Rapid tooth roller replacement rotation shaft device used on tooth roller type pulverizer

A technology of a rotating shaft device and a pulverizer, which is applied in grain processing and other directions, can solve the problems of wasting time and complicated operation, and achieve the effects of high degree of automation, convenient operation and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

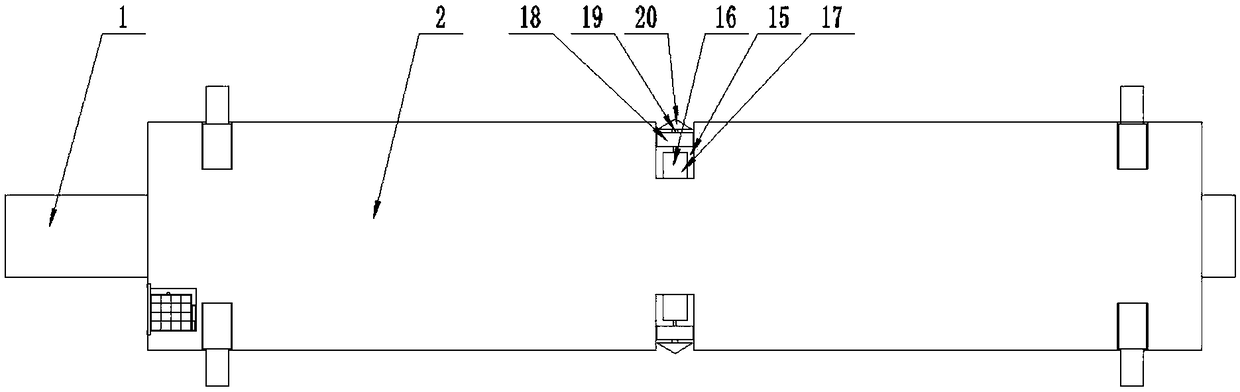

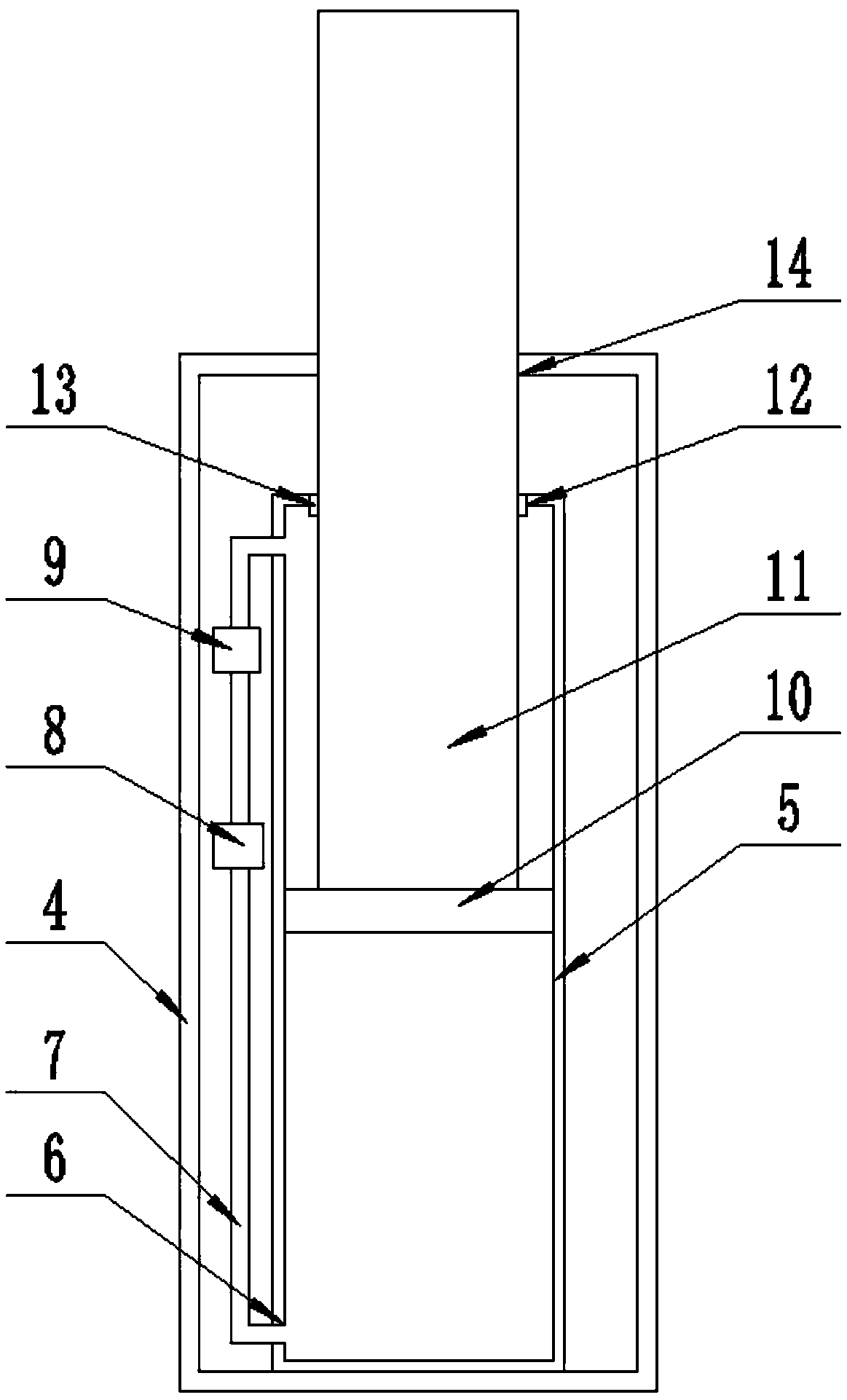

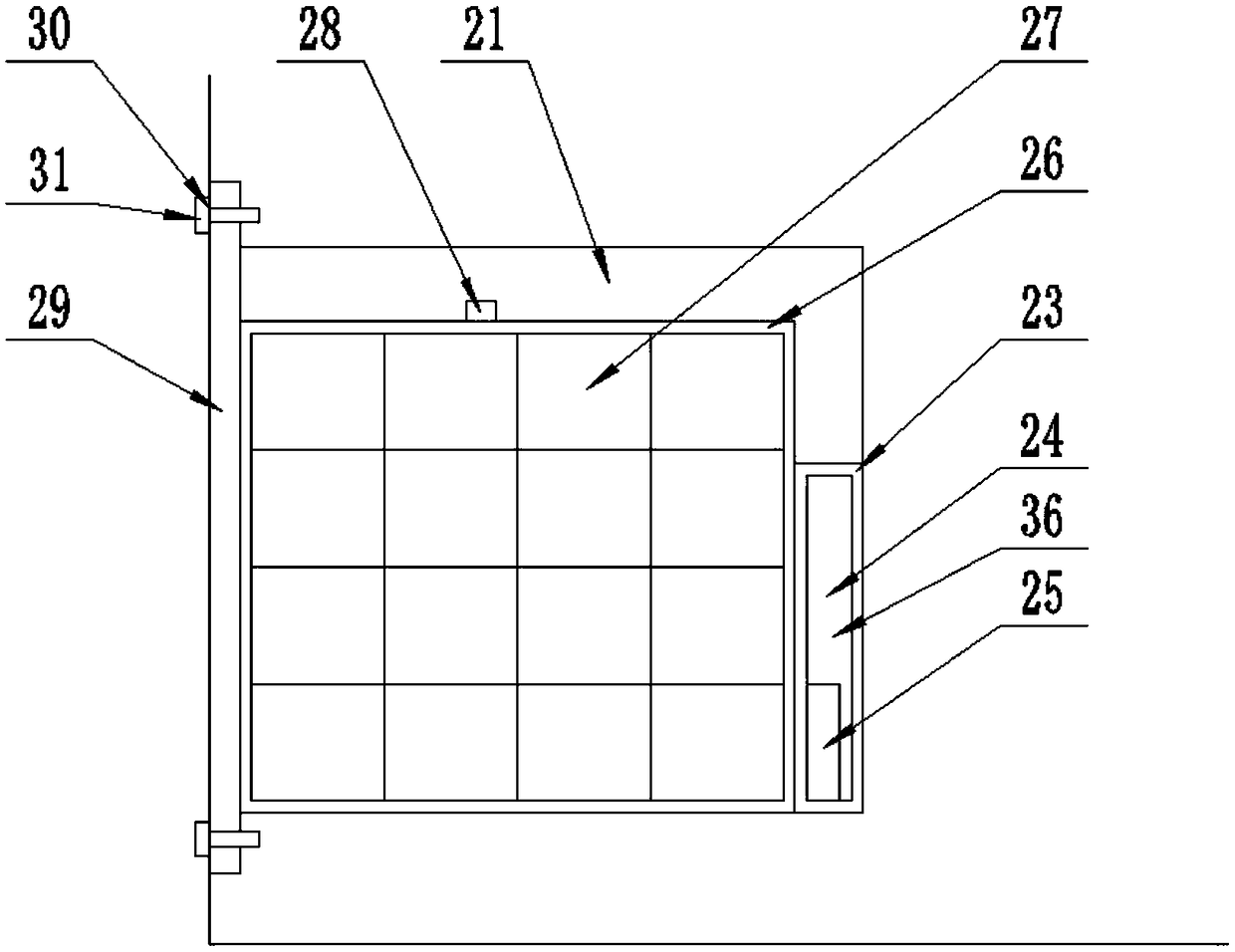

[0021] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-5 As shown, a rotating shaft device for quickly replacing the toothed rollers on a toothed roller pulverizer includes a rotating shaft 1 fixedly installed on the toothed roller pulverizer, and the rotating shaft 1 is provided with a hydraulically fixed toothed roller device. The hydraulically fixed toothed roller device consists of a polygonal fixed cylinder 2 fixedly connected to the rotating shaft 1 at the center of the rotating shaft 1, a number of oblique grooves 3 evenly distributed on the outer surface of the polygonal fixed cylinder 2, and located in the oblique groove 3. The fixed cylinder 4 whose lower end is fixedly connected with the oblique groove 3, the hydraulic cylinder 5 fixedly connected with the fixed cylinder 4 in the fixed cylinder 4, the two hydraulic oil ports 6 opened on the upper and lower ends of the outer surface of the hydraulic cylinder 5,

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap