Refitting process of ship lashing bridge of large containers

A technology of container ships and lashing bridges, which is applied to ships and other directions, can solve problems such as large trim and difficulty in positioning and installing new lashing bridges, and achieve the effects of reducing construction difficulty, simple structure, and exquisite design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0058] In order to solve the deficiencies and defects of the existing technology, the present invention provides a large-scale container ship lashing bridge modification process, which reduces the difficulty of construction, shortens the overall installation time, not only ensures the accuracy of installation, but also reduces the cost of repair and modification. the cost of.

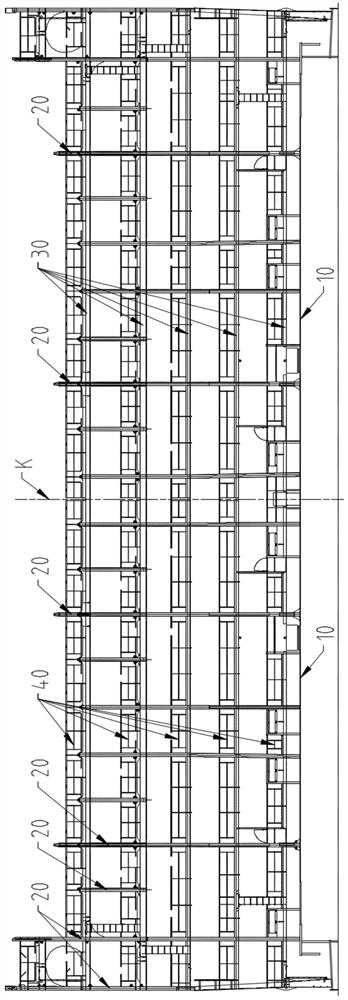

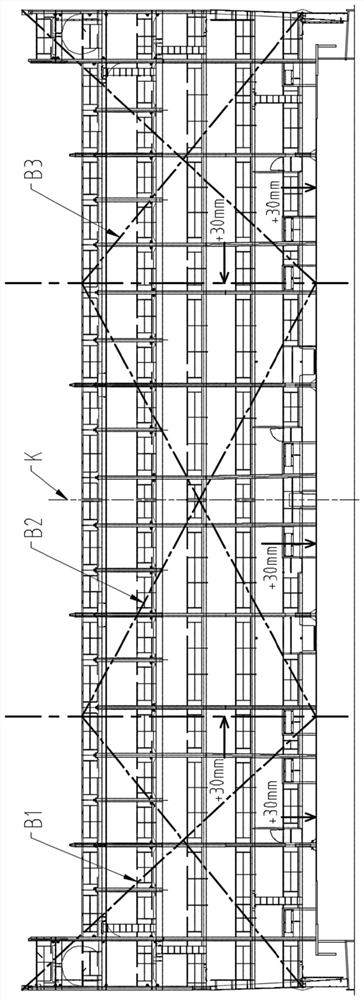

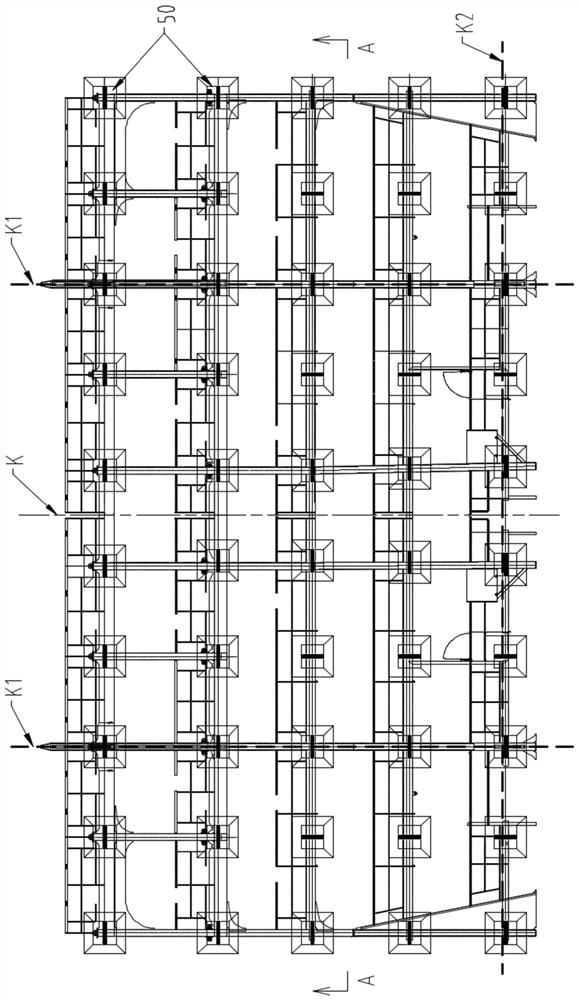

[0059]In the description of the embodiment of the present invention, the present invention will be specifically described by taking the modification project of the lashing bridge of the "MSC-16K" series large container ship as an example. The main modification contents of this series of large container ships include: cabin No.3 to cabin No.10, demolition of the old lashing bridge on the third floor above the hatch circumference 10, and a new lashing bridge on the fifth floor. like figure 1 , which is a transverse schematic view of the new lashing bridge in the present invention, among the figures, K is th

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap