Feed additive with coated sodium humate and preparation method and processing apparatus thereof

A technology of feed additive and sodium humate, which is applied in the forming or processing of animal feed, feed, animal feed, etc., can solve the problems affecting the digestion and absorption of other substances, affecting the appearance and palatability of products, and achieve high processing efficiency and high production efficiency. Convenience, effect of reducing diarrhea rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

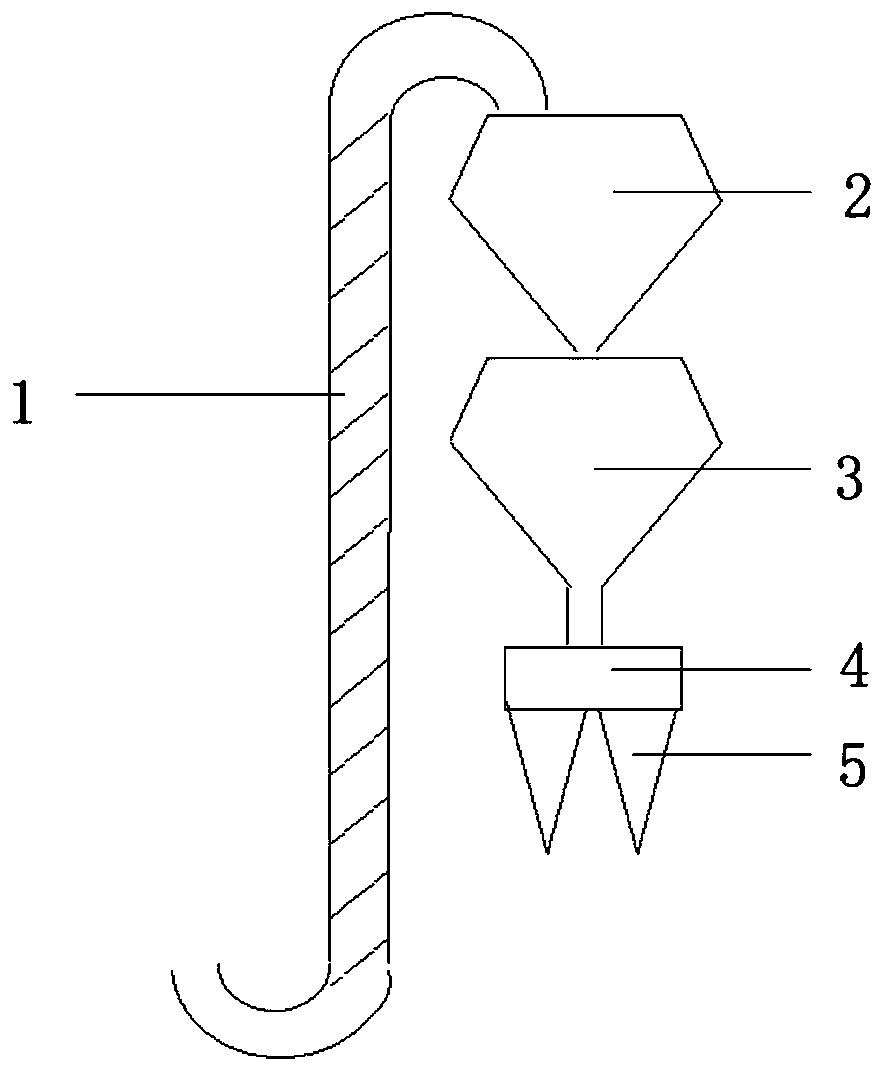

Image

Examples

Embodiment 1

[0025] This embodiment provides a feed additive containing coated sodium humate, said feed additive comprising the following components calculated in parts by weight: 90 parts of sodium humate, 5 parts of 52-degree palm oil and 5 parts of montmorillonite .

[0026] Preferably, the sodium humate is feed grade sodium humate, and the sodium humate content in the feed additive is ≥65%, and the water content is ≤12%.

[0027] Preferably, the sodium humate is a particle with a diameter of 1-1.7mm.

[0028] Preferably, the montmorillonite is feed grade montmorillonite, and the particle size of the montmorillonite is above 200 mesh.

Embodiment 2

[0030] This embodiment provides a feed additive containing coated sodium humate, said feed additive comprising the following components calculated in parts by weight: 85 parts of sodium humate, 2 parts of 52-degree palm oil, and 2 parts of montmorillonite .

Embodiment 3

[0032] This embodiment provides a feed additive containing coated sodium humate, said feed additive comprising the following components calculated in parts by weight: 95 parts of sodium humate, 8 parts of 52-degree palm oil, and 8 parts of montmorillonite .

[0033] The appearance of the sodium humate provided by Examples 1-3 is gray-white uniform particles, and adding it to the feed has no effect on the appearance of the feed product; the montmorillonite wrapped in the outer layer can play the role of adsorbing mycotoxins; palm oil guarantees the sodium humate Avoid contact with gastric acid in the stomach, decompose and release in the intestinal tract, do not affect the function of sodium humate, and at the same time provide the lipids needed for animal growth.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap