Feed hopper on mining iron removal equipment

A technology for feeding hoppers and equipment, applied in the field of mining machinery, can solve the problems affecting the adsorption of the magnet mechanism and the detachment of ferromagnetic impurities, and achieve the effect of preventing clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

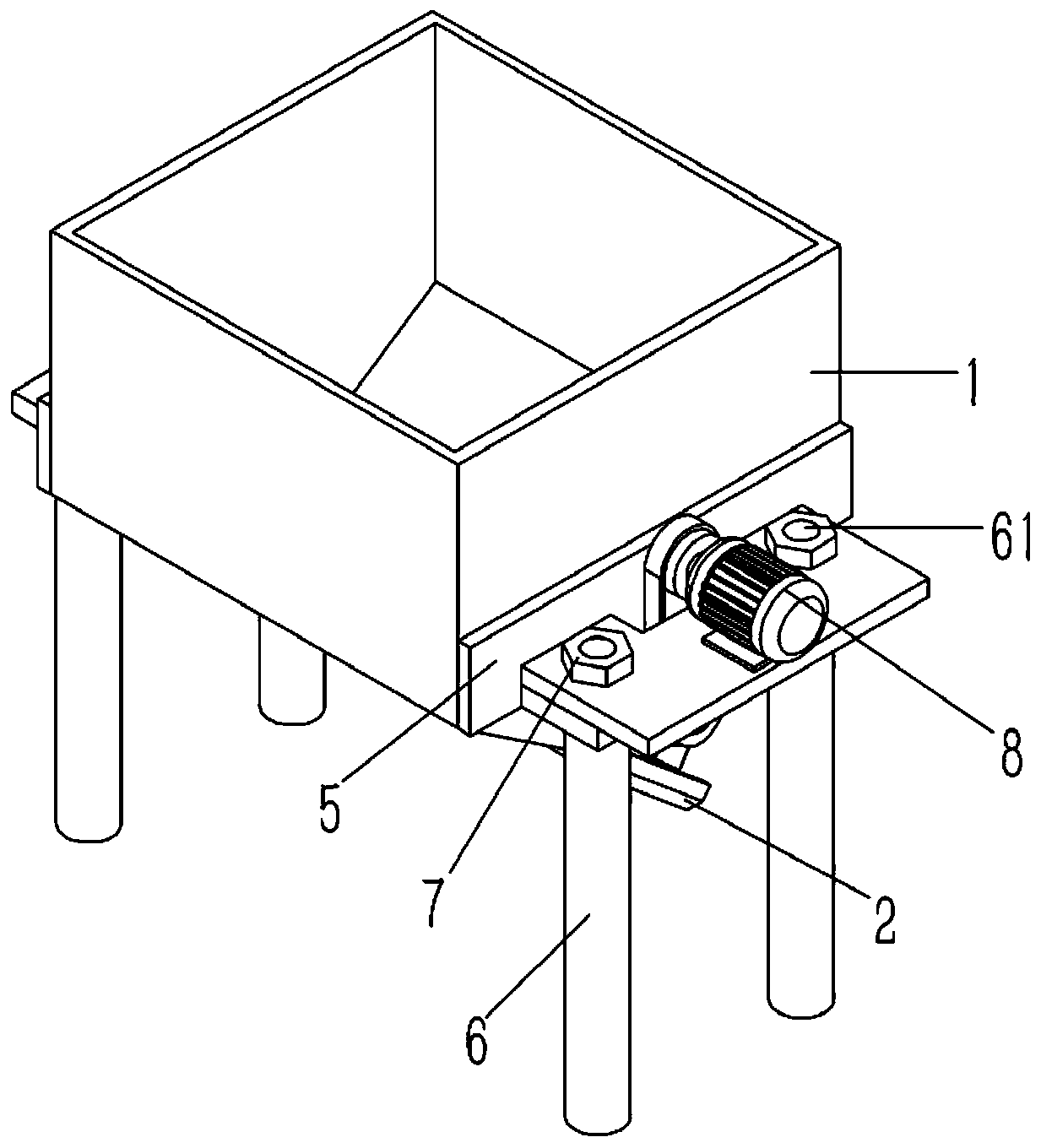

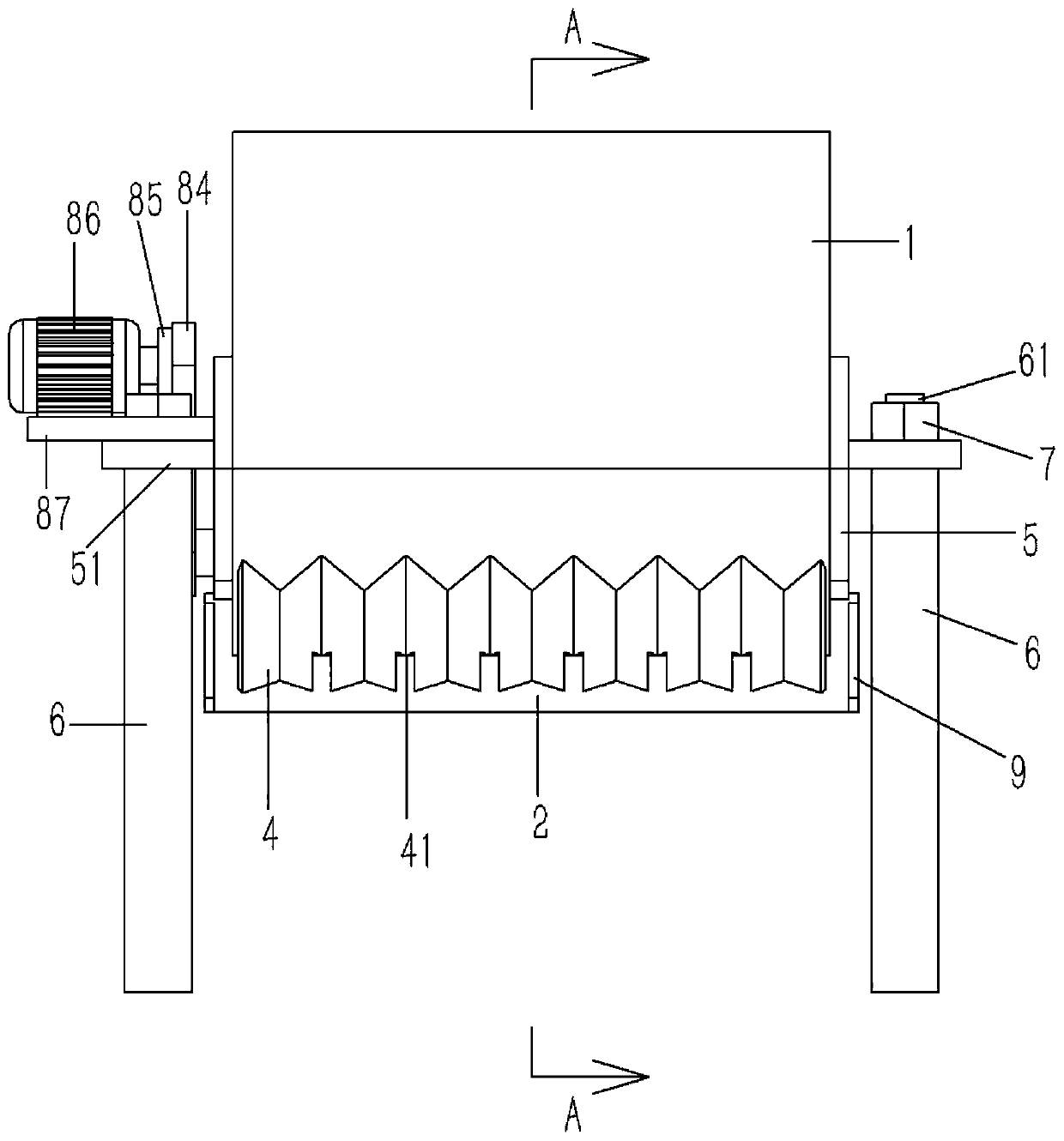

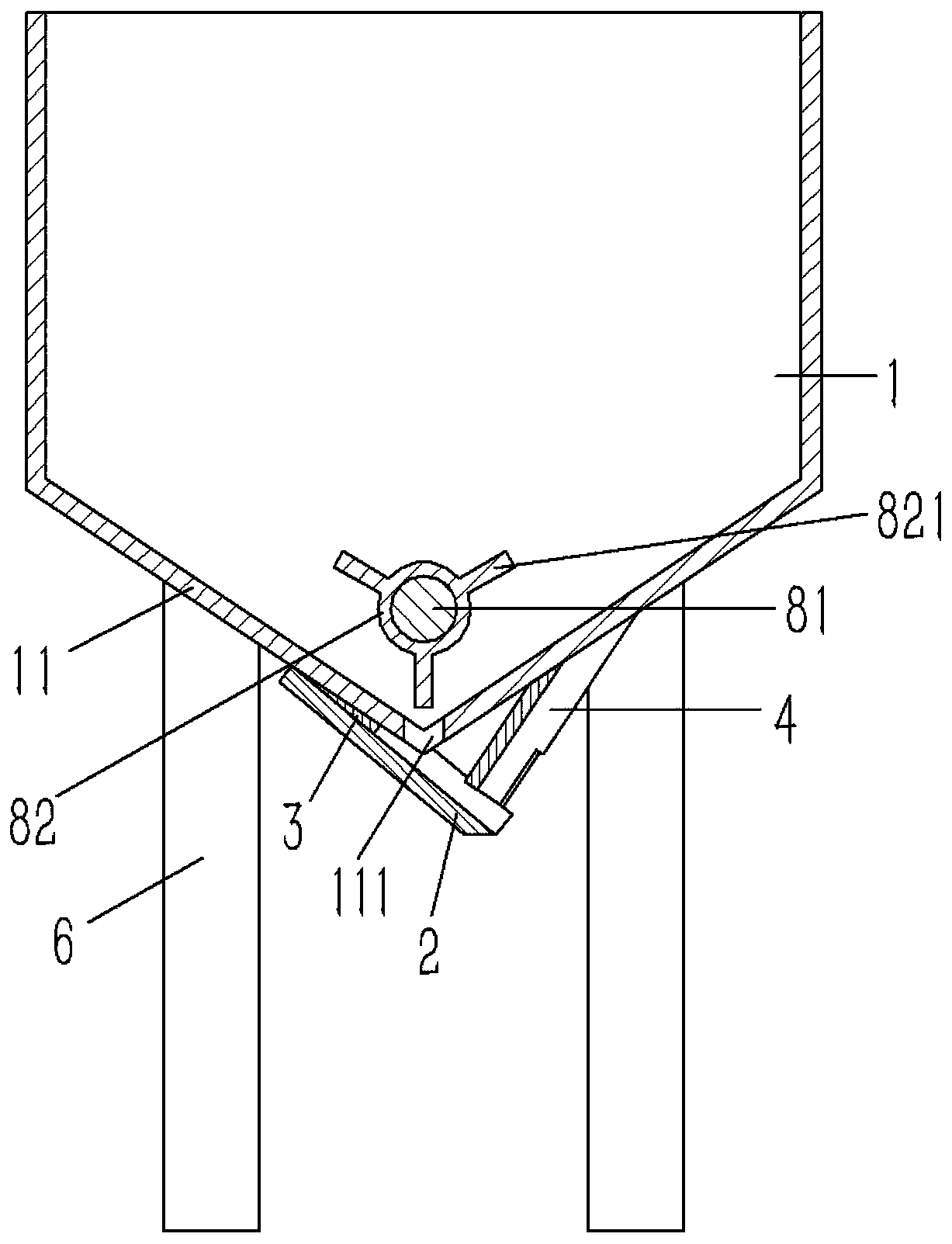

[0020] Example: see Figures 1 to 5 As shown, a feed hopper on a mining iron removal equipment includes a hopper 1, the lower end of the hopper 1 is formed with a tapered bucket body 11, and the lower end of the bucket body 11 is formed with several discharge ports 111; The rear end face of the deflector 2 is fixed with an inclined deflector 2, the front end of the deflector 2 is located directly below the front end of the bucket body 11, and a corrugated material retaining plate 4 is provided above the front of the deflector 2. There is a gap between the plate 4 and the deflector 2; the crest of the baffle plate 4 is facing the discharge port 111 on the bucket body 11, and the trough of the baffle plate 4 is distributed in the adjacent discharge port 111 Between, the upper end of the baffle plate 4 is fixed on the front end surface of the bucket body 11; the two side walls of the hopper 1 are fixed with a T-shaped support plate 5, and a number of horizontal support plates 51 are

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap