Laser welding clamp for grillwork

A laser welding fixture and grid technology, applied in laser welding equipment, welding equipment, welding equipment and other directions, can solve problems such as difficulties in automatic welding, and achieve the advantages of convenient automatic welding processing, convenient and fast fixing, and improvement of welding efficiency and welding accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

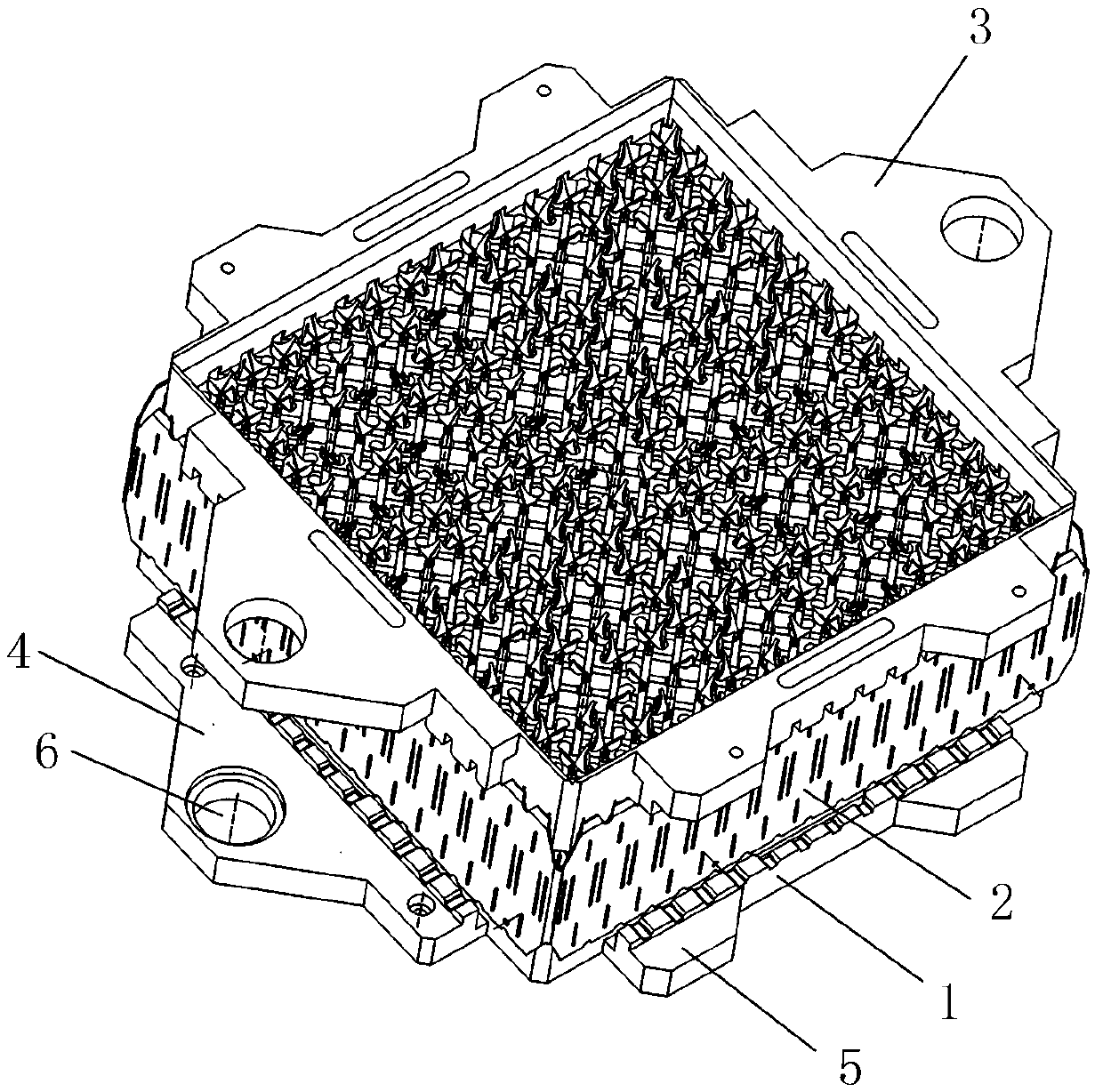

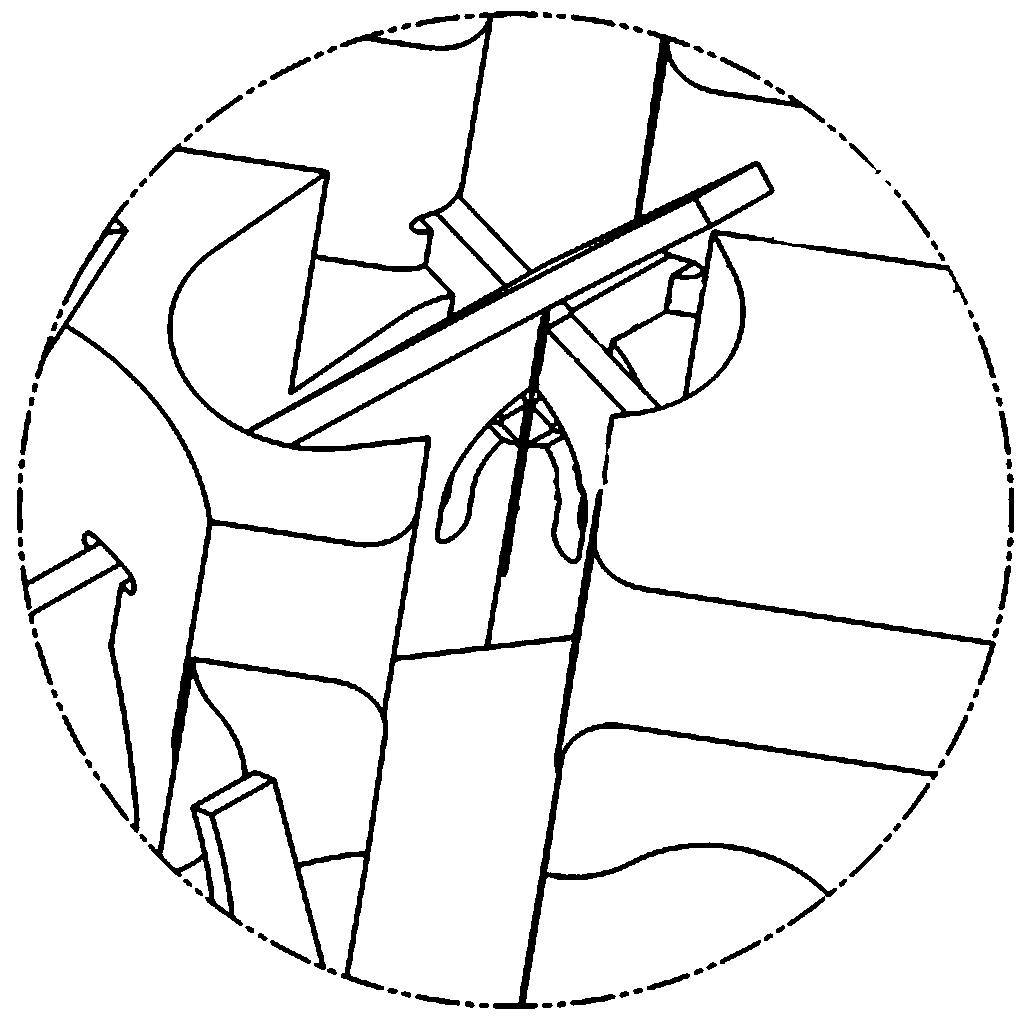

[0018] Such as figure 1 As shown, a grid laser welding jig includes a bottom plate 1 , a cover plate 3 and a side panel 2 . The side panel 2 is arranged between the bottom panel 1 and the cover panel 3, and both the bottom panel 1 and the cover panel 3 are provided with a slot, and the side panel 2 is clamped between the bottom panel 1 and the cover panel 3 through the slot. After the base plate 1, the cover plate 3 and the side wall plate 2 are fixed, a cuboid space is formed in the middle thereof, and the grid to be welded is placed in the cuboid space. The bottom plate 1 is provided with positioning pins, and the cover plate 3 is provided with corresponding pin holes for positioning, and the positioning pins pass through gaps in the grid that do not need to be welded to avoi

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap