licorice, and 3.0 parts of sorghum liquor; the functional additives include 0.15 parts of sodium D-isoascorbate and 0.003 parts of sodium nitrite. The nutritional ingredients of the finished sausage with fermented flavor are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap