Prestressed concrete hollow floor slab and construction method thereof

A technology of hollow floor slab and construction method, which is applied in the direction of floor slabs, buildings, and building components, etc., which can solve the problems of ineffective control of production costs, high breakage rate of protruding blocks at corners, and easy leakage at joints, etc., to achieve hollow The effect of high efficiency, increased crack resistance and tensile strength between plates, and fast production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0035] The embodiments of the present invention will be described in further detail below with reference to the accompanying drawings.

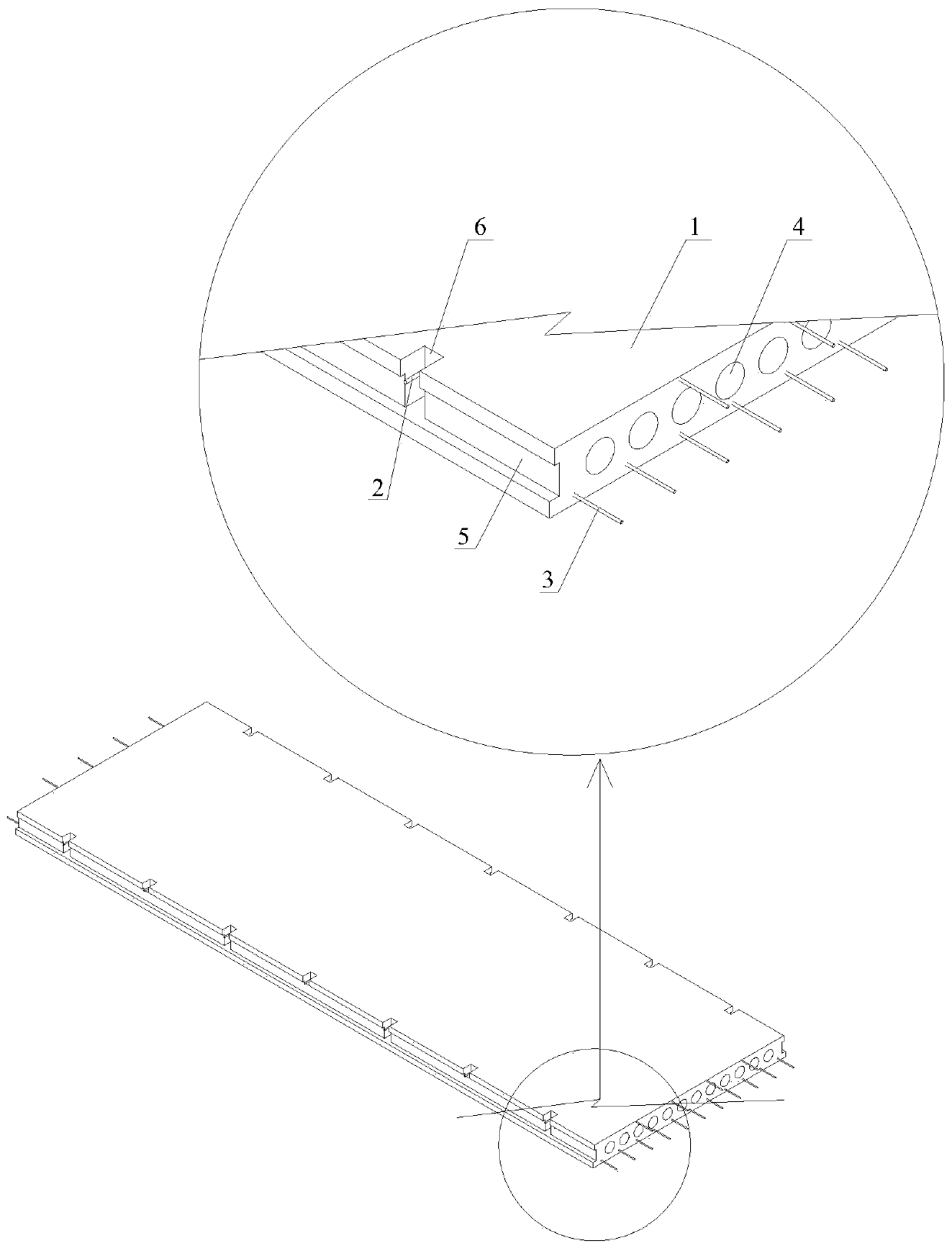

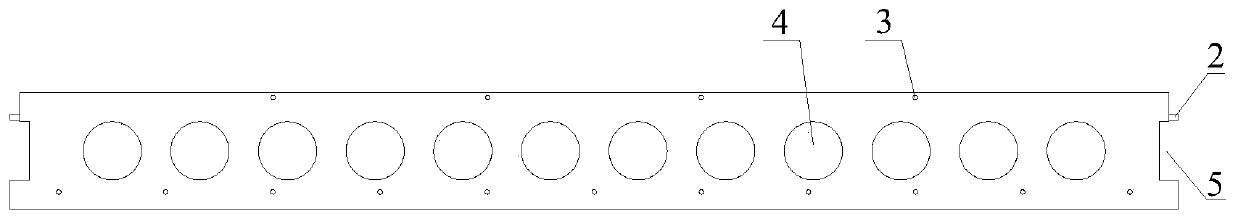

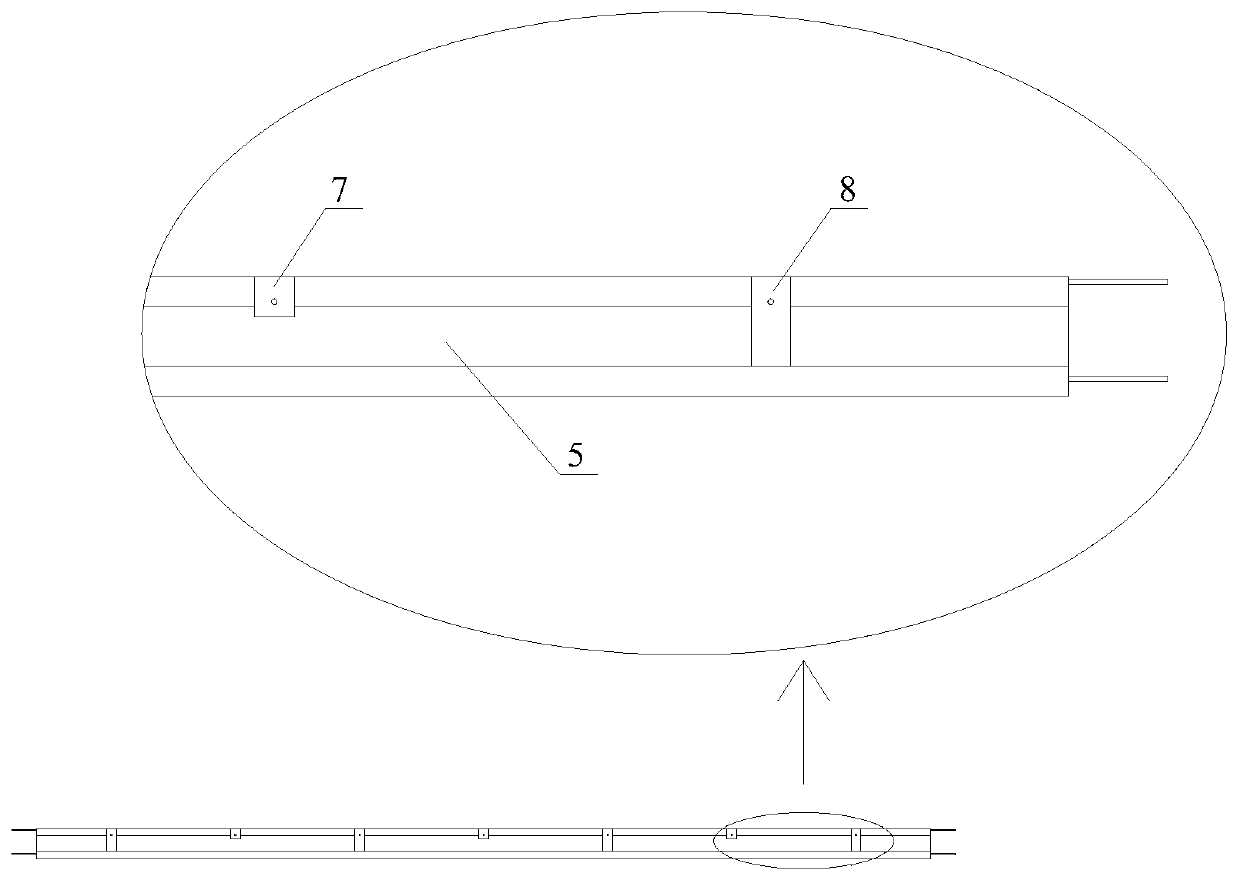

[0036] See figure 1 The structure diagram of a pre-stressed concrete hollow floor in the embodiment of the present invention is shown, which includes a slab body 1, a transverse reinforcement 2, and a longitudinal reinforcement 3. The plate body 1 is provided with at least one through hole 4, and double-sided ribs are used. The transverse ribs 2 and longitudinal ribs 3 are embedded in the plate body 1. The top surface of the plate body 1 is provided with staggered transverse ribs 2, longitudinal ribs 3, and plate body 1. The longitudinal ribs 3 are evenly arranged on the bottom surface. Both sides of the top surface of the board body 1 are also provided with transverse rib grooves 6, the transverse rib grooves 6 on both sides are arranged in pairs, and both ends of the transverse rib 2 extend into a pair of transverse rib grooves 6 but do not exten

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap