Double-carrier exposure machine

An exposure machine and dual-stage technology, which is used in optomechanical equipment, microlithography exposure equipment, optics, etc., can solve the problems of slow transmission efficiency of photosensitive substrates and low production rate of exposure machines, so as to improve production speed and transmission. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0046] The dual stage exposure machine according to the embodiment of the present invention will be further described below in conjunction with the accompanying drawings.

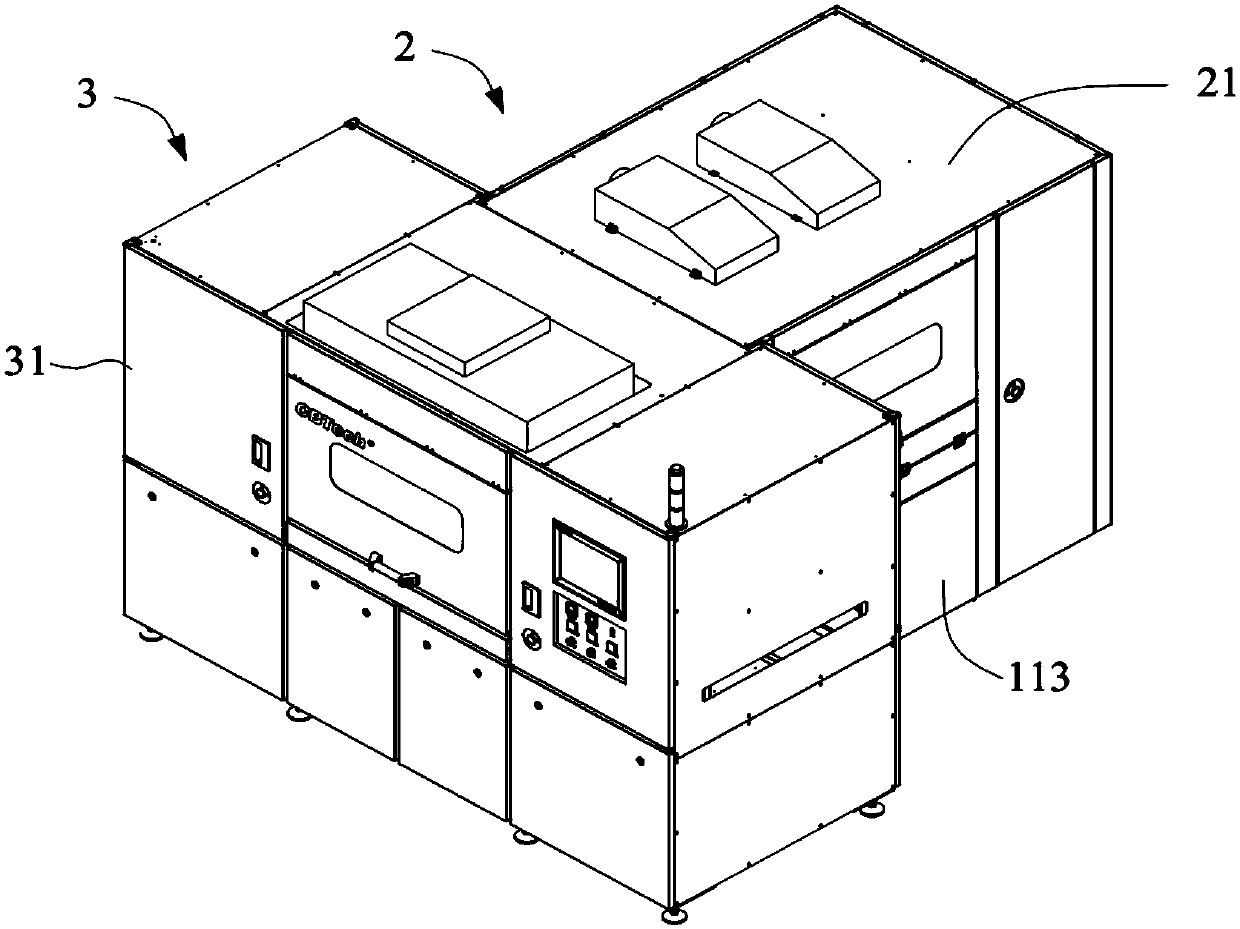

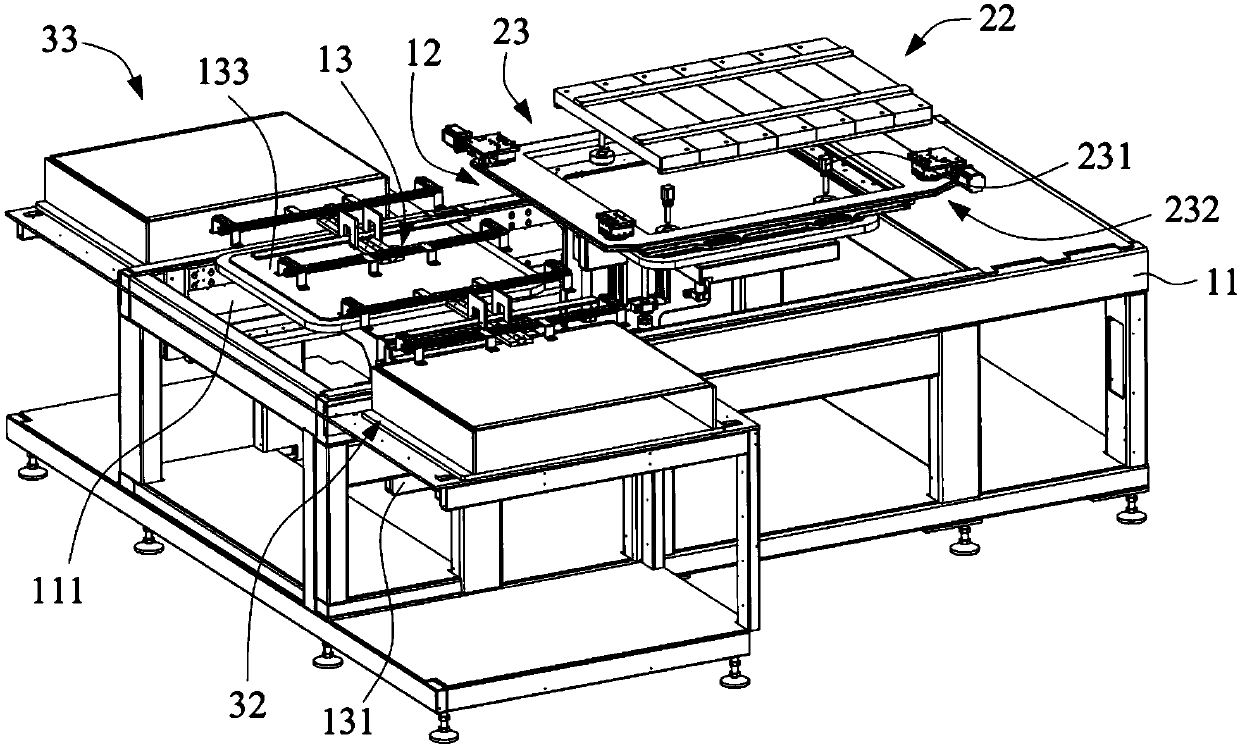

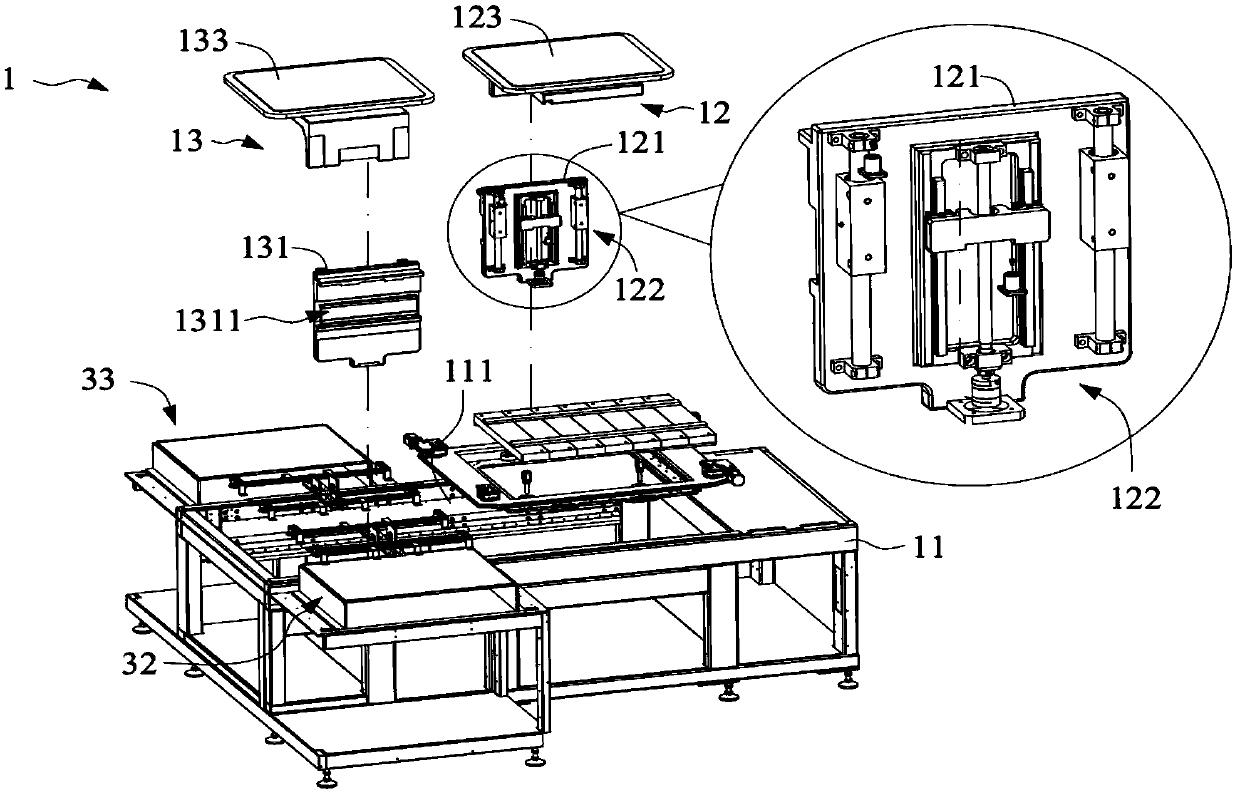

[0047] See Figure 1 to Figure 4 , As shown in the figure: a dual-stage exposure machine of the present invention includes a conveying device 1, a light source generating device 2 and a feeding device 3.

[0048] The conveying device 1 includes a base 11, a first conveying mechanism 12, and a second conveying mechanism 13. The inner sides of the base 11 are respectively provided with a first driving unit 111 and a second driving unit 112 facing each other. The first conveying mechanism 12 has a first base 121, a first lifting unit 122, and a first carrying unit 123. The first base 121 is disposed on the first driving unit 111, and the first lifting unit 122 is disposed. On one side of the first base 121, the first carrying unit 123 is provided on the first lifting unit 122, and the second conveying mechanism 13 ha

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap