Online switching method of single-nozzle overhead entrained-flow pulverized coal gasifier

A gasification furnace, top-mounted technology, applied to the gasification of granular/powdered fuels, gasification device details, and the manufacture of combustible gases, etc., can solve the problems of long time and the impact of syngas on economic benefits, etc. Reduce economic losses and maintain stable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing:

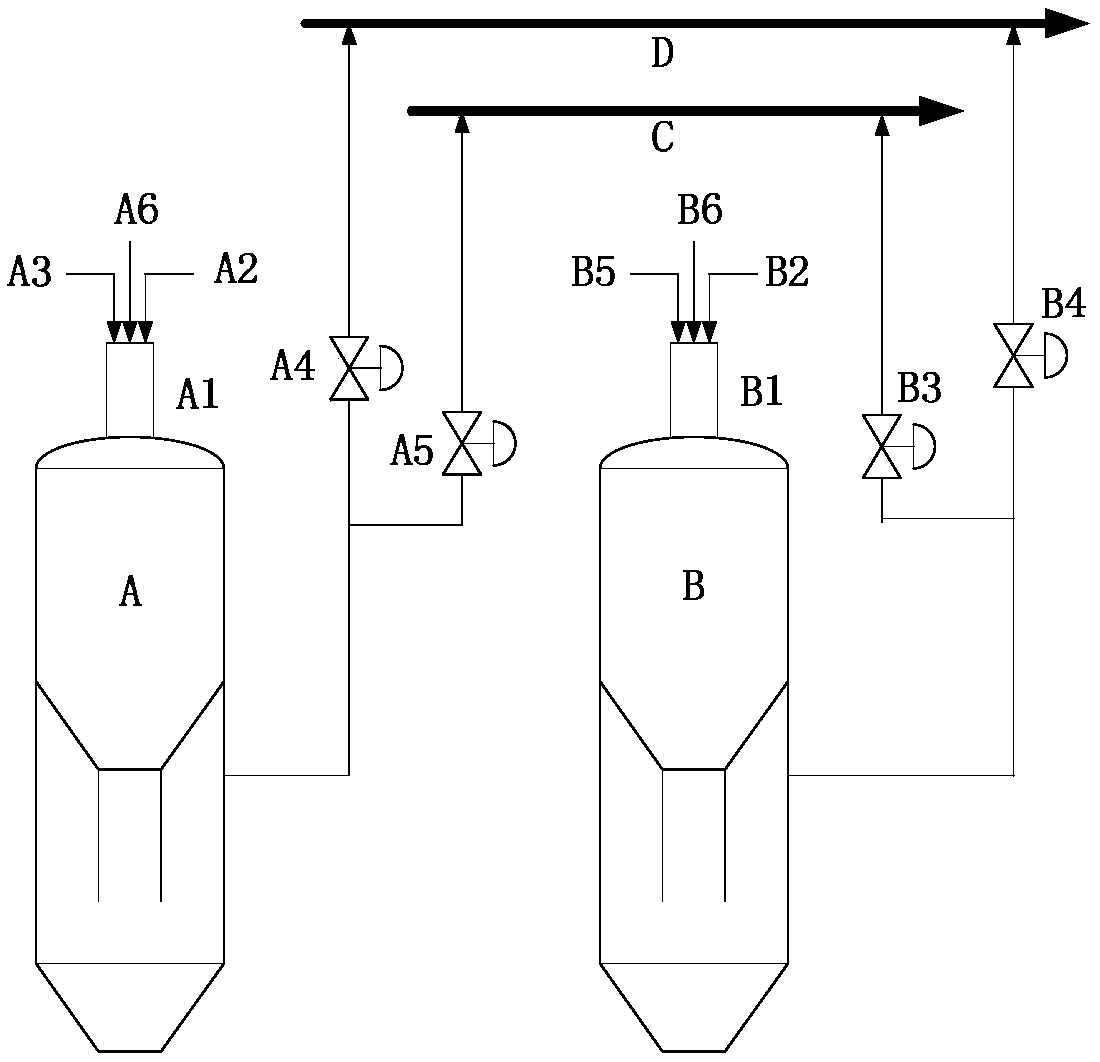

[0016] refer to figure 1 The shown equipment part of the present invention includes a first gasifier A and a second gasifier B, each of which is provided with a nozzle A1, B1 at the top.

[0017] In this embodiment, three pulverized coal inlets are set on the nozzle A1 of the first gasifier A, respectively connected to three pulverized coal pneumatic conveying pipelines A2, A3, A6, and the nozzle B1 of the corresponding second gasifier B is also set. Three pulverized coal inlets are respectively connected to three pulverized coal pneumatic conveying pipelines B2, B5 and B6. The pulverized coal that enters the first gasifier A or the second gasifier B through the nozzle is a dry powder that meets the pneumatic conveying conditions.

[0018] The synthesis gas outlet of the first gasifier A is connected to the flare vent main pipe C and the synthesis gas system main pipe D thro

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap