Anti-skid and anti-fouling tableware paint and preparation method thereof

A technology for tableware and anti-fouling flow, applied in the direction of antifouling/underwater coatings, biocide-containing paints, coatings, etc. Suitable for tableware coatings and other issues, to achieve the effect of improving ornamental value, facilitating mass production, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with specific examples, but it is by no means a limitation of the present invention.

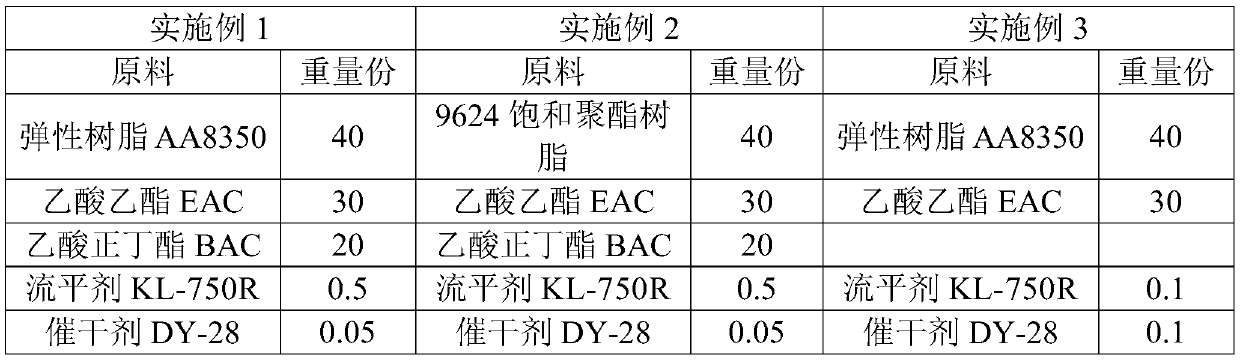

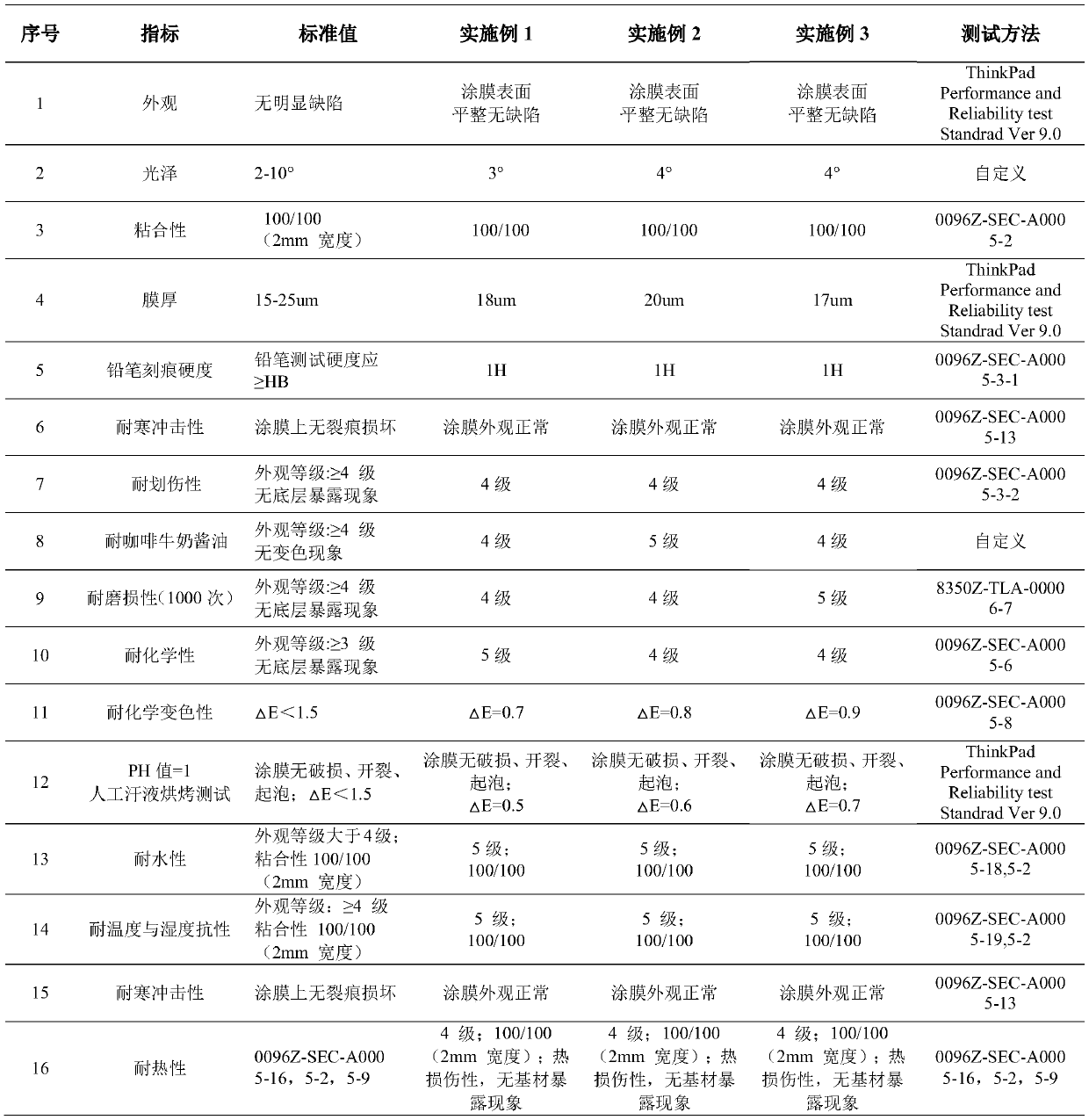

[0023] A preparation of an anti-skid and stain-resistant tableware paint, comprising the following components and contents in parts by weight: 40-60 parts of polyester resin, 30-50 parts of solvent, 0.1-5 parts of anti-stain and leveling agent, and 0.01-0.1 part of drier. Wherein, the polyester resin is a high-solid hydroxyl saturated polyester resin, and the polyester resin is selected from commercially available models as one or two mixed in AA8350 resin or 9624 saturated polyester resin;

[0024] The solvent is selected from one or a mixture of ethyl acetate (EAC) or n-butyl acetate (BAC); KL-750R anti-fouling and leveling agent; drier is DY-28. Concrete preparation steps:

[0025] (1) Prepare materials according to the formula, mix polyester resin and solvent, 1200 rpm, stir and disperse for 5-10 minutes, (2) add

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap