Acid-resistant powdered oil and preparation method thereof

A powdered grease and oil-based technology, applied in edible oil/fat, food science, application, etc., can solve instability and other problems, and achieve good acid resistance, good milk flavor and taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

preparation example Construction

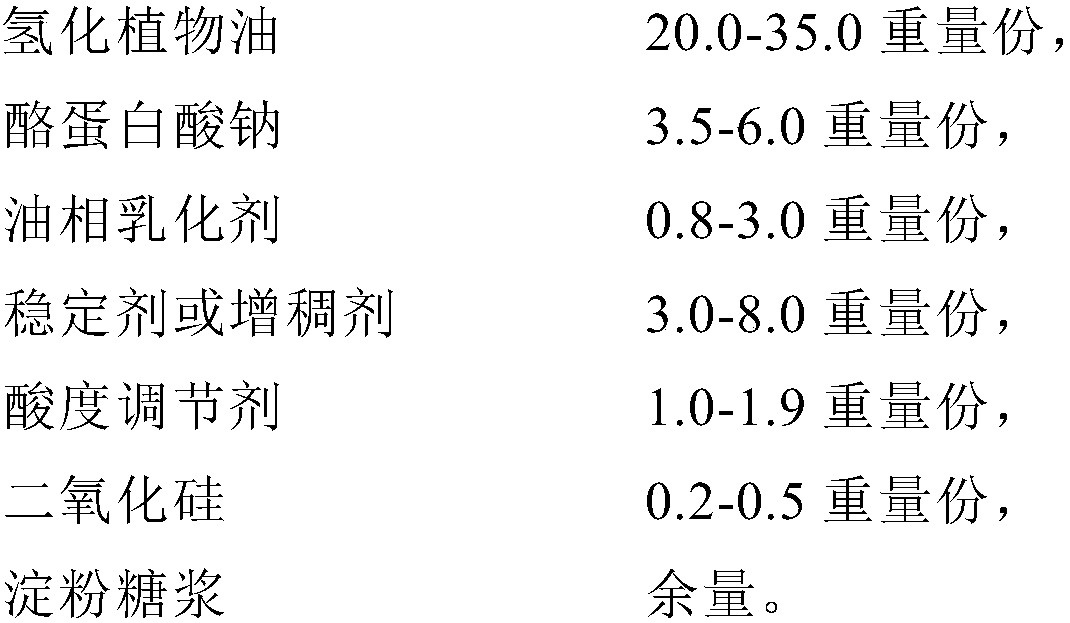

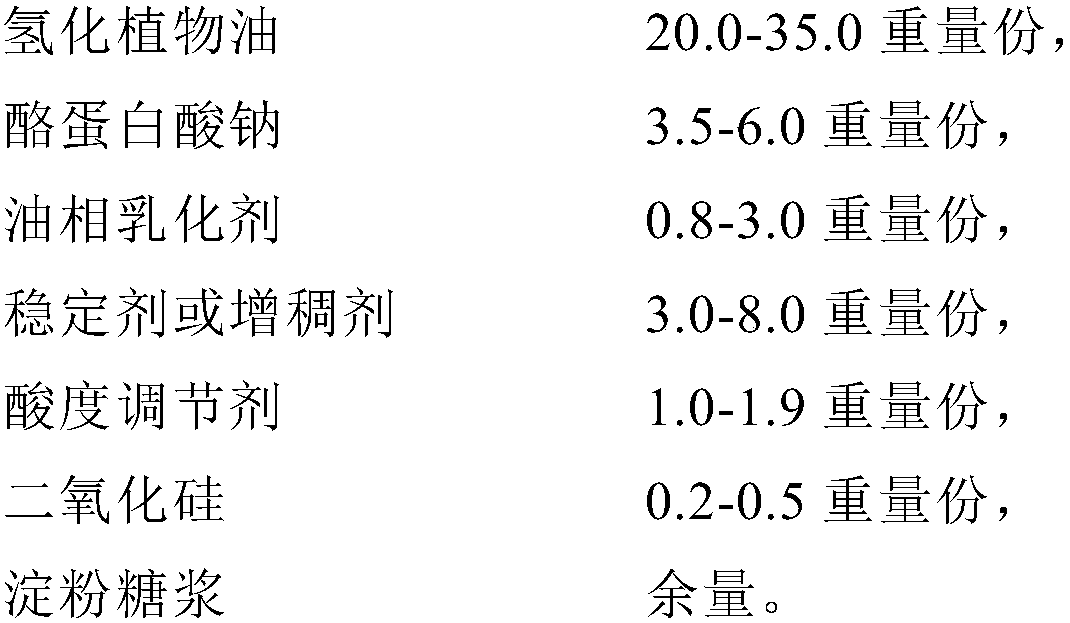

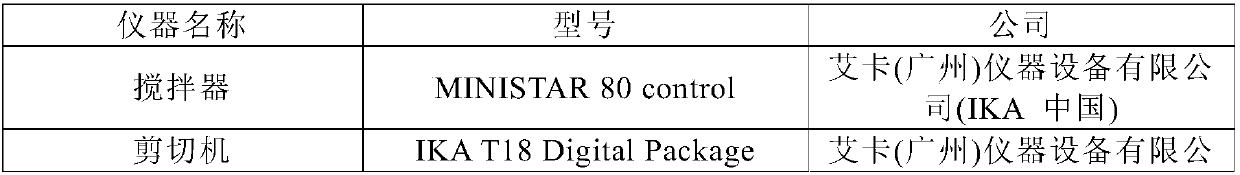

[0063] In another aspect of the present invention, there is also provided a method for making the above-mentioned acid-resistant powdered oil, the preparation method specifically includes the following steps:

[0064] (1) Heating the hydrogenated vegetable oil to 70-80°C, adding an oil phase emulsifier to it, stirring and emulsifying for 15-30 minutes to obtain an oil-based mixture;

[0065] (2) Put starch syrup, soybean polysaccharide, sodium carboxymethyl cellulose, sodium caseinate, dipotassium hydrogen phosphate, and silicon dioxide into water at 65-75°C, stir until completely dissolved, and keep hydrated for 20-30 minutes , to obtain a water-based mixed material liquid;

[0066] (3) Mix the oil-based mixed material liquid obtained in step (1) with the water-based mixed material liquid obtained in step (2), and then shear 15- 30 minutes;

[0067] (4) the feed liquid that step (3) obtains is carried out homogeneous under the pressure of 20-25MPa;

[0068] (5) Spray-dry the

Embodiment 1

[0080] The components of the acid-resistant powder oil product include (100Kg in total): 25Kg of hydrogenated palm kernel oil, 1.4Kg of mono- and diglyceride fatty acid esters, 0.6Kg of diacetyl tartrate mono-diglycerides, 3.5Kg of sodium caseinate, soybean polysaccharide See Table 2 for the addition amount, 0.8Kg of sodium carboxymethyl cellulose, 1.5Kg of dipotassium hydrogen phosphate, 0.3Kg of silicon dioxide, and the balance of starch syrup. Wherein, the polysaccharide content of soybean polysaccharide is ≥ 80wt%. The implementation steps are as follows:

[0081] (1) take each component by the described formula quantity;

[0082] (2) Heating hydrogenated palm kernel oil to 75°C, adding an oil phase emulsifier, stirring and emulsifying for 15 minutes to obtain an oil-based mixture;

[0083] (3) Put starch syrup, soybean polysaccharide, sodium carboxymethyl cellulose, sodium caseinate, dipotassium hydrogen phosphate, and silicon dioxide into water at 65°C, stir until complet

Embodiment 2

[0092] The components of the acid-resistant powder oil product include (100Kg in total): 28Kg of hydrogenated soybean oil, 1.5Kg of mono- and diglyceride fatty acid esters, 0.5Kg of diacetyl tartrate mono- and diglycerides, 4.0Kg of sodium caseinate, pectin added The amount is shown in Table 3, sodium carboxymethylcellulose 0.8Kg, dipotassium hydrogen phosphate 1.5Kg, silicon dioxide 0.3Kg, and the balance of starch syrup.

[0093] The implementation steps are as follows:

[0094] (1) take each component by the described formula quantity;

[0095] (2) Heating hydrogenated soybean oil to 80°C, adding an oil phase emulsifier, stirring and emulsifying for 30 minutes to obtain an oil-based mixture;

[0096] (3) Put starch syrup, pectin, sodium carboxymethyl cellulose, sodium caseinate, dipotassium hydrogen phosphate, and silicon dioxide into water at 75°C, stir until completely dissolved, and keep hydrated for 30 minutes to obtain a water-based mixed liquid;

[0097] (4) After mix

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap