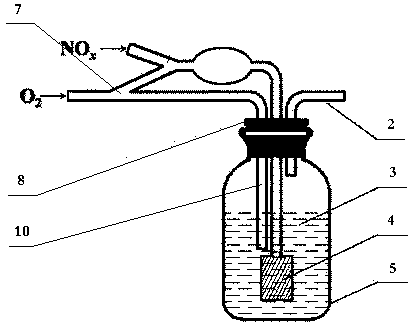

Oxidation absorption system of NOx gas

An oxidation absorption, gas technology, applied in chemical instruments and methods, separation of dispersed particles, separation methods, etc., to achieve the effects of eliminating emissions, protecting the environment, and increasing the degree of oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015]Take 200ml of industrial-grade glyoxal solution (concentration is about 40%), put it into a three-necked flask immersed in a water bath, then add 3ml of concentrated hydrochloric acid to it, and seal each interface of the reaction system with high-temperature vacuum grease. Control the temperature of the water bath to 50°C, turn on the knob, and add the prepared 95.33ml dilute nitric acid solution to the glyoxal solution dropwise. Raise the temperature of the water bath to 63°C, and when brown-red NOx gas appears in the flask, open the decompression valve of the oxygen bottle and inject it into the NOx gas oxidation absorption system connected to the three-necked flask (the absorption liquid is made of H 2 o 2 NaOH solution) and a little excess of oxygen, at this time, it can be observed that the color of the brown-red gas in the three-necked flask rapidly becomes lighter, and the absorption system is covered with a large number of bubbles around the gas distributor in the

Embodiment 2

[0017] Take 20L of industrial grade glyoxal solution, put it into the reaction kettle, then add 300ml of concentrated hydrochloric acid to it, and seal each interface of the reaction system with high-temperature vacuum grease. Control the temperature at 50°C, turn on the knob, and add the prepared 9.5L dilute nitric acid solution to the glyoxal solution dropwise. Raise the temperature to 63°C, and when brown-red NOx gas appears in the reaction kettle, open the pressure reducing valve of the oxygen cylinder and inject it into the NOx gas oxidation absorption system connected to the reaction kettle (absorbing liquid adopts H 2 o 2 NaOH solution) into oxygen and a little excess, at this time the color of the brown-red gas in the reaction kettle becomes lighter rapidly, and a large number of bubbles are covered around the gas distributor 4 in the absorption tank 5 of the absorption system. After a period of time, the absorption tank The color of the internal alkaline absorption liqu

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap