Preparation method of nanocrystalline neodymium-iron-boron permanent magnet block

A technology of NdFeB and nanocrystals, which is applied in the direction of magnetic objects, inductor/transformer/magnet manufacturing, magnetic materials, etc., can solve the problems of less optimistic preparation efficiency, poor uniformity, and high cost, and achieve high efficiency uniformity and improved Consistency, anti-oxidation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

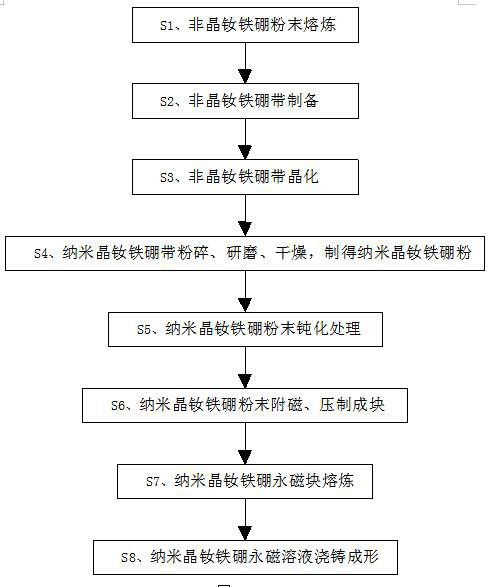

Image

Examples

Embodiment 1

[0025] A method for preparing a nanocrystalline NdFeB permanent magnet block, comprising amorphous NdFeB powder, the preparation method of the nanocrystalline NdFeB permanent magnet block includes the following steps:

[0026] S1. Put the amorphous NdFeB powder in a melting furnace for smelting. The melting temperature is 1270°C. After smelting, pour the amorphous NdFeB solution in the melting furnace into the holding furnace. The temperature in the holding furnace is Control at 1200°C, holding time is 25min;

[0027] S2. Inject the amorphous NdFeB solution in the holding furnace into the quartz tube by bottom injection, and then spray it onto the surface of the high-speed rotating copper roller through the nozzle at the bottom of the quartz tube. The copper roller rotates at a speed of 15m / s. Among them, the flow rate of the amorphous NdFeB solution can be adjusted by using argon to control the pressure, so as to obtain the amorphous NdFeB ribbon;

[0028] S3. Put the amorpho

Embodiment 2

[0035] A method for preparing a nanocrystalline NdFeB permanent magnet block, comprising amorphous NdFeB powder, the preparation method of the nanocrystalline NdFeB permanent magnet block includes the following steps:

[0036] S1. Put the amorphous NdFeB powder in a melting furnace for melting, the melting temperature is 1570°C; after melting, pour the amorphous NdFeB solution in the melting furnace into the holding furnace, the temperature in the holding furnace Control at 1400°C, holding time is 40min;

[0037] S2. Inject the amorphous NdFeB solution in the holding furnace into the quartz tube by bottom injection, and then spray it onto the surface of the high-speed rotating copper roller through the nozzle at the bottom of the quartz tube. The copper roller rotates at a speed of 25m / s. Among them, the flow rate of the amorphous NdFeB solution can be adjusted by using argon to control the pressure, so as to obtain the amorphous NdFeB ribbon;

[0038] S3. Put the amorphous Nd

Embodiment 3

[0045] A method for preparing a nanocrystalline NdFeB permanent magnet block, comprising amorphous NdFeB powder, the preparation method of the nanocrystalline NdFeB permanent magnet block includes the following steps:

[0046] S1. Put the amorphous NdFeB powder in a melting furnace for melting, the melting temperature is 1570°C; after melting, pour the amorphous NdFeB solution in the melting furnace into the holding furnace, the temperature in the holding furnace Control at 1500°C, holding time is 55min;

[0047] S2. Inject the amorphous NdFeB solution in the holding furnace into the quartz tube by bottom injection, and then spray it onto the surface of the high-speed rotating copper roller through the nozzle at the bottom of the quartz tube. The copper roller rotates at a speed of 30m / s. Among them, the flow rate of the amorphous NdFeB solution can be adjusted by using argon to control the pressure, so as to obtain the amorphous NdFeB ribbon;

[0048] S3. Put the amorphous Nd

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap