Stainless steel grinding fluid containing silicon oxide and diamond and preparation method of stainless steel grinding fluid

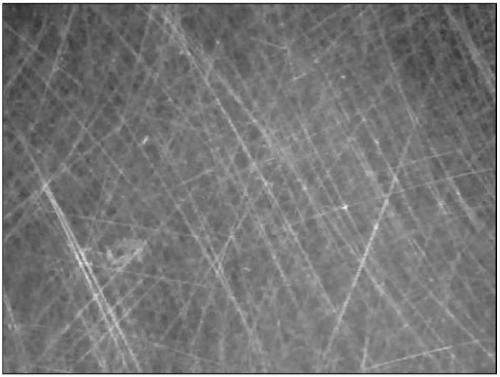

A technology of stainless steel and abrasive liquid, which is applied in the field of materials, can solve the problems of easy sedimentation of abrasive particles, affect the effect of grinding and polishing, and high content of abrasive particles, and achieve the effect of being beneficial to subsequent finishing, reducing sedimentation, and less scratches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6

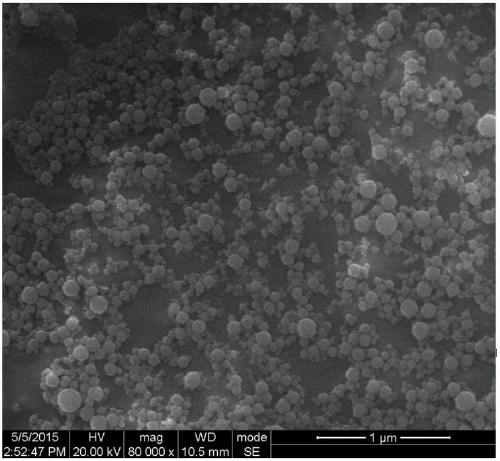

[0029] Embodiment 1~6 contains the stainless steel abrasive liquid of silicon oxide and diamond

[0030] Made from the raw materials and their weight percentages shown in Table 1.

[0031] Table 1 Embodiment 1~6 contains silicon oxide and diamond stainless steel grinding liquid raw material and mass percentage content

[0032]

[0033] Preparation:

[0034] Take a corresponding amount of silicon oxide polishing liquid, add a corresponding amount of water, stir evenly, then add a corresponding amount of suspending agent, stir evenly, and finally add a corresponding amount of diamond powder, stir until uniform, and ultrasonically oscillate for 10 to 60 minutes to obtain the product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap