Needle pre-filling continuous production process for plastic medicine bottles

A production process and medicine bottle technology, which can be used in household components, household appliances, other household appliances, etc., can solve problems such as pollution, and achieve the effects of solving pollution problems, product sterility and safety, and increasing functions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with embodiment:

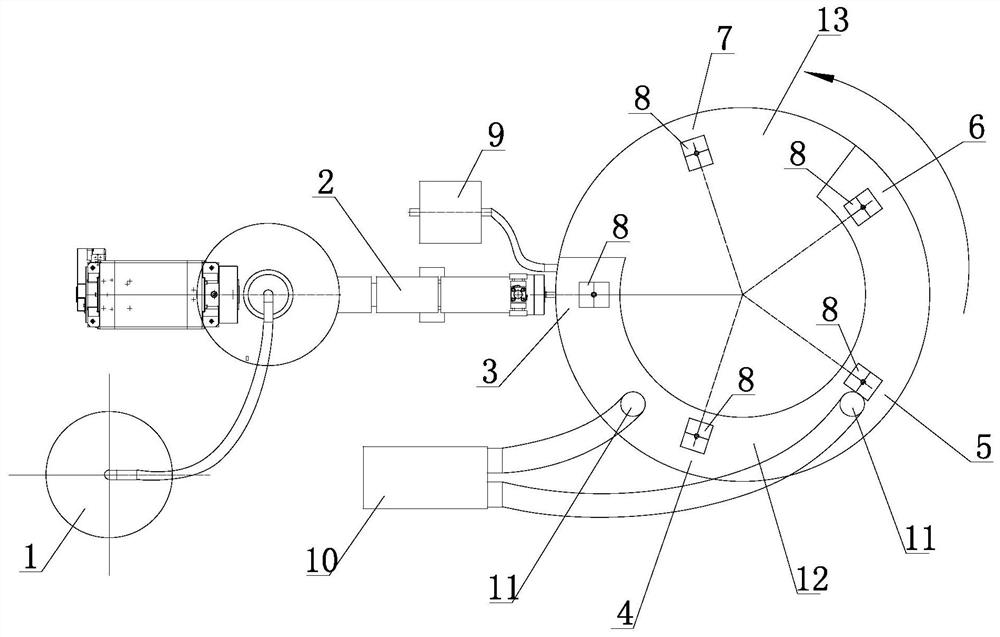

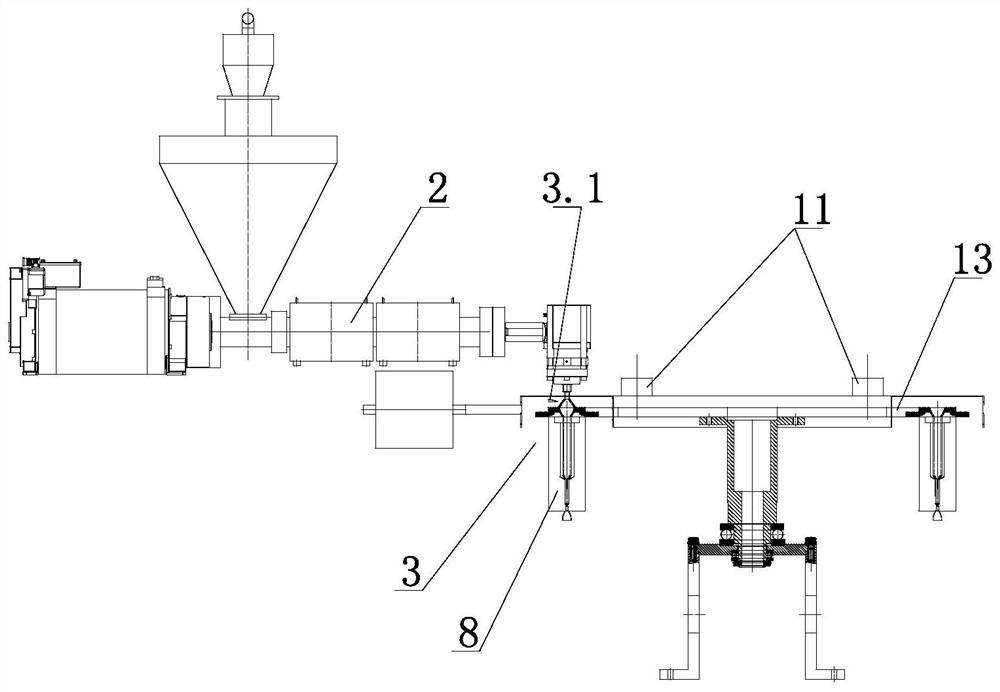

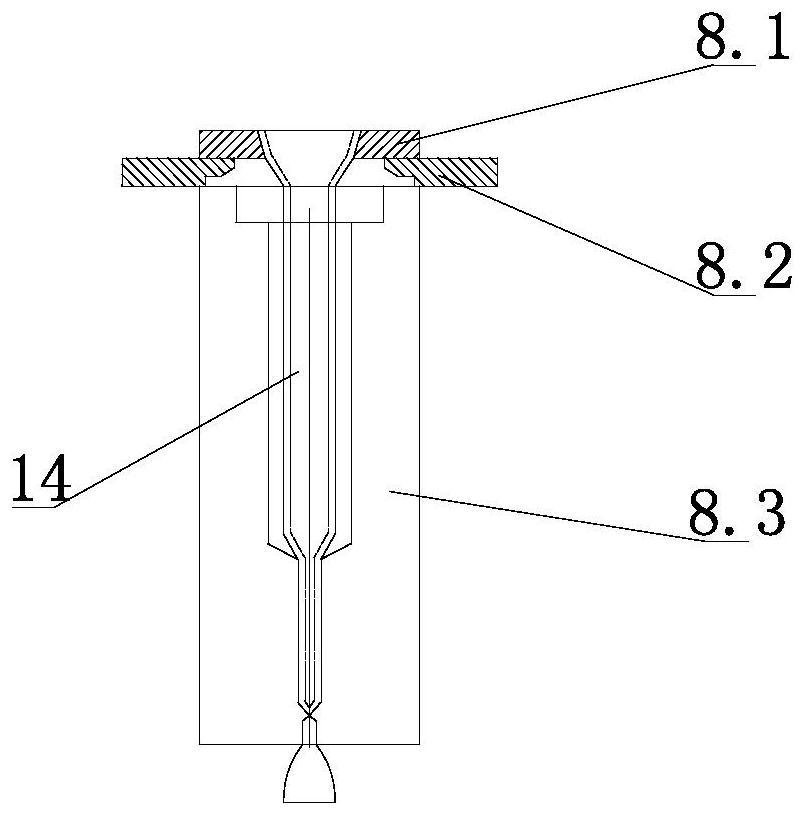

[0038] Such as Figure 1-12 Shown, the plastic medicine bottle prefilling needle continuous production technique of the present invention comprises the following steps:

[0039] ①Tube embryo extrusion: Extruder 2 carries out vacuum feeding through vacuum feeder 1, and the plastic particles are transported from the plastic particle temporary storage room to the plastic particle hopper of extruder 2 through the action of vacuum; extruder 2 It is mainly composed of plastic granule hopper, extruder driving mechanism (driven by hydraulic motor, variable frequency motor, servo motor or constant torque motor, etc.), extruder screw, heating system, water cooling system, pressure detection system, die head system, and corresponding The wall thickness control system consists of the extruder 2 heating and melting the plastic particles, driven by the extruder drive mechanism and the plasticizat...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap