Double-layer lapping-hole-free paper tube composite filter tip and forming equipment

A technology of composite molding and filter rods, which is applied in the field of tobacco filter rods, can solve problems such as unsatisfactory cooling effect, low release of harmful components, unstable circumference of paper empty tubes, and unstable roundness, etc., to achieve good supportability and Cooling effect, lower production cost, good supporting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

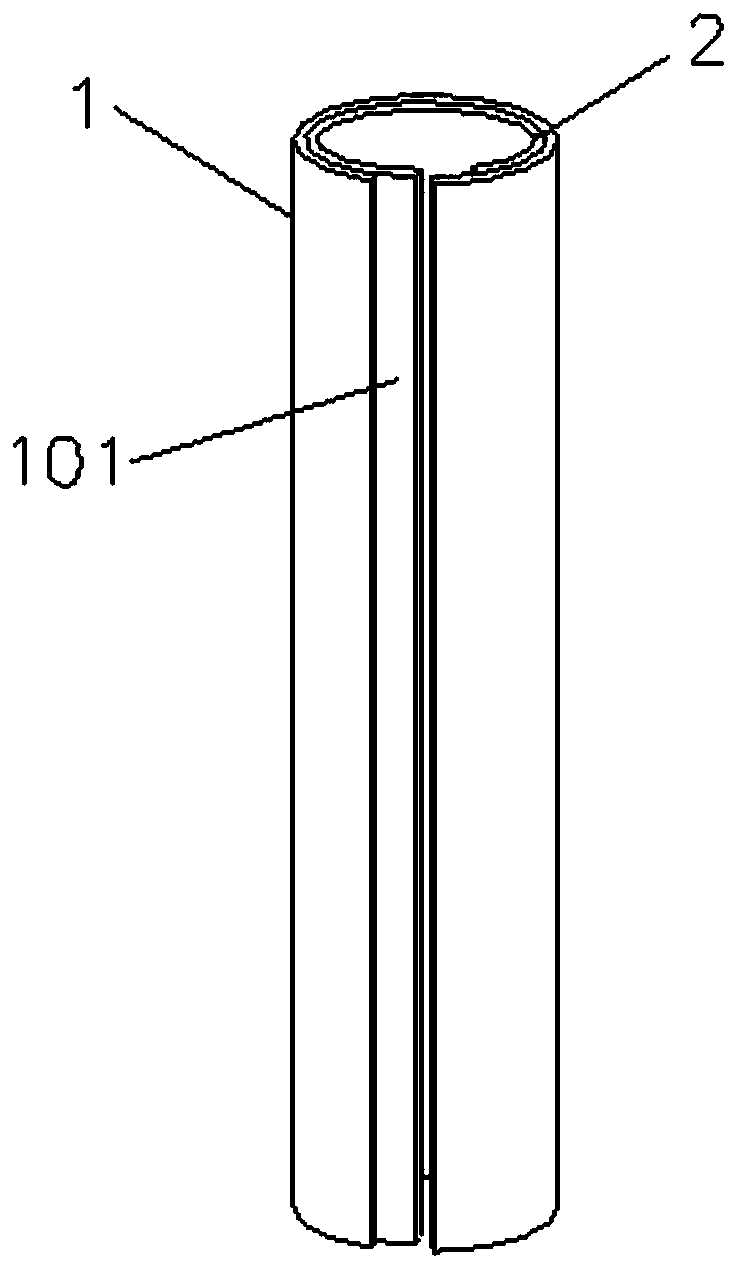

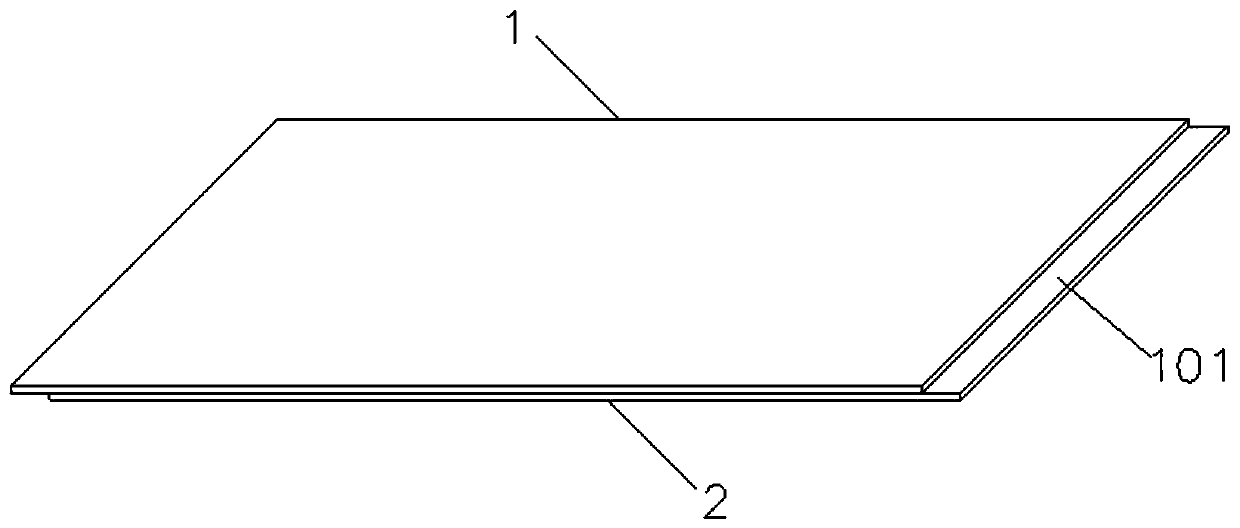

[0035] Such as Figure 1-2 shown

[0036] A double-layer non-lapping paper tube rod, including the first forming paper 1 and the second forming paper 2 of the same specification, the short sides of the first forming paper 1 and the second forming paper 2 are aligned and overlapped, and the long sides of the forming paper at the outer end are The end shrinks back to form a lap 101, and the lap is butted by a paper tube forming device to form a smooth transition, and the ends of the first forming paper 1, the second forming paper 2 and the lap 101 are bonded by vinyl acetate latex;

[0037] In the solution of the present invention, the paper tube stick formed by the first molding paper 1 and the second molding paper 2, through the double-layer molding paper and the design of the shrink-back molding seam, skillfully transitions the seam position smoothly, and at the same time has a relatively Good support, better than single-layer molded paper and spiral-formed paper tube;

[0038

Embodiment 2

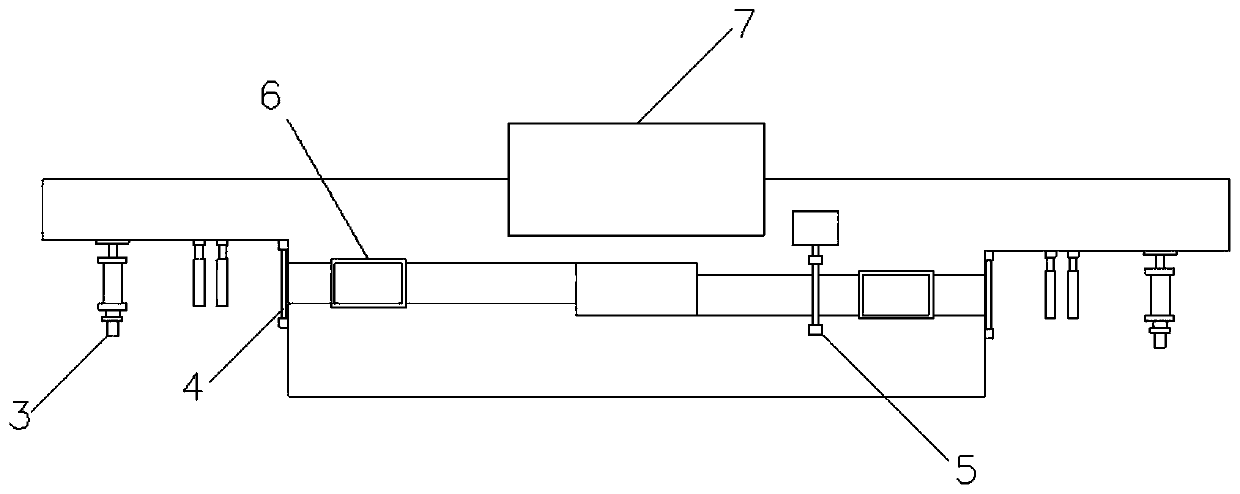

[0041] Such as Figure 1-6 shown

[0042]The paper tube forming device includes an unwinding mechanism 3, a shearing mechanism 4, a gluing device 5, a feeding mechanism 6, an overlapping forming mechanism 8 and a pipe cutting mechanism. The unwinding mechanism 3 is located on the left and right sides, and the two unwinding mechanisms 3 There is a displacement difference in the horizontal and vertical directions. The end of the unwinding mechanism 3 is a feeding mechanism 6 and a shearing mechanism 4 is installed. The unwinding mechanism 3 at one end is equipped with a gluing device 5, which is installed in the middle of the two unwinding mechanisms 3. The lap forming mechanism 8, the lap forming mechanism 8 overlaps the first forming paper 1 and the second forming paper 2 to form a double-layer paper tube, and at the same time, a pipe cutting mechanism is installed on the lap forming mechanism 8 to cut off the two ends of the paper tube and Cut evenly.

[0043] The unwinding me

Embodiment 3

[0063] A filter rod compositely formed by a double-layer non-lapping paper tube rod;

[0064] The composite molded filter rod is formed by rolling up the tobacco-connecting section, the paper tube rod section and the mouth section through the filter rod forming paper, and the tobacco-connecting section is formed by compacting shredded tobacco or flakes and then connecting the paper tube rod section , the inner wall and outer wall of the paper tube rod are sprayed with cooling material, and the rear end is connected with the mouth section of acetate fiber or polylactic acid fiber, which is integrally formed by wrapping filter rod molding paper.

[0065] The filter rods compounded with double-layer non-lapping paper tube rods include thin filter rods and thick filter rods;

[0066] The length of the paper tube stick section exceeds the single length of the cigarette receiving section and the mouth holding section, but does not exceed the sum of the two.

[0067] Apply the paper tu

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap