Purification device and process suitable for high-boiling-point chemical raw materials

A chemical raw material, high boiling point technology, applied in the direction of chemical instruments and methods, air heaters, fixed tubular conduit components, etc., can solve the problems of energy waste, low production efficiency, carbon deposition, etc., to improve cooling efficiency and thermal efficiency , the effect of reducing the height of the tower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

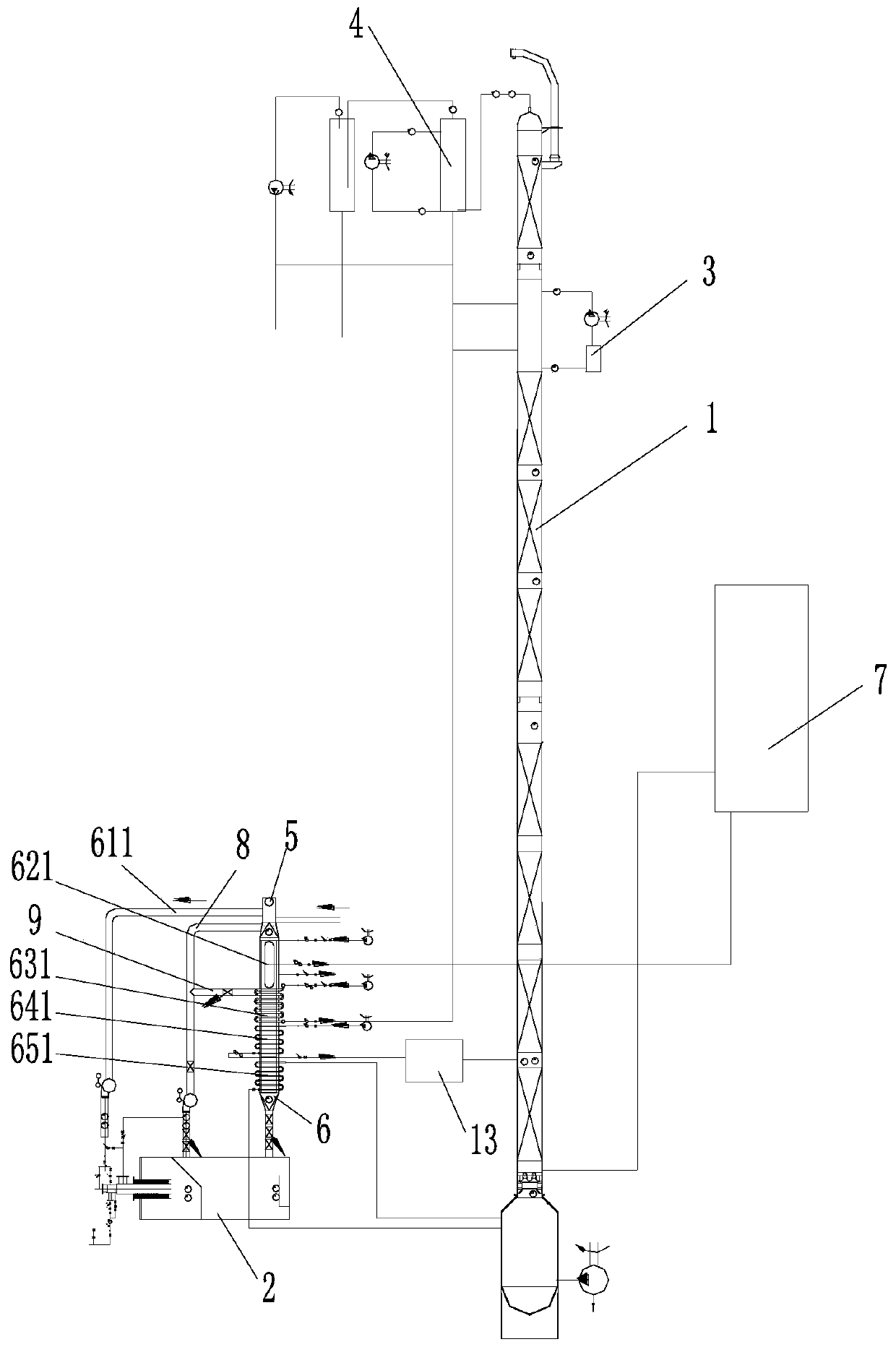

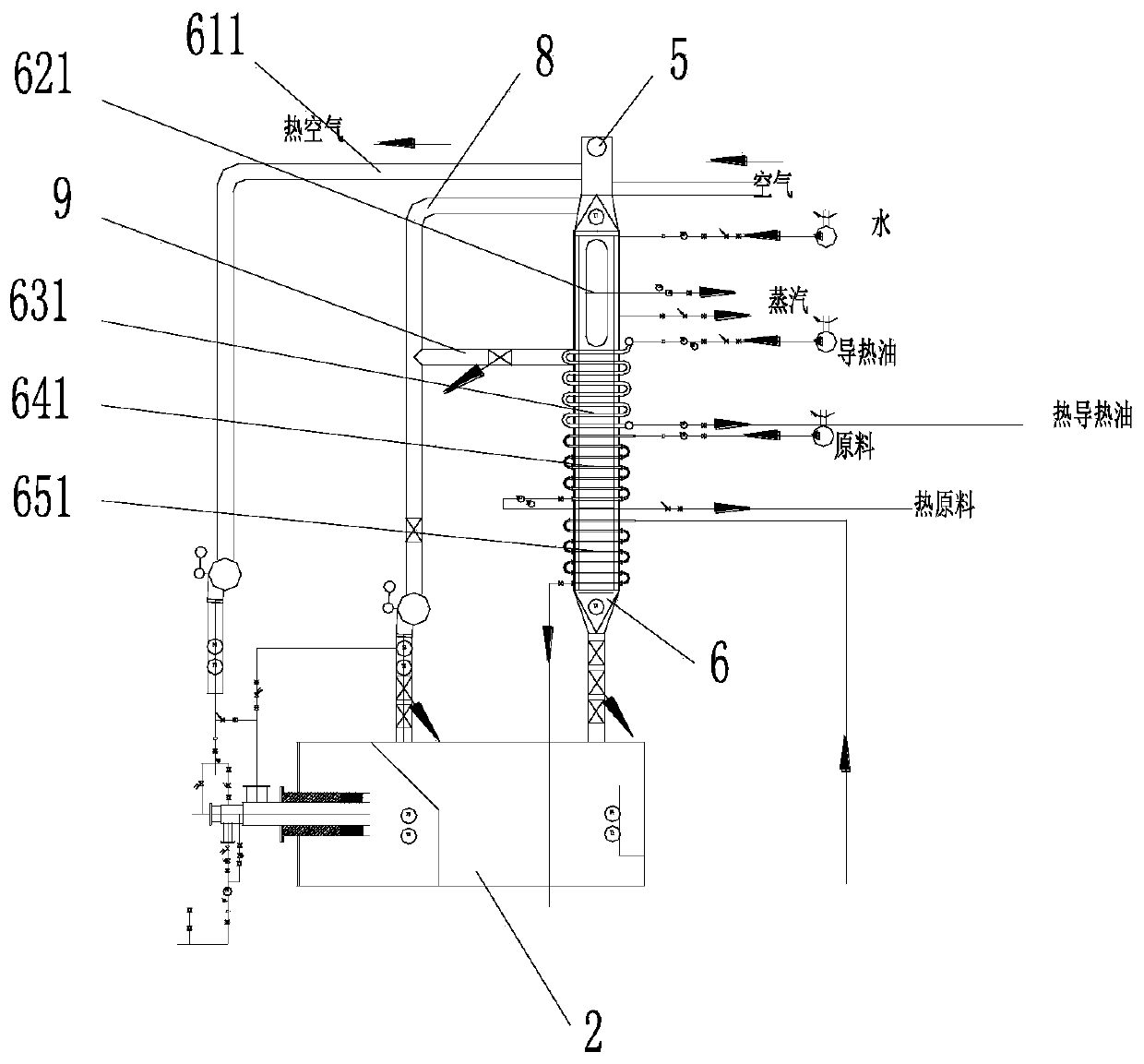

[0021] Such as Figure 1-Figure 2 , a purification device suitable for high-boiling point chemical raw materials, including a purification tower 1, a hot blast stove 2, a first condenser 3 is arranged on the upper part of the purification tower 1, a second condenser 4 is connected to the top of the purification tower 1, and the hot blast stove 2 utilizes waste heat The device is connected to the chimney 5, and the waste heat utilization device includes a flue 6, and the flue 6 is provided with an air heating section 610, a steam heating section 620, a heat transfer oil heating section 630, a raw material preheating heating section 640, Residual material reboiling heating section 650, air heating section 610 is provided with preheating air pipeline 611, the inlet of preheating air pipeline 611 leads into air, the outlet of preheating air pipeline 611 connects the burner of hot blast stove 2, steam A steam pipe 621 is arranged on the heating section 620, the inlet of the steam pipe

Embodiment 2

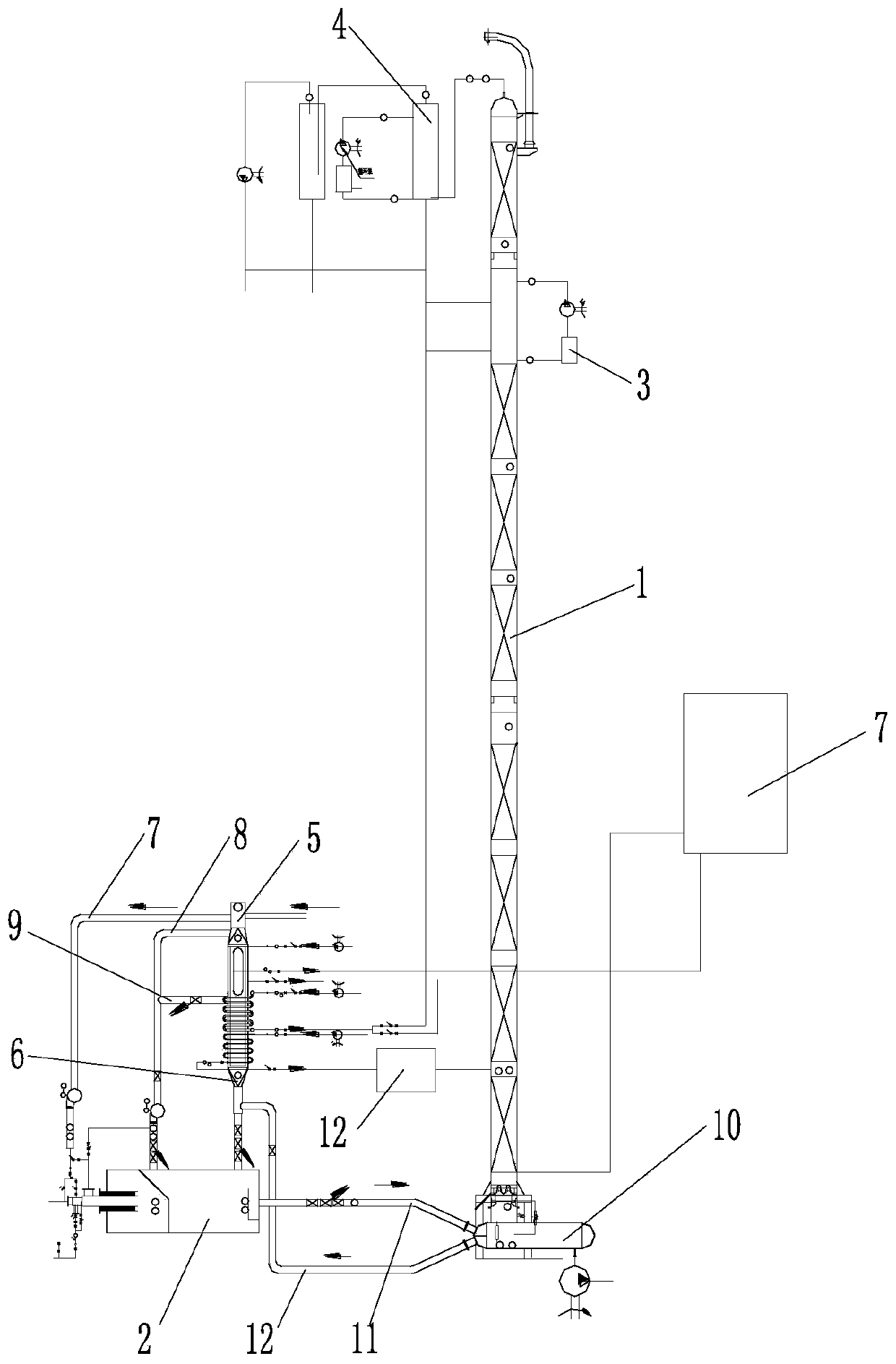

[0026] Such as Figure 3-Figure 4 , a purification device suitable for high-boiling point chemical raw materials, including a purification tower 1, a hot blast stove 2, a first condenser 3 is arranged on the upper part of the purification tower 1, a second condenser 4 is connected to the top of the purification tower 1, and the hot blast stove 2 utilizes waste heat The device is connected to the chimney 5, and the waste heat utilization device includes a flue 6. The air heating section 610, the steam heating section 620, the heat transfer oil heating section 630, and the raw material preheating heating section 640 are arranged on the flue 6 from top to bottom. The air heating section 610 is provided with a preheating air pipeline 611, the inlet of the preheating air pipeline 611 is fed with air, the outlet of the preheating air pipeline 611 is connected to the burner of the hot blast stove 2, and the steam heating section 620 is arranged with a steam pipeline 621 , the inlet of t

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap