Method for calculating resistance of SCR denitration catalyst

A denitrification catalyst and resistance calculation technology, which is applied in the field of numerical simulation combining macroscopic and mesoscopic, catalyst resistance calculation, can solve the problems of large amount of calculation, large calculation error, low calculation efficiency, etc., and achieve high accuracy, network The effect of reducing the number of grids and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

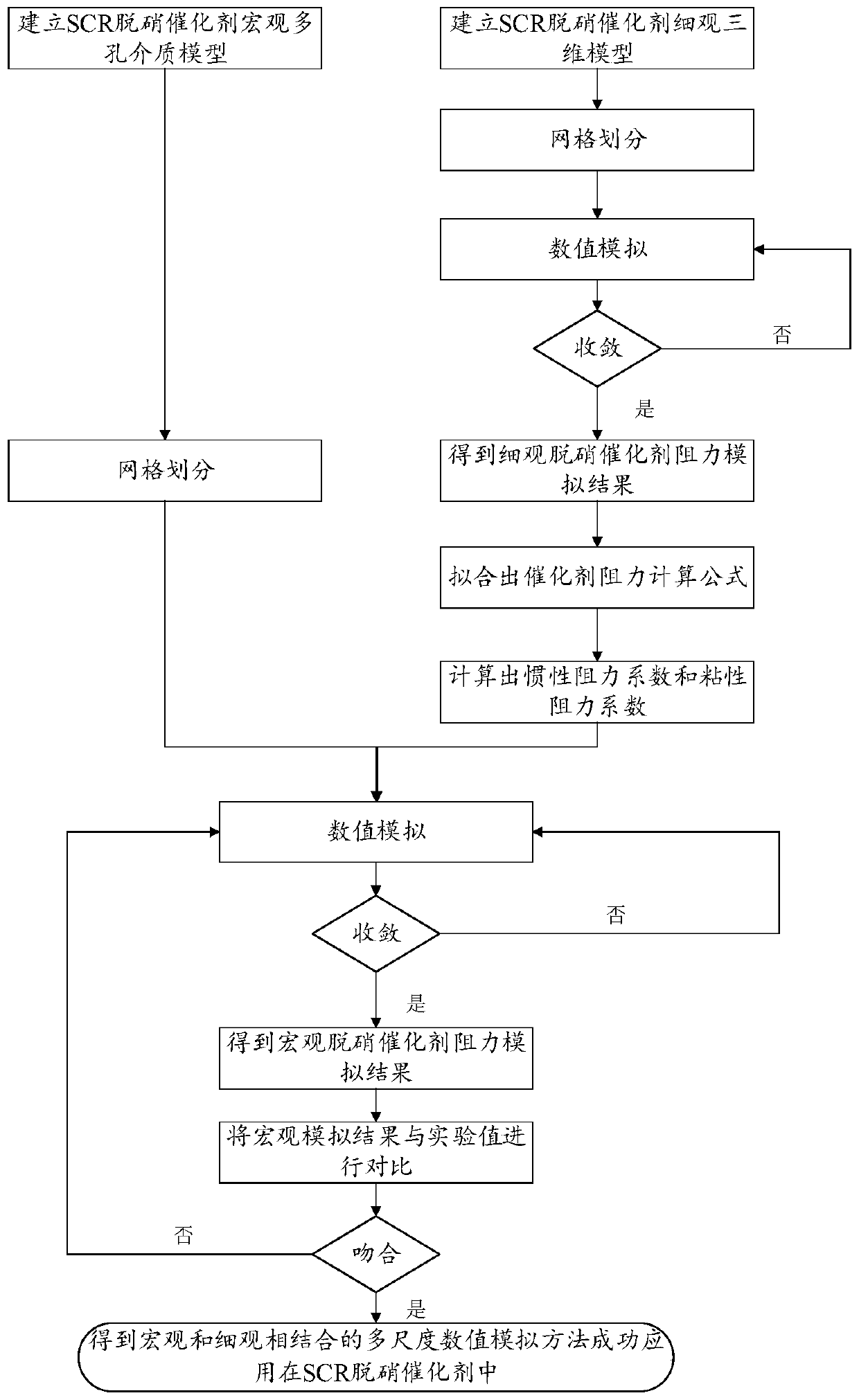

[0043] Taking the SCR denitrification system of a large coking plant as an example, the internal equipment of the SCR denitrification system is relatively complex, and the uniformity of the airflow distribution is difficult to predict. As the catalyst is an important part of the denitrification system, it is particularly important to accurately measure the resistance change caused by the catalyst layer. combine figure 1 , a resistance calculation method of an SCR denitration catalyst in this embodiment, based on CFD software, conducts multi-scale numerical simulation combining macroscopic and mesoscopic aspects of the SCR denitration catalyst to calculate the resistance change caused by fluid passing through the catalyst layer. The resistance calculation method comprises the following steps:

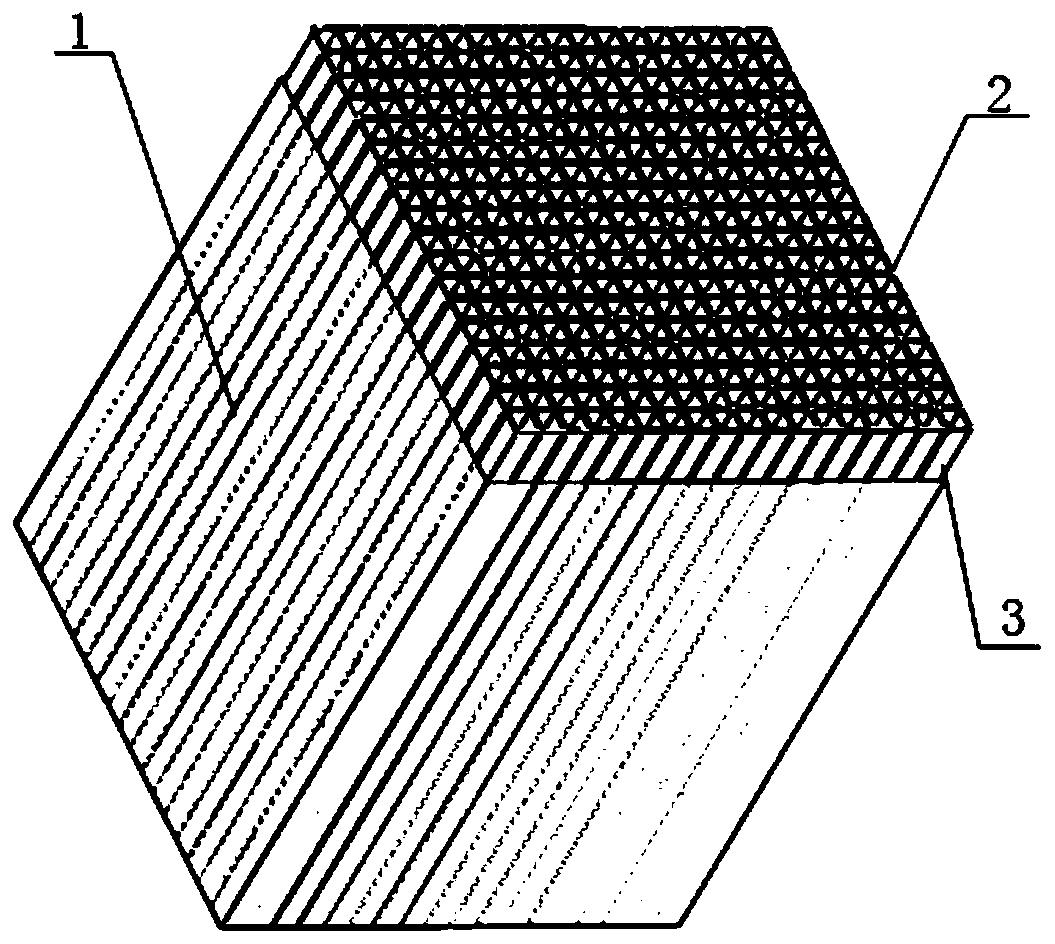

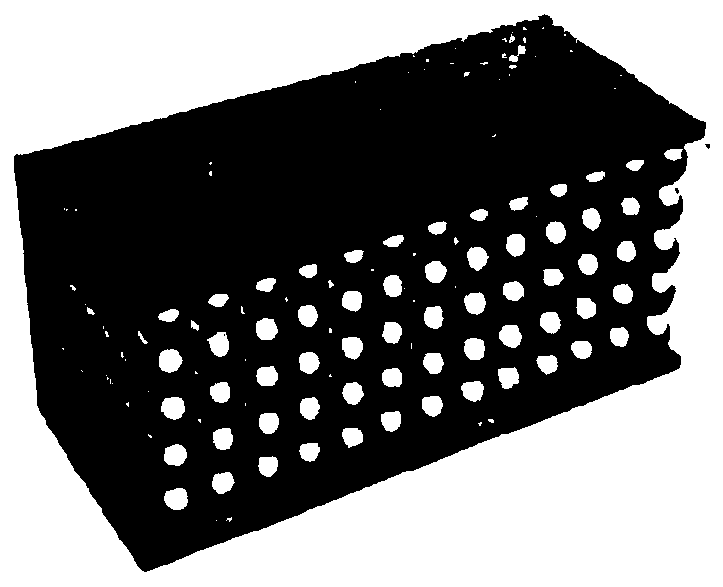

[0044] Step 1: Establish a mesoscopic three-dimensional geometric model of the SCR denitration catalyst, in which specific parameters such as catalyst height, width, number of openings, and

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap