Method for monitoring top oil temperature of oil-immersed transformer

A technology for oil-immersed transformers and top layer oil temperature, which is applied in the direction of instruments, thermometers, measuring electricity, etc., can solve the problems of transformer overload operation, deviation, etc., and achieve comprehensive, accurate and universal monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

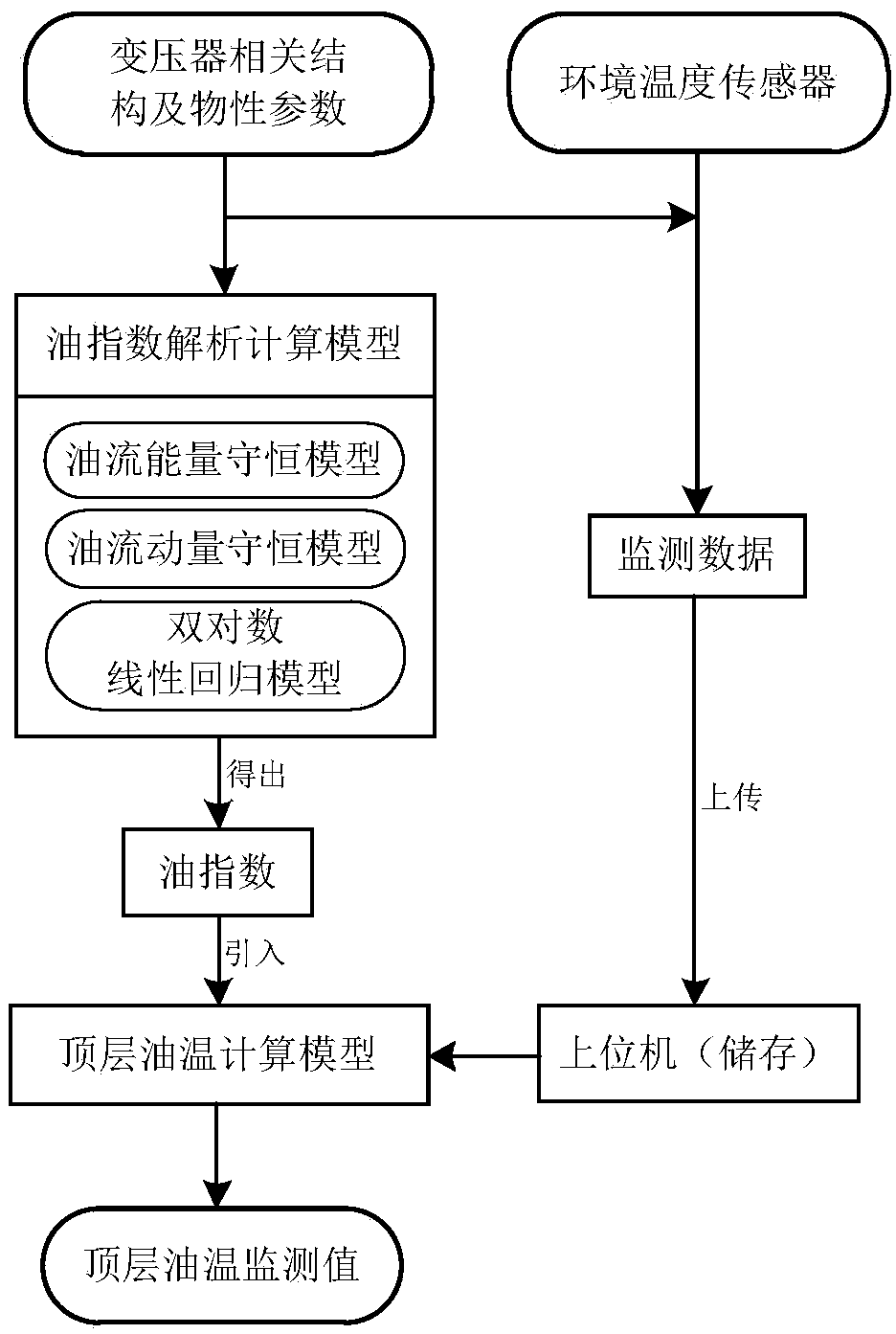

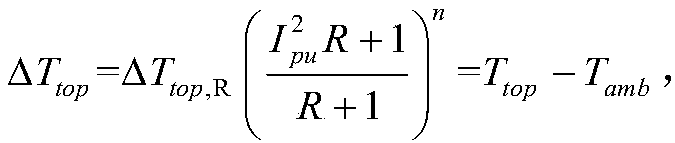

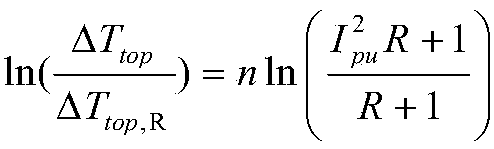

Method used

Image

Examples

Embodiment Construction

[0044] The present invention is further described below.

[0045] The first step is to obtain the known structure and physical parameters of the oil-immersed transformer:

[0046] Height difference Δh between hot and cold cores, winding height h w , radiator height h r , Winding vertical oil channel thermal hydraulic diameter D w , Radiator oil channel thermal hydraulic diameter D r , oil specific heat capacity c oil , air specific heat capacity c air , oil density ρ oil , air density ρ air , oil thermal expansion coefficient β oil , Winding along the drag coefficient f w , The drag coefficient f along the radiator r , the total heat transfer coefficient of the radiator U, the flow area of the winding area A w , Radiator circulation area A r , Radiator effective heat dissipation area A R , temperature difference index λ, ambient temperature T amb .

[0047] The second step is to solve the unknown quantities to be determined, including: the oil flow volume flow ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap