A warehouse stock allocation management system and method

A management system and inventory technology, applied in the field of warehouse inventory allocation management system, can solve the problems of inventory allocation management relying on artificial memory and experience, restricting the accuracy of inventory allocation, inventory allocation efficiency, and being unable to further expand functions, etc., to shorten the distribution distance, The effect of avoiding wrong picking incidents and shortening delivery time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

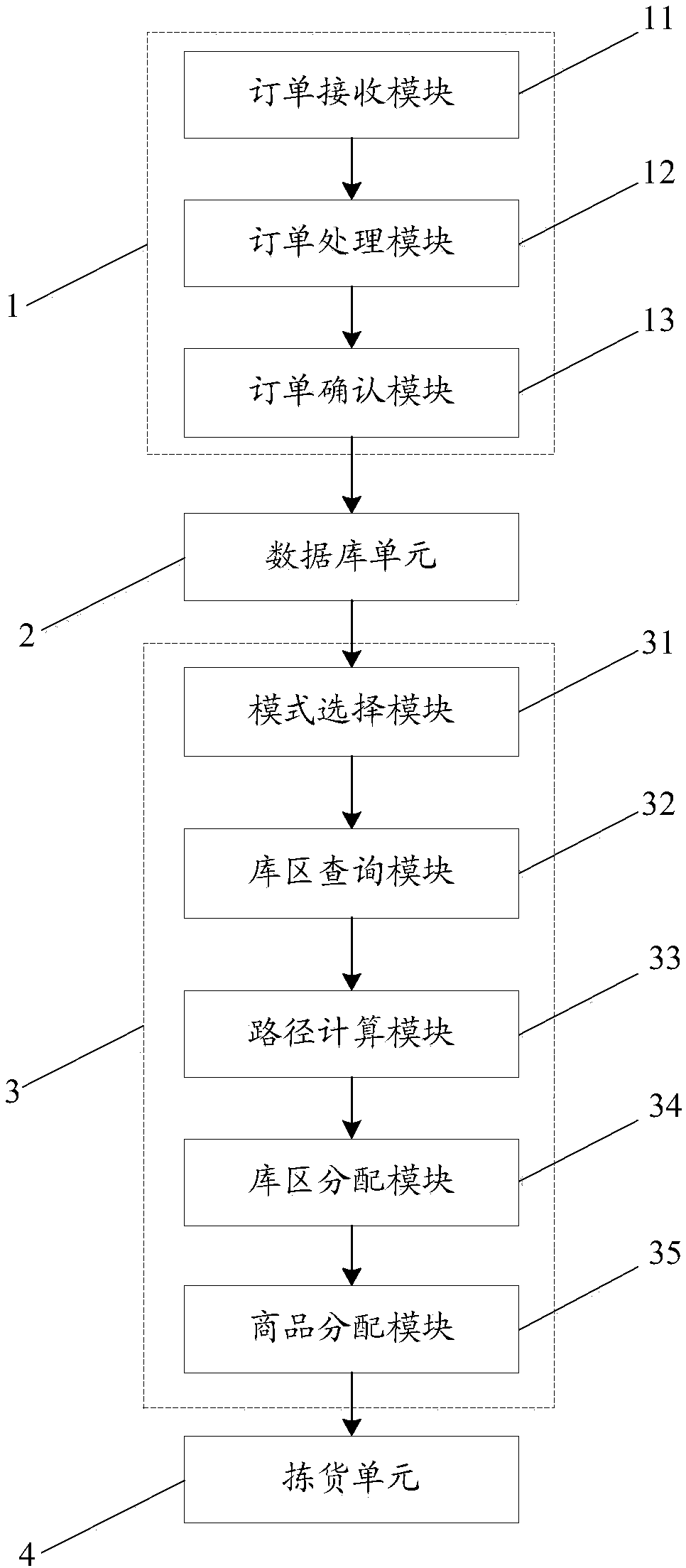

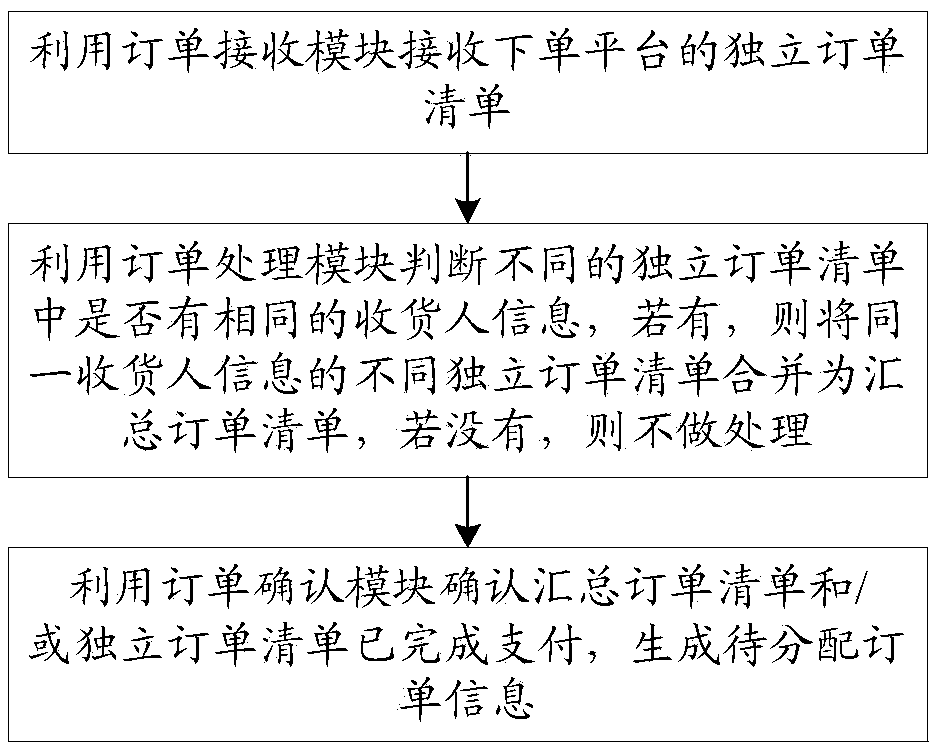

[0066] see figure 1 and figure 2 , a warehouse inventory allocation management system provided in this embodiment, including an order management unit 1, an inventory allocation unit 3, and a picking unit 4 connected in sequence;

[0067] The order management unit 1 is used to generate order information to be distributed;

[0068] The inventory allocation unit 3 is used to generate a commodity outbound list according to the order information to be allocated;

[0069] The picking unit 4 is used to complete the picking in the designated warehouse storage location according to the product delivery list.

[0070] In the warehouse inventory allocation management system provided in this embodiment, it is composed of an order management unit 1, an inventory allocation unit 3 and a picking unit 4 connected in sequence. After the user completes the order operation through the order platform, the order management unit 1 receives The user's order information and generate order informatio

Embodiment 2

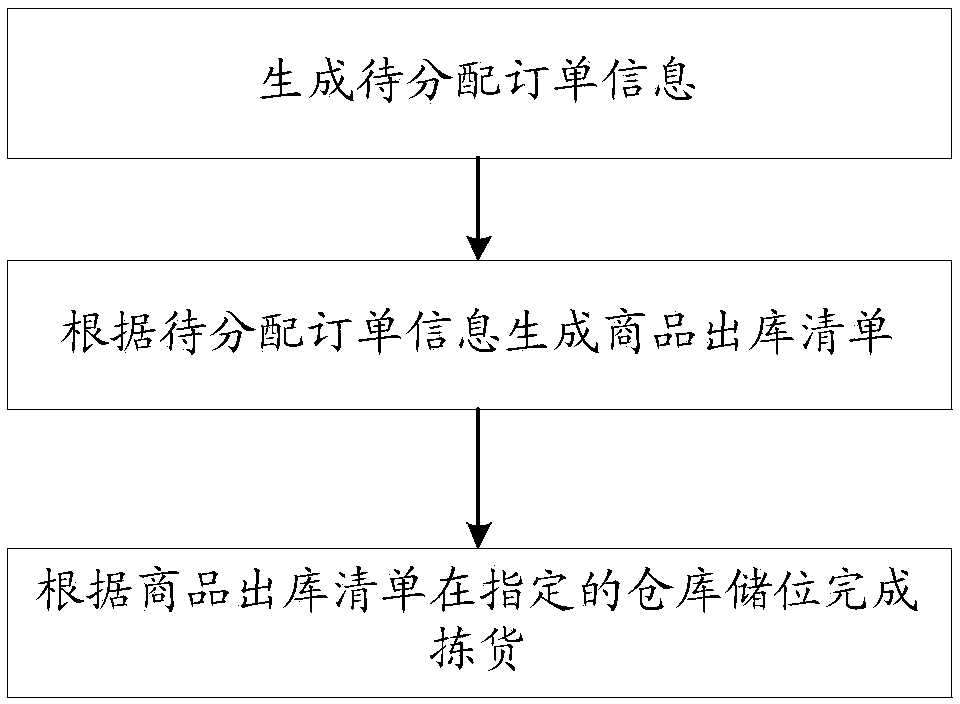

[0086] see figure 2 , the embodiment of the present invention also provides a warehouse inventory allocation management method, including:

[0087] Generate order information to be allocated;

[0088] Generate a commodity outbound list according to the order information to be allocated;

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap