Detection device of chip for electronic equipment

A technology of electronic equipment and detection devices, applied in measuring devices, material analysis through optical means, instruments, etc., can solve the problems of inability to accurately photograph chips, inconvenient removal of chips, and inability to detect chips, etc., to solve the problem of inability to accurately photograph integrated chips , improve the versatility, and solve the effect of inconvenient removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

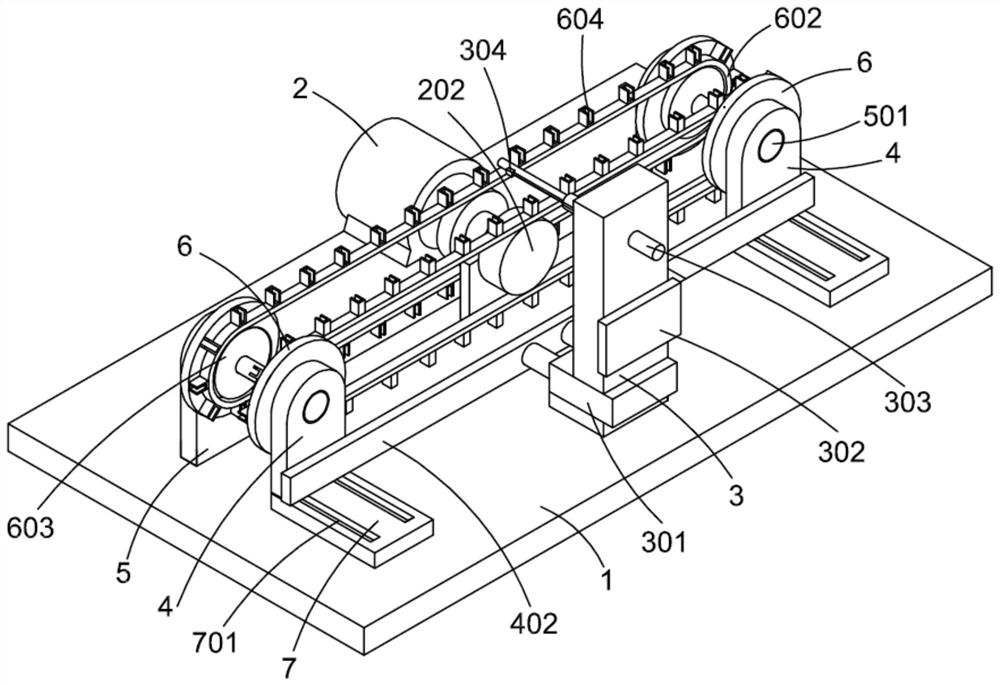

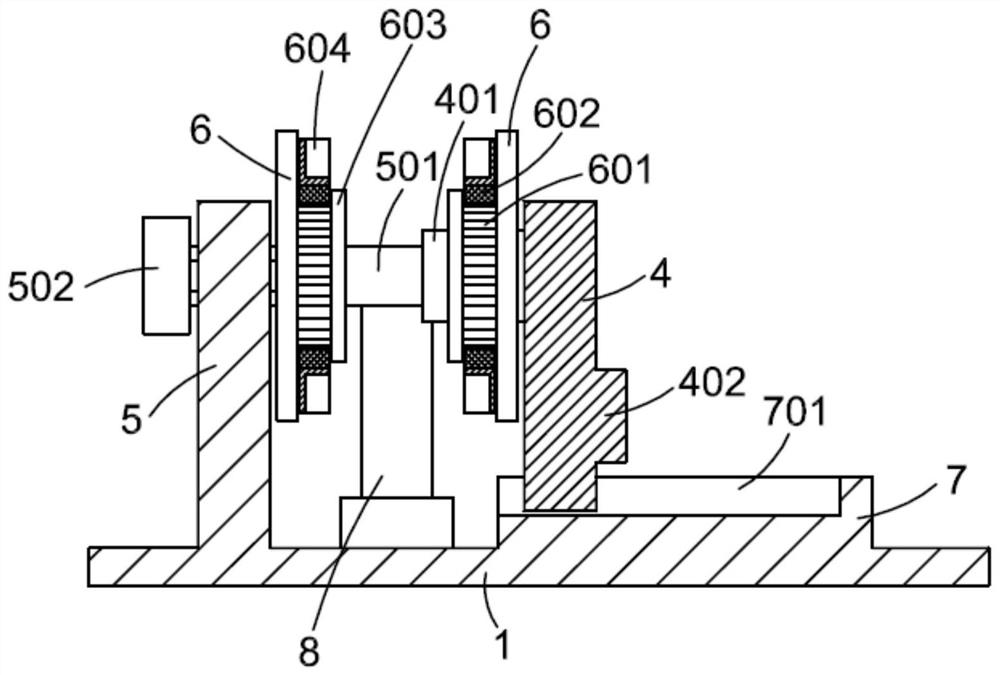

[0027] Embodiment 1: A detection device for chips used in electronic equipment, including a base plate 1, a motor 2 installed on the upper surface of the base plate 1, several fixed plates 5 arranged at intervals on the upper surface of the base plate 1, and several fixed plates 5 facing each other. The movable plate 4 provided, the motor 2 is installed on the outside of the fixed plate 5 or the movable plate 4, a slide plate 7 is arranged between the base plate 1 and the movable plate 4, and the lower surface of the movable plate 4 is movably installed on the on the slide plate 7, so that the movable plate 4 can move towards or away from the fixed plate 5;

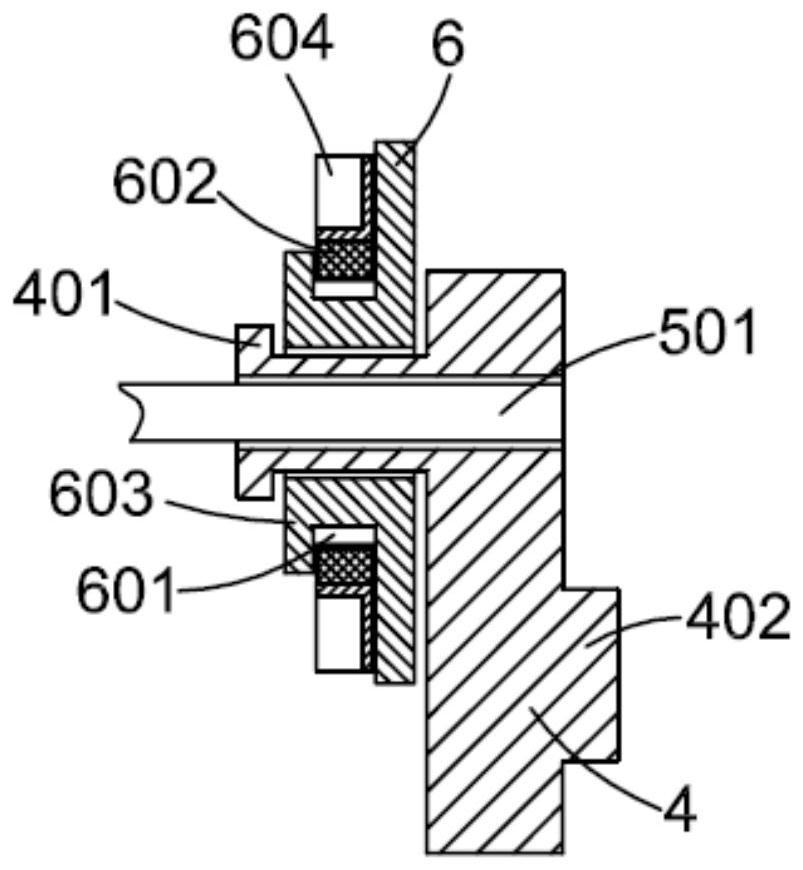

[0028] A limit shaft 501 is connected between the fixed plate 5 and the movable plate 4 which are arranged oppositely. On the side surface of the movable plate 4 close to the fixed plate 5, there is a convex tube 401 facing the fixed plate 5. The central opening of the convex tube 401 is There is a through hole for the limit

Embodiment 2

[0032] Embodiment 2: A detection device for chips used in electronic equipment, including a base plate 1, a motor 2 installed on the upper surface of the base plate 1, several fixed plates 5 arranged at intervals on the upper surface of the base plate 1, and several fixed plates 5 facing each other. The movable plate 4 provided, the motor 2 is installed on the outside of the fixed plate 5 or the movable plate 4, a slide plate 7 is arranged between the base plate 1 and the movable plate 4, and the lower surface of the movable plate 4 is movably installed on the on the slide plate 7, so that the movable plate 4 can move towards or away from the fixed plate 5;

[0033] A limit shaft 501 is connected between the fixed plate 5 and the movable plate 4 which are arranged oppositely. On the side surface of the movable plate 4 close to the fixed plate 5, there is a convex tube 401 facing the fixed plate 5. The central opening of the convex tube 401 is There is a through hole for the limit

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap