Energy-saving type wall painting device

An energy-saving, wall technology, applied in construction, building structure, etc., can solve the problems of inability to achieve uniformity, leakage of paint slurry, high labor intensity, etc., to improve the quality of wall construction, construction quality improvement, operation handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0025] Example 1:

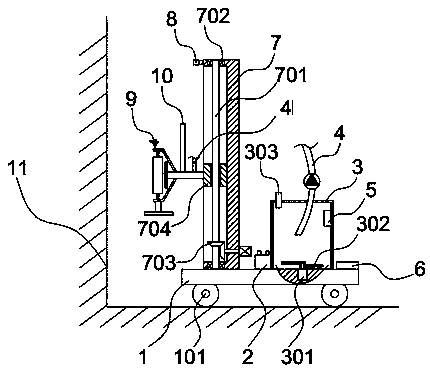

[0026] like Figure 1-4 As shown, the energy-saving wall painting device includes a bottom plate 1 on which a barrel 3 and a lifting plate 7 are respectively arranged above. The lifting plate 7 is provided with a lifting and lowering painting mechanism 9. The painting mechanism 9 passes through the discharge pipe 4 and the barrel. 3 is connected, the discharge pipe 4 is connected with a pump body, the bottom plate 1 is provided with a motor 301 whose output shaft is in the barrel 3, the output shaft is staggered with stirring blades 302 with different heights, and the upper part of the inner wall of the barrel 3 is connected at least with A monitor 5, with a computer 6 on the base plate 1. The wall 11 is painted by mechanical equipment instead of manual painting, which reduces the labor force and improves the painting quality of mechanical operation. The entire painting process is monitored by the computer 6, and the parameters of each component on the device

Example Embodiment

[0035] Example 2:

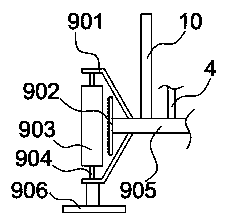

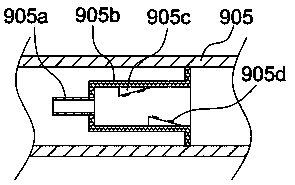

[0036] When the energy-saving wall painting device of the present invention actually works: pour the painted cement slurry raw materials into the barrel 3, stir the raw materials by the motor 301 to prevent the raw materials from sinking or layering, and push the device to the wall by the roller 101. Near 11, control the brushing distance, start the pump body on the discharge pipe 4 to extract the cement mortar and transport it into the connecting pipe 905, and spray the mortar from the nozzle 902 to drive the roller brush wheel 903 to rotate, and at the same time spray the brush slurry to the roller brush. Feeding is realized on the wheel 903, and the lifting mechanism 7 drives the screw rod 701 to rotate through the bevel gear set 703 to drive the lifting block 704 to go up and down, and drives the brush wheel 903 to go up and down to paint the wall 11. For the construction speed of the plastered wall, the drying device 10 can be used to dry the wall 11 to s

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap