Method for extracting CO and H2 from raw gas

A raw gas and purified gas technology, applied in the chemical industry, can solve problems such as increased operating costs and equipment, ineffective use of heat, and high energy consumption for hydrogen recovery, achieving low equipment investment and operating costs, high reliability, and improved efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

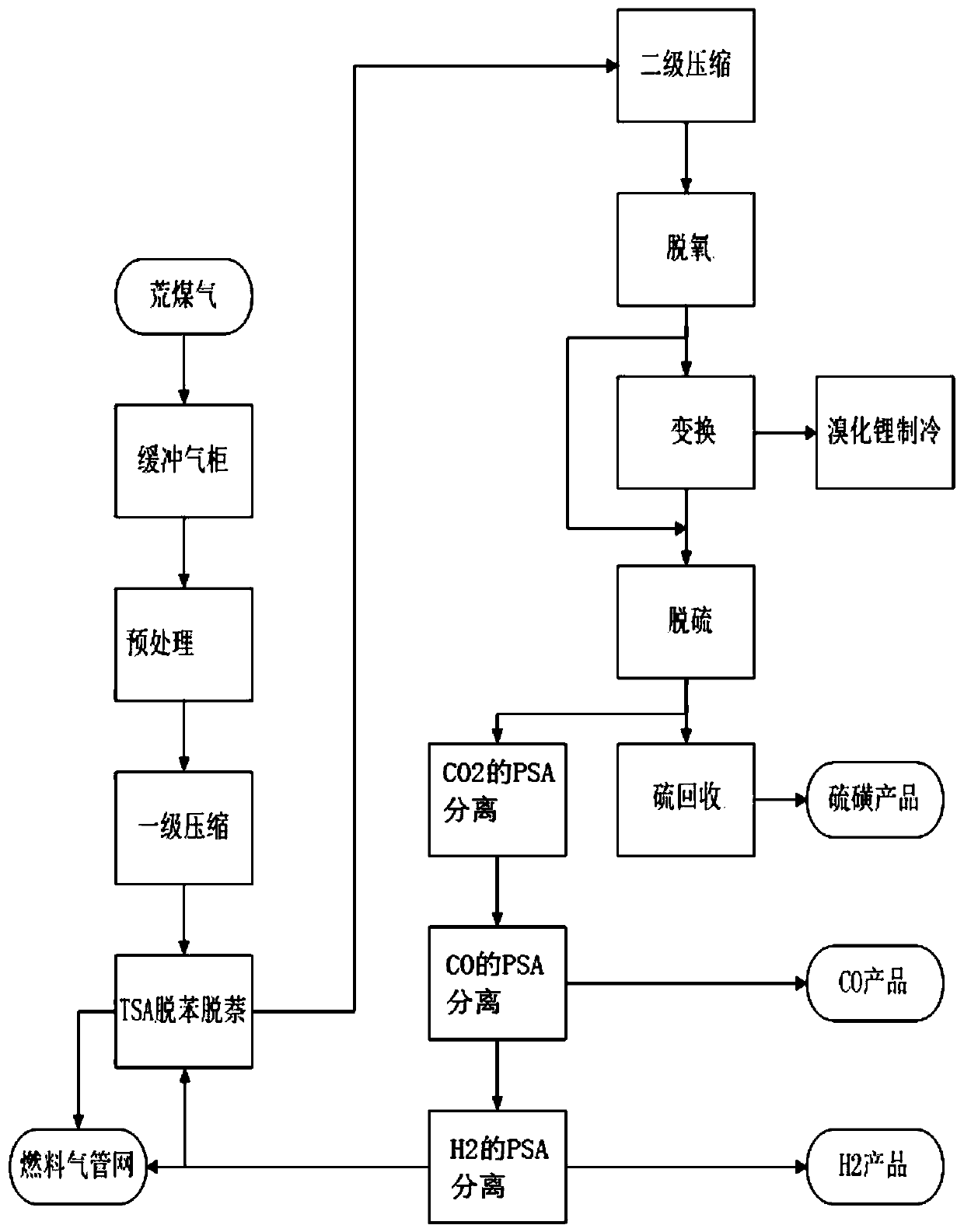

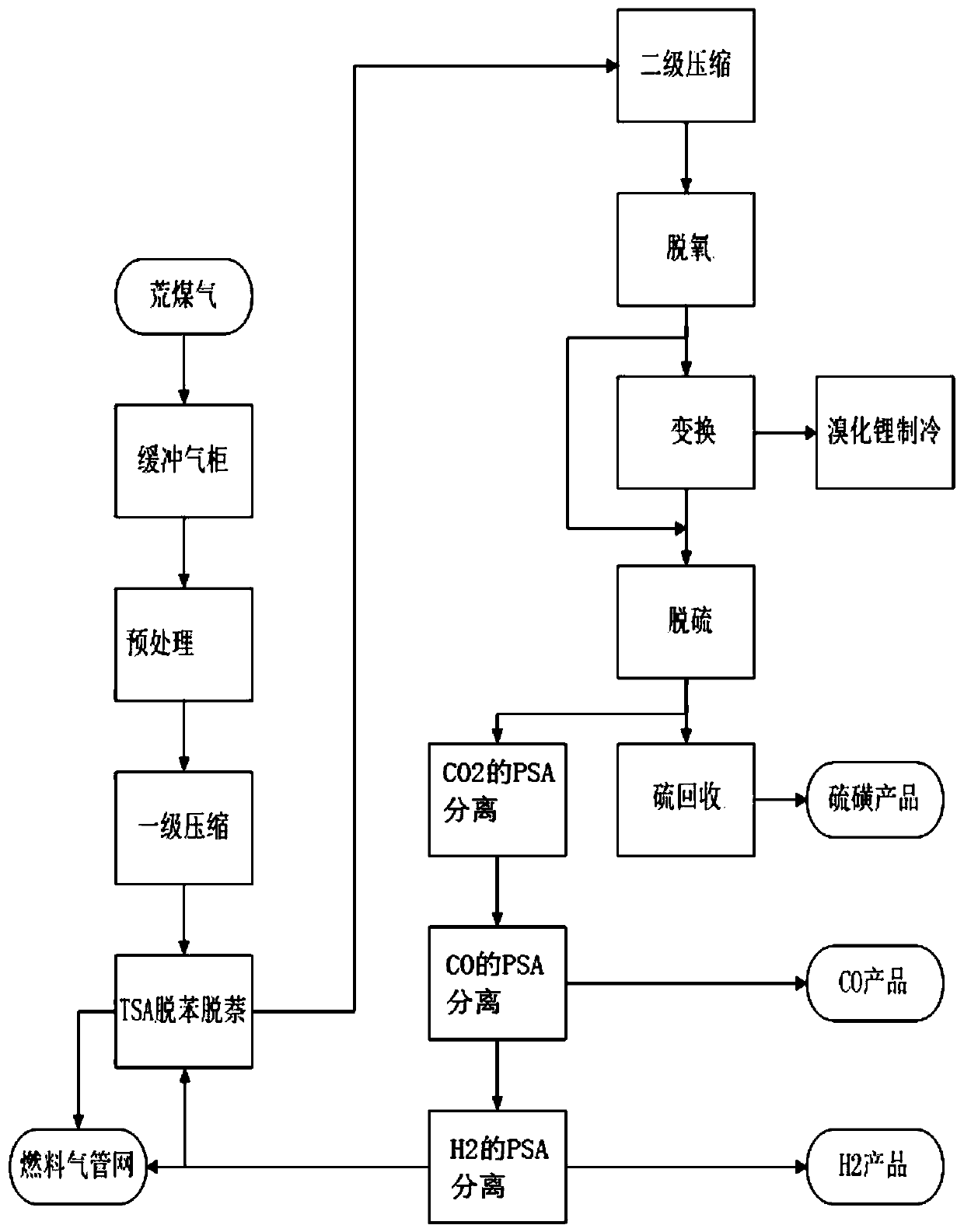

[0016] The present invention will be further explained below in conjunction with the drawings:

[0017] See figure 1 , A process for extracting CO and H2 from raw gas, including the following steps:

[0018] (1) The raw gas is pre-treated after passing through the buffer gas tank: the tar in the raw gas is removed by the electric flutter, and the concentration of the tar in the raw gas after treatment is lower than 1mg / Nm3, and the raw gas after pretreatment is obtained;

[0019] (2) One-stage compression: the raw gas after the pretreatment is compressed in one stage to obtain the compressed raw gas, and the outlet pressure of the first-stage compression is 0.3MPa(G);

[0020] (3) TSA removal of benzene and naphthalene: After pressurization, the raw gas is cooled by heat exchange with low-temperature water and the temperature is reduced to 15-20 ℃, and then TSA is debenzene and naphthalene removed to obtain raw gas after benzene and naphthalene removal. The TSA operating pressure is 0.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap