Preparation method of black tea matcha

A technology of black tea and tea leaves, which is applied in the field of black tea to achieve the effect of unique flavor, uniform drying degree and reducing bitterness and astringency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

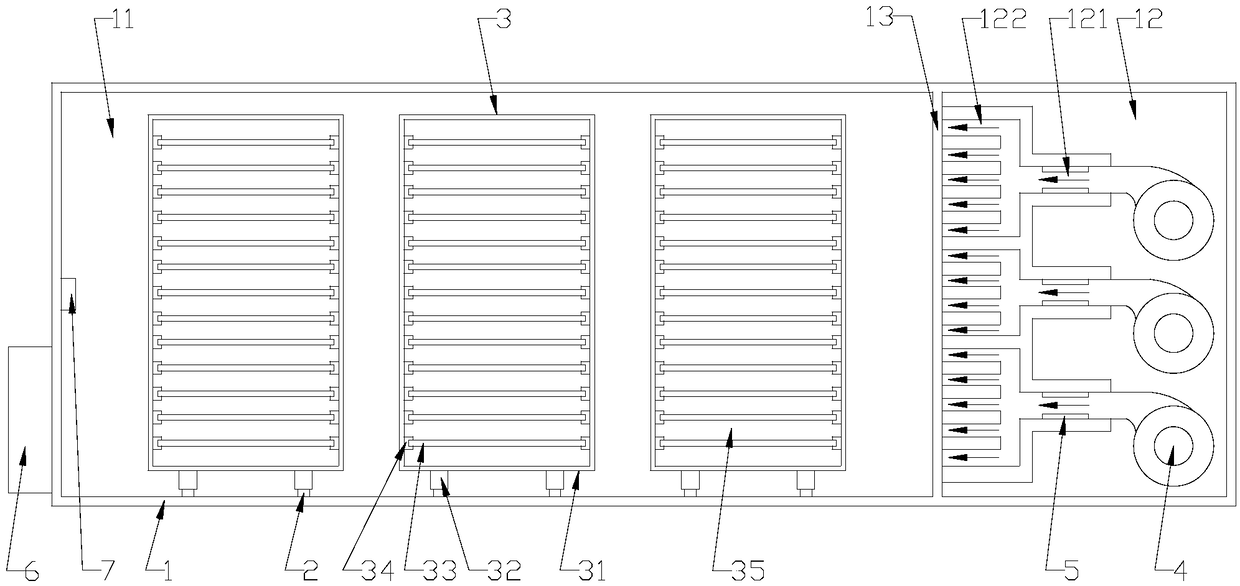

[0023] refer to figure 1 , the preparation method of a kind of black tea matcha of the present invention, comprises the steps:

[0024] a) Picking: picking fresh tea leaves with one bud and two leaves or one bud and three leaves;

[0025] b) Green drying: drying the picked tea leaves in the sun or under artificial light sources, at a temperature of 25-30°C, for 10-20 minutes;

[0026] c) Green spreading: put the sun-dried tea leaves in a ventilated place indoors for 1-2 hours at a temperature of 25-28°C;

[0027] d) Cutting leaves: using a shredder and a stem leaf separator to cut off the petiole and the main vein of the tea leaves after spreading green and separate them from the blade, and then chop the petiole, the main vein of the leaf vein and the blade respectively;

[0028] e) Withering: place the petioles, main veins and leaves after the cut leaves in the withering tank and cooperate with the blower to dissipate heat to wither until the water content of the tea leaves is

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap