Machining center electric spindle and machining center

A machining center and electric spindle technology, applied in metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problems of long overhang of the front bearing and weak rigidity of the spindle, and achieve wide application range, prolong service life, The effect of increasing hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

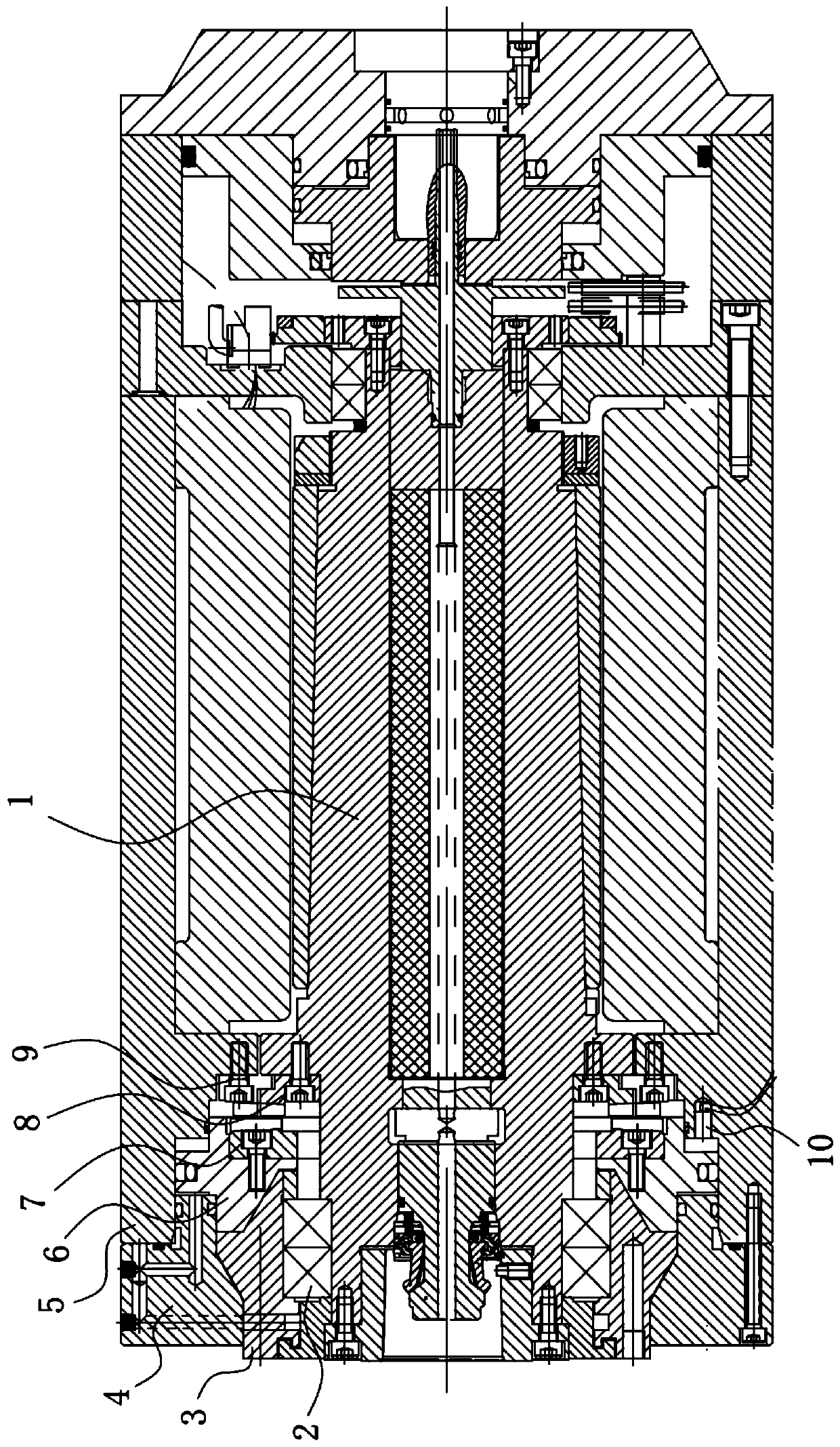

[0024] The embodiment discloses an electric spindle of a machining center and a machining center including the electric spindle, so that the machining center has turning and milling conversion functions. Such as figure 1 As shown, the electric spindle of the machining center includes a shaft core 1, and a front bearing group 2 is sleeved on the outside of the shaft core 1, and a turning and milling conversion mechanism is arranged on the outside of the shaft core 1 and at the rear end of the front bearing group 2. The milling conversion mechanism is configured such that the shaft core 1 can rotate in the front bearing group 2 when the milling process or the drilling process needs to be performed, and the shaft core 1 is fixed relative to the front bearing group 2 when the turning process needs to be pe

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap