Wire arranging frame for winding open type coil

A cable rack and open-type technology, applied in the field of cable racks, can solve the problems of iron core fixing and coil winding that are not suitable for open-type transformers, so as to avoid uneven distribution of turns, facilitate clamping, and ensure The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

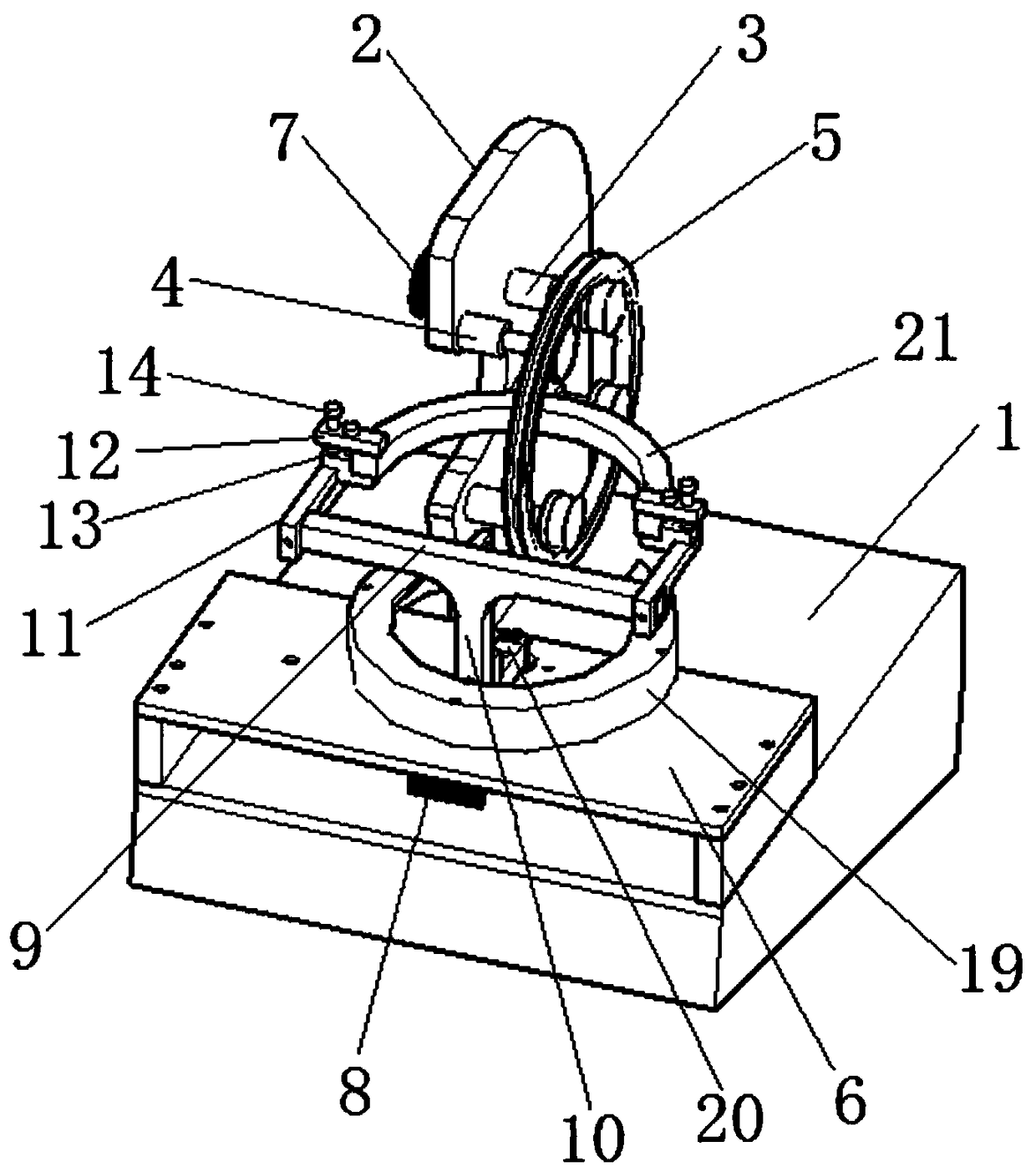

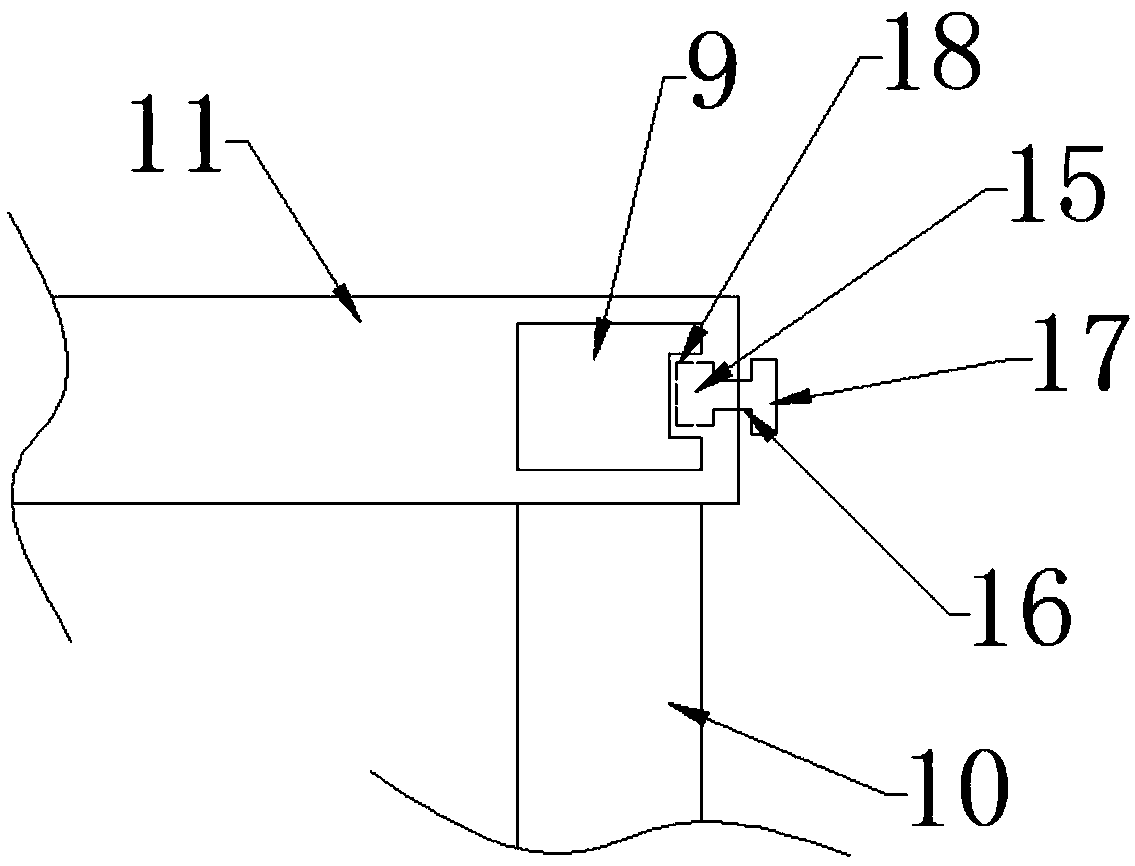

[0027] Such as figure 1 As shown, a cable rack for winding an open-type wire bag includes a base 1 and a controller. The base 1 is provided with a surrounding machine head 2, and the same side of the surrounding machine head 2 is provided with a drive that penetrates the body of the surrounding machine head 2. The shaft 3 and several supporting shafts 4, the end of the driving shaft 3 far away from the supporting shaft 4 is connected with the first motor 7, and the ends of the driving shaft 3 and the supporting shaft 4 on the same side around the machine head 2 are frictionally connected with a wire storage ring 5, It is characterized in that a horizontal sup

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap