High-precision auxiliary type angle grinder based on lithium battery power supply

A technology of angle grinder and lithium battery, which is applied to portable grinding machines, grinding machines, grinding drive devices, etc., and can solve the problems of large volume, inconvenient use, and laborious lifting of lithium batteries, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with various embodiments shown in the drawings. However, these embodiments do not limit the present invention, and structural, method, or functional changes made by those skilled in the art according to these embodiments are included in the protection scope of the present invention.

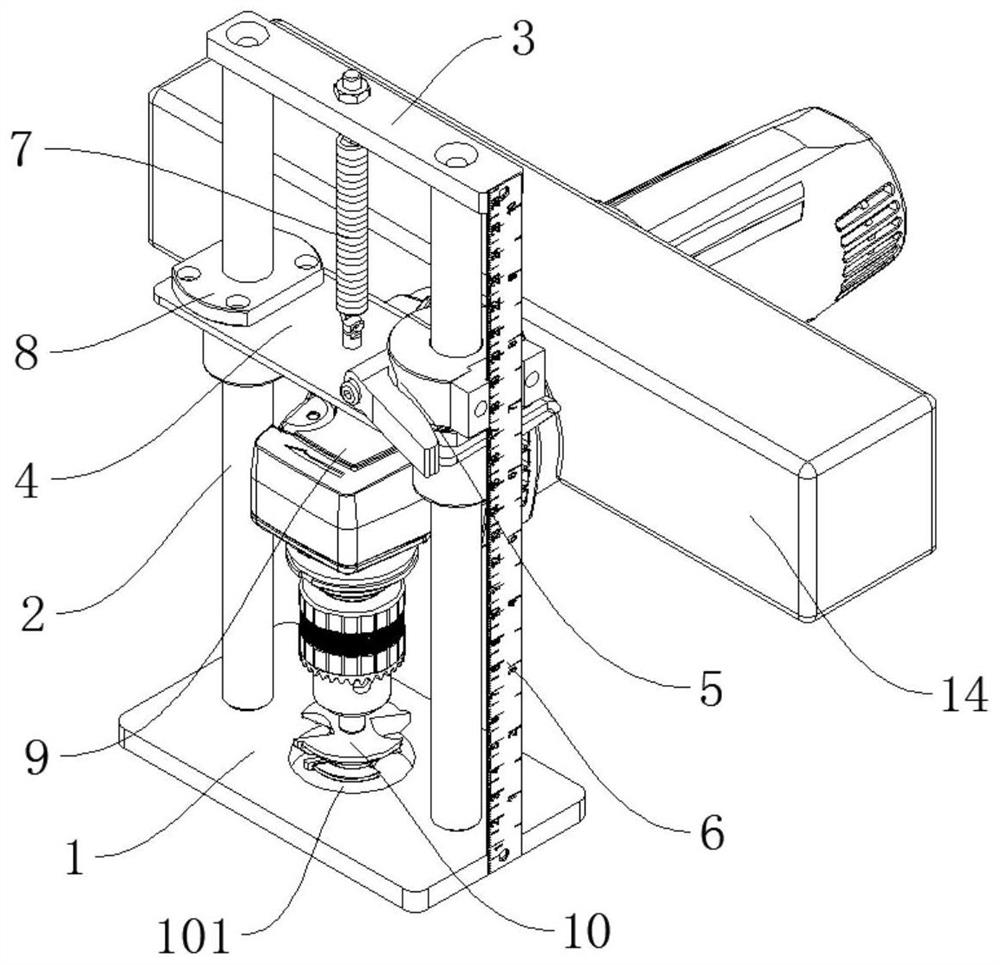

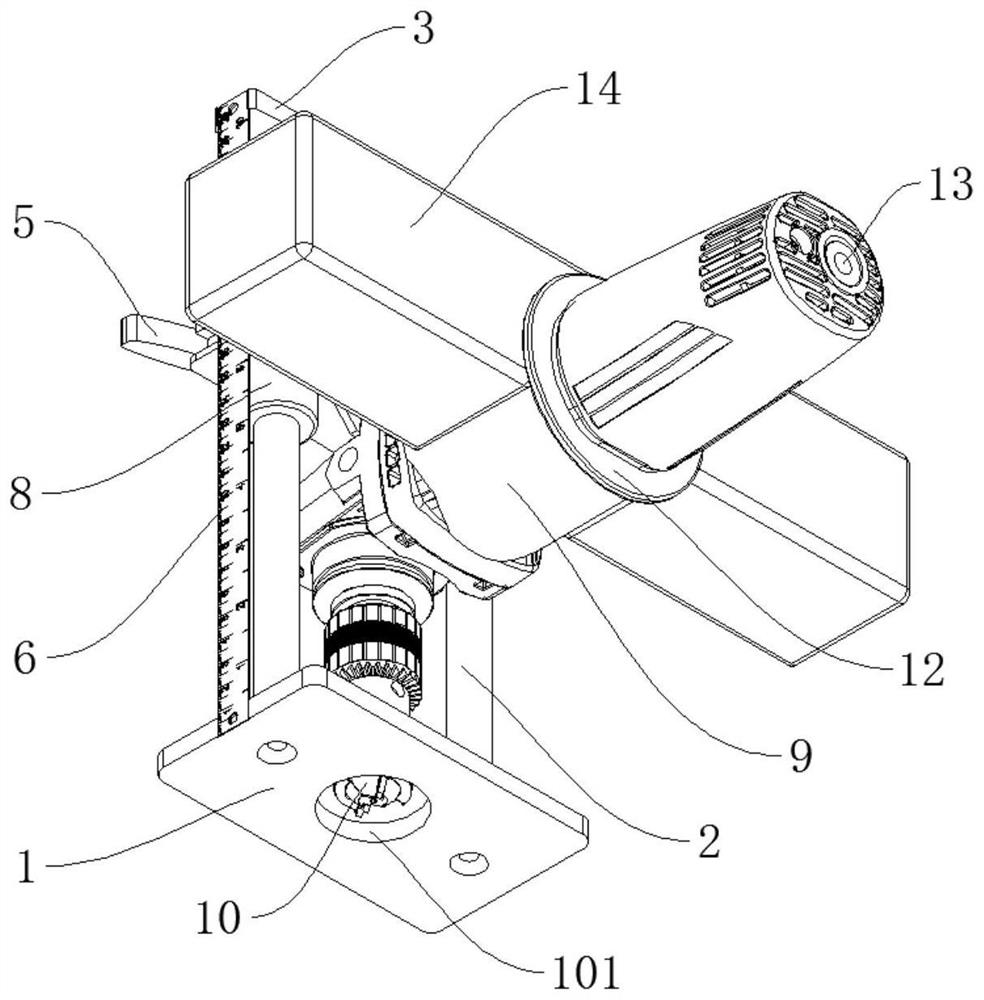

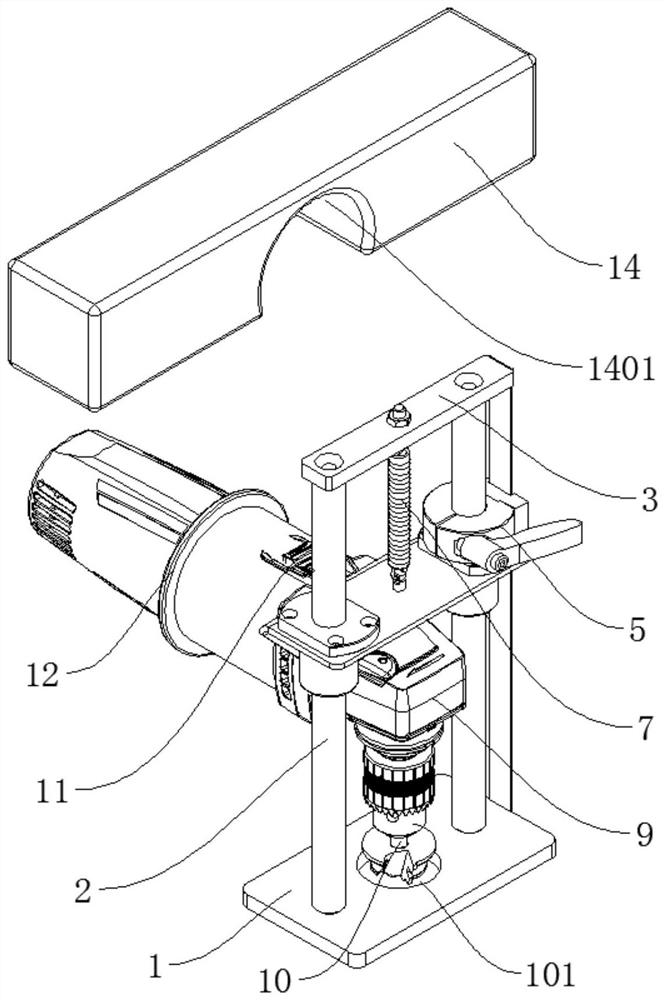

[0028] An embodiment of the present invention discloses a high-precision auxiliary angle grinder powered by a lithium battery, which includes an angle grinder body 9 and a high-precision auxiliary device. A grinding disc 10 is installed at one end of the angle grinder body 9, and the angle grinder The body 9 is provided with a lithium battery clamping part 11, and the angle grinder body 9 is equipped with a lithium battery assembly 14, and the lithium battery assembly 14 is provided with a discharge connection part 1401 matching the lithium battery clamping part 11, which is connected through discharge. The contacts on the

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap