A stainless steel positioning shaft for high-speed railways

A stainless steel and positioning shaft technology, applied in the direction of overhead lines, etc., can solve the problems of low strength and corrosion resistance that cannot be compared with stainless steel, and achieve the effects of small bearing area, superior performance, and excellent plasticity and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0014] The present invention will be further described in detail below in conjunction with the drawings:

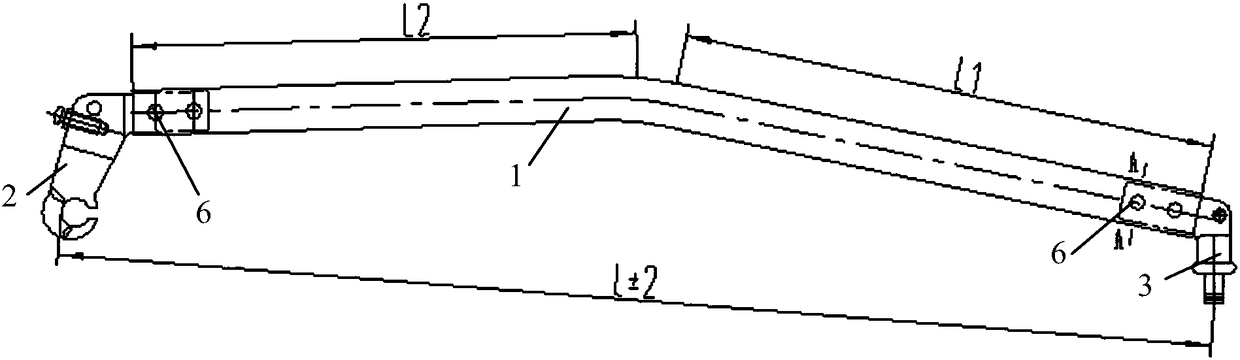

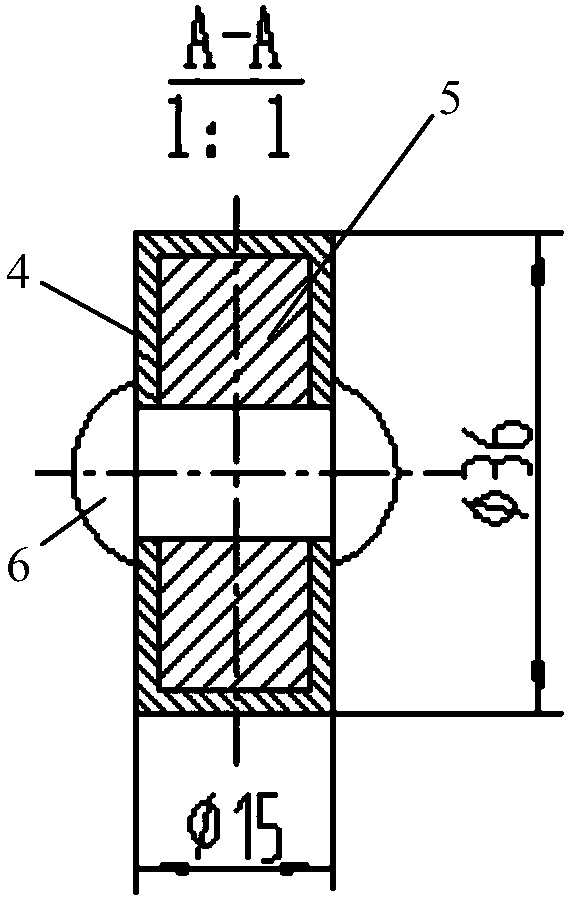

[0015] See figure 1 with figure 2 , The stainless steel positioning shaft for high-speed rail of the present invention includes a rod-shaped stainless steel body 1, at both ends of the rod-shaped stainless steel body 1, one end is fixedly connected with a stainless steel hook body 2, and the other end is fixedly connected with a stainless steel shaft 3; The middle of 1 is bent downward at an angle of 100 degrees. The stainless steel shaft 3 is arranged vertically downward in the axial direction; the stainless steel shaft 3 is a rectangular connecting sleeve 4 at the end connected to the rod-shaped stainless steel body 1, and the rod-shaped stainless steel body 1 is at the end connected to the stainless steel shaft 3. To be able to insert the rectangular end 5 of the rectangular connecting sleeve 4; the rectangular end 5 of the rectangular connecting sleeve 4 is fixed by stain

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap