Automatic shifting device

An automatic and rack-mounted technology, applied in the direction of transportation and packaging, conveyor objects, etc., can solve the problems of increasing equipment costs and labor costs, and achieve the effects of low cost, simple structure, and simple requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

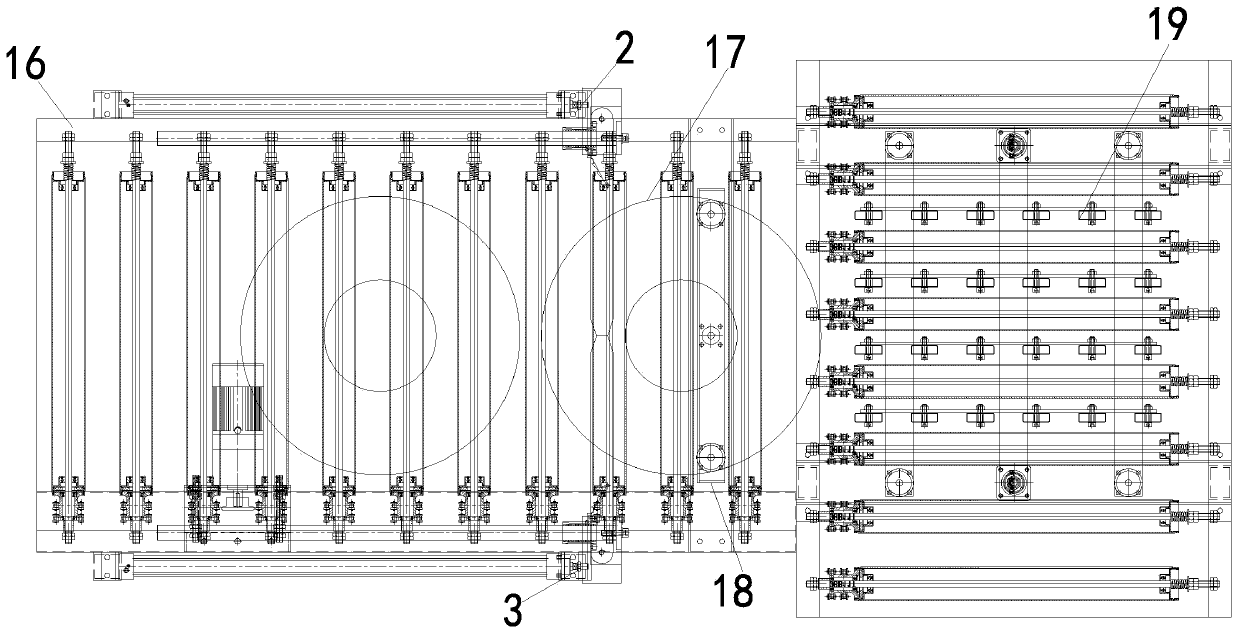

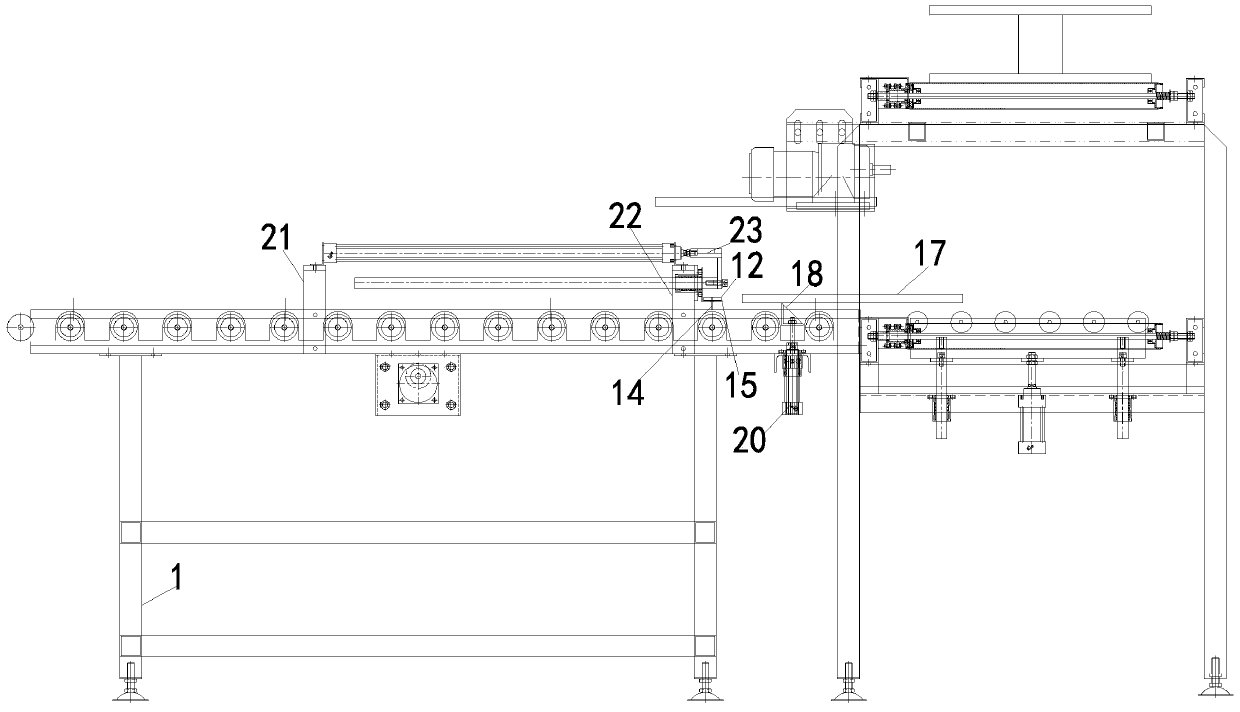

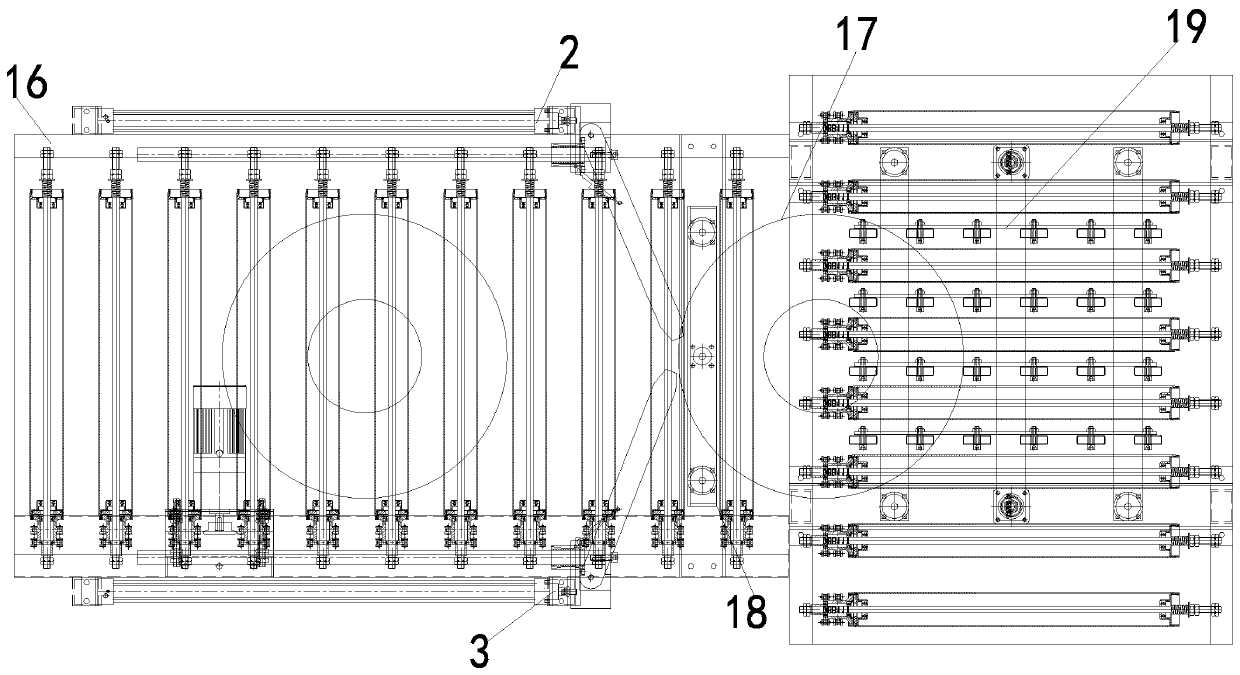

[0019] attached Figure 1-5 The automatic shifting device of the present invention includes a frame 1; the frame 1 is provided with a conveying line 16; the conveying line 16 is horizontally arranged on the same plane by conveying rollers (not shown); the The conveying roller is driven by a motor (not shown) to rotate on its own; one side of the frame 1 is provided with a first bracket 21 and a second bracket 22; the first bracket 21 and the second bracket 22 are provided with a first paddle Device 3; the first paddle device 3 includes a first electric cylinder 10, a first slide bar 11, a first paddle 12, a first return spring 13, a first rotating s

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap