Automotive air conditioner compressor shell structure

A technology for compressor housings and vehicle air conditioners, which is applied to components of pumping devices for elastic fluids, mechanical equipment, machines/engines, etc., can solve problems such as large bottom vibration and loud noise, and reduce vibration. , The effect of reducing noise and reducing compressor noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

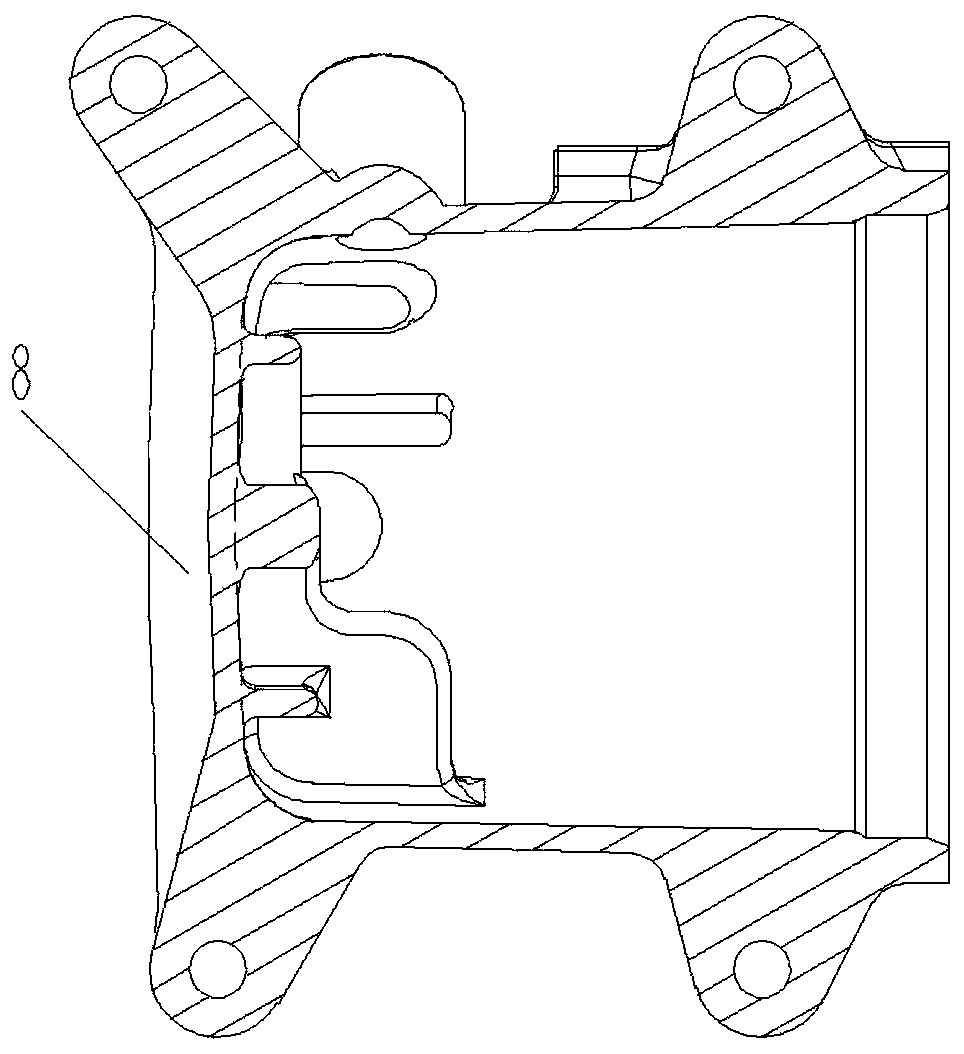

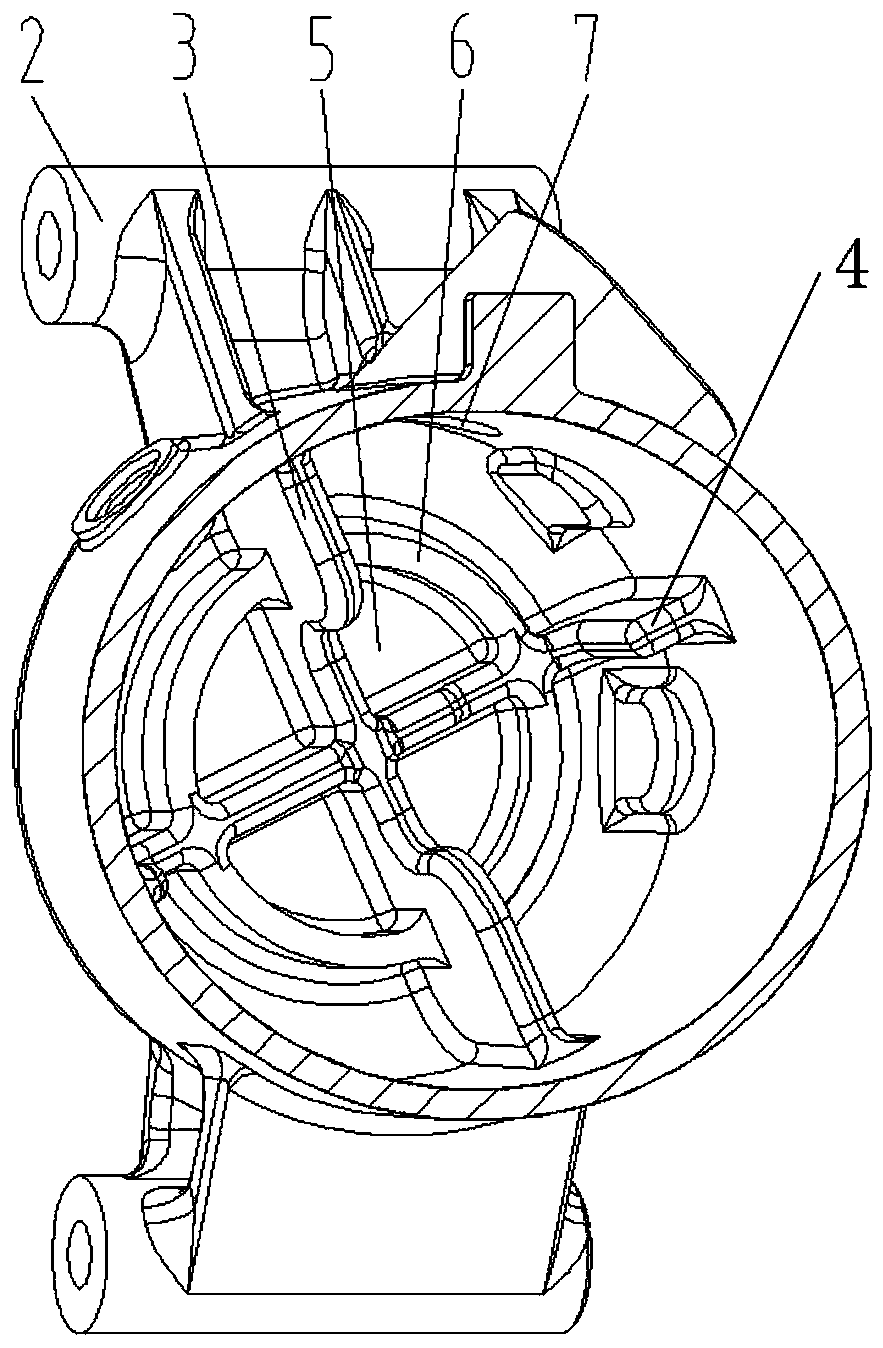

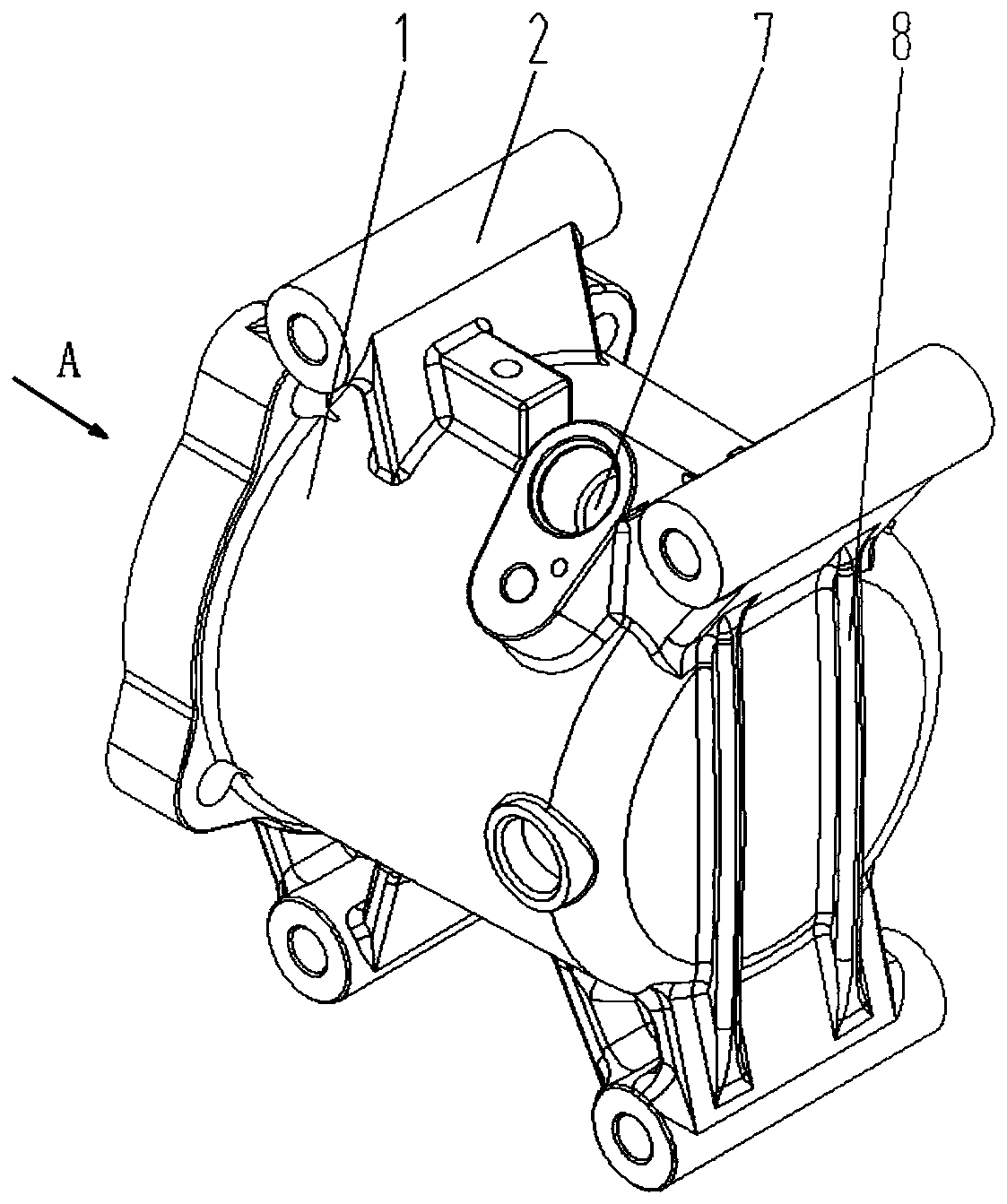

[0020] see Figure 1-Figure 3 , a vehicle air-conditioning compressor shell structure, including a shell body 1, the outer surface of the shell body 1 is provided with a plurality of compressor mounting lugs 2, the inner surface of the bottom of the shell body along the axial direction A first rib 3 and a second rib 4 are extended, and the first rib 3 and the second rib 4 are perpendicular to each other to form a cross partition rib, and the two sides of the first rib 3 and the second rib 4 are respectively It is connected with the inner wall of the housing body 1. In this embodiment, in order to increase the placement space of parts in the housing, the first rib 3 and the second rib 4 adopt concave ribs, and the second rib 4 The concave opening is larger than the concave opening of the first rib 3 to form a space for abdication.

[0021] Betwee

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap