Composite mandrel for fiber pipe weaving

A combination of mandrel and fiber tube technology, applied in the field of fiber tube manufacturing, can solve problems such as difficulty in taking out the mandrel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0027] Embodiments of the combined mandrel for fiber tube braiding provided by the present invention:

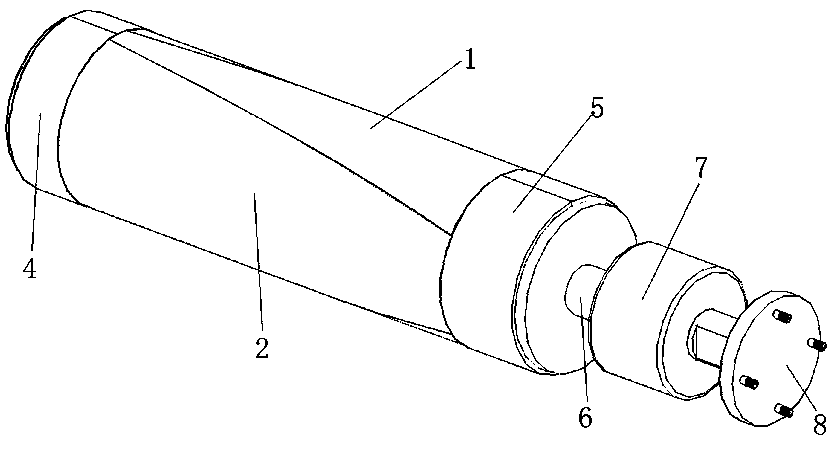

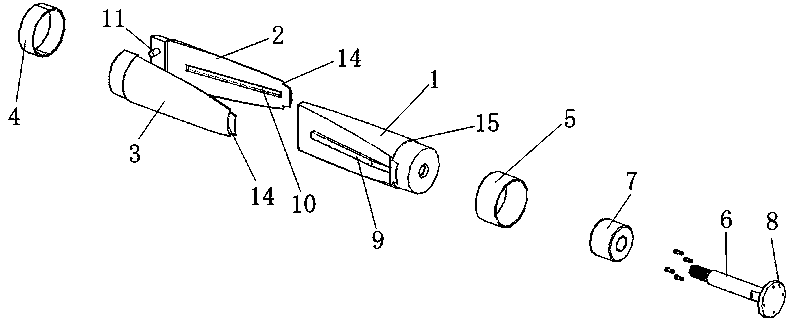

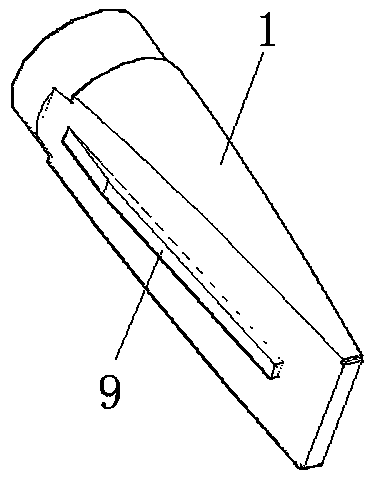

[0028] Such as figure 1 with figure 2 As shown, the combined mandrel for fiber tube braiding includes a first plug-in component 1 and a second plug-in component that are plug-fitted. The first plug-in component 1 extends along the front-to-back direction, and the second plug-in component has a The slot where the plug-in part 1 is inserted. After the first plug-in part 1 is plugged into the second plug-in part, together with the second plug-in part, the formed outer peripheral surface whose axis extends in the front and rear direction is formed. The shaped outer peripheral surface is used for supplying Filament winding and braiding; in this embodiment, the first plug-in component 1 is metal.

[0029] It is defined that the first plug-in co

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap