Tool for closing in plunger assembly and machining method

An assembly and column alignment technology, which is applied in the field of tooling and processing for closing the plunger assembly, can solve the problems of permanent damage to the assembly, fluctuations in the product qualification rate, and dependence on the processing qualification rate, and achieves good consistency and flexible closing deformation. Control and avoid the effect of cutting edge effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to better illustrate the present invention, it will be described in detail below in conjunction with the accompanying drawings.

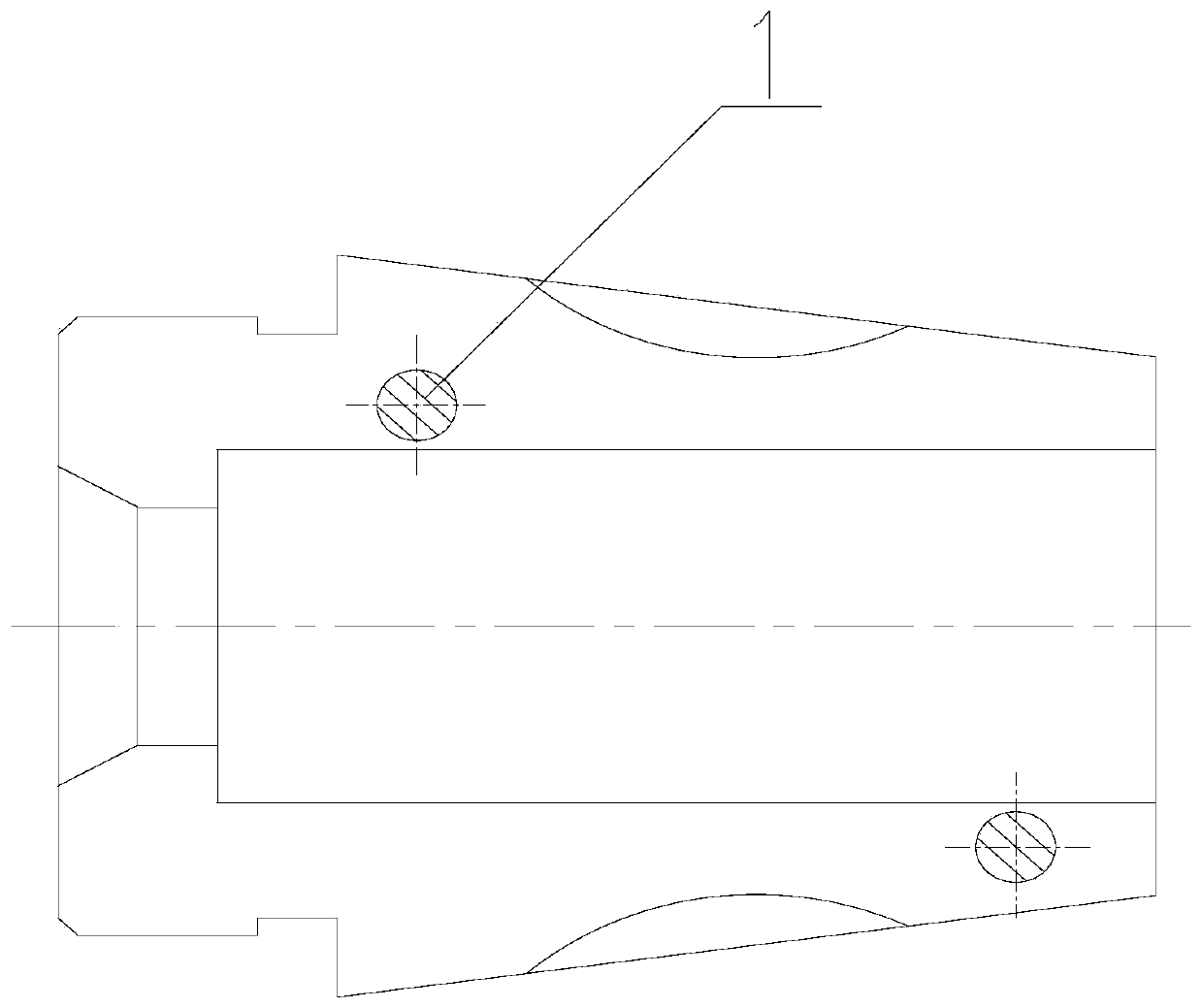

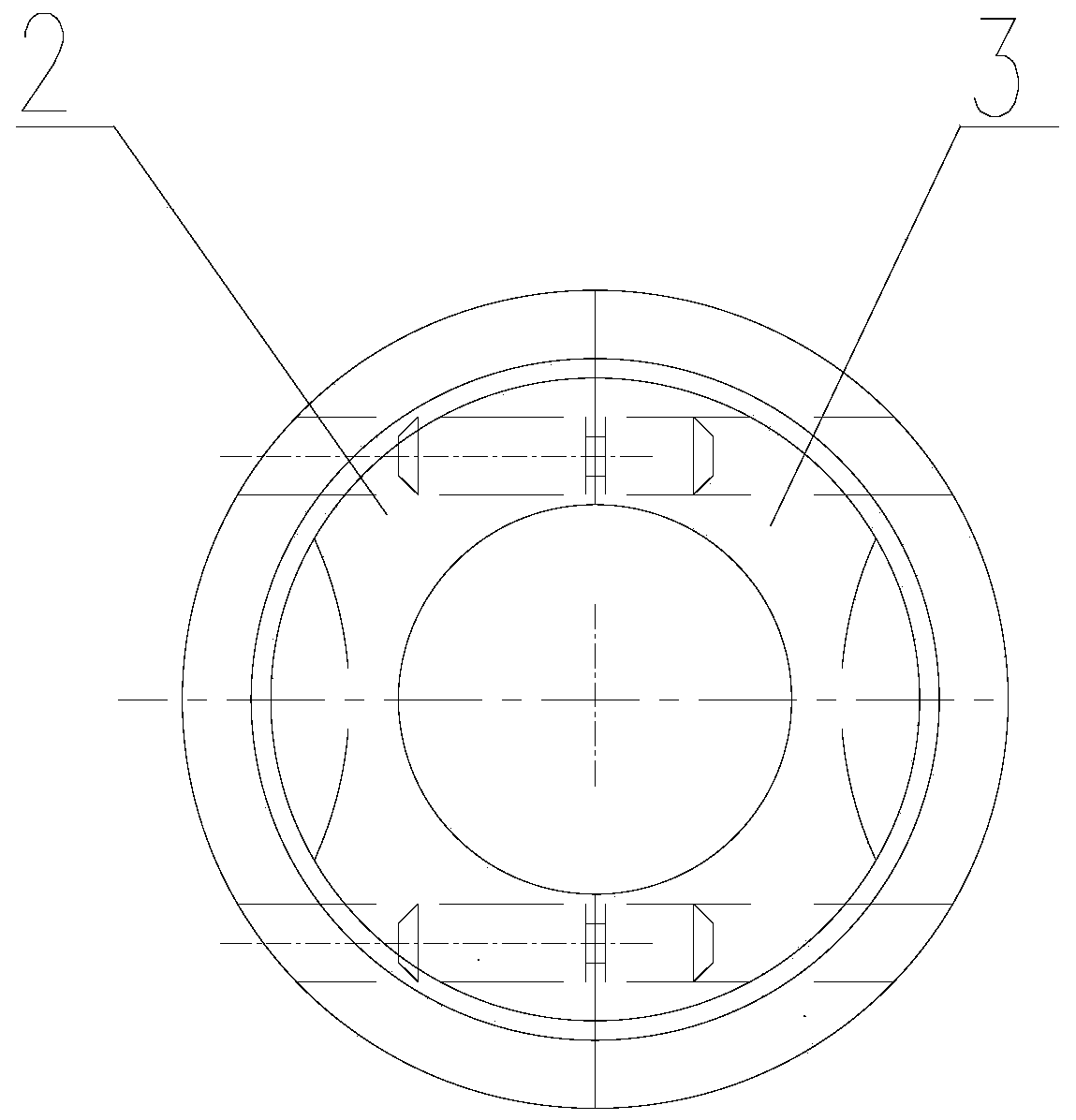

[0024] see figure 1 , figure 2 , is the structure diagram of the plunger assembly for closing processing, including sliding pin 1, left split sleeve 2, and right split sleeve 3;

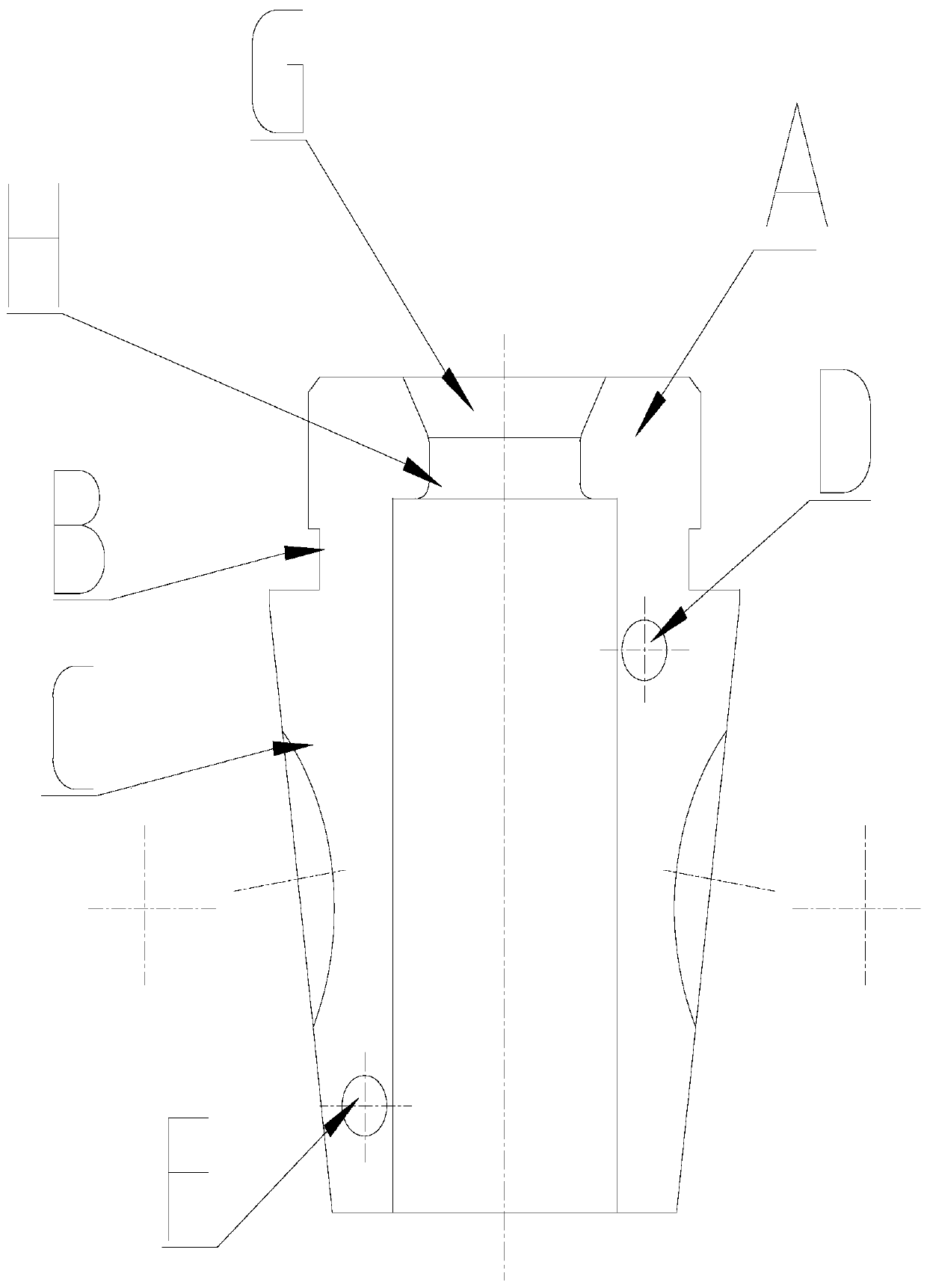

[0025] Such as image 3 Shown is the structure of left split sleeve 2, right split sleeve 3. The left open sleeve 2 and the right open sleeve 3 are both semi-revolving structures, which are combined into a revolving structure. The revolving structure is divided into two parts, which are cylinder A, semi-conical frustum C, and the diameter of cylinder A Smaller than the diameter of the connecting surface between the semi-conical frustum C and the cylinder A, the cylinder A is provided with a cylindrical hole H and a cylindrical hole J in turn, and the semi-conical frustum C of the rotary structure is provided with an asymmetric through cylindrical hole D an

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap