Test device and method for simulating stratum displacement caused by double-circle shield tunnel construction

A technology of tunnel construction and double-circle shield

Active Publication Date: 2020-12-11

CHONGQING JIAOTONG UNIVERSITY +1

View PDF7 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the water bag drainage method used in this test method cannot guarantee the stability of the cross-sectional shape of the tunnel during excavation.

Moreover, in order to realize the step-by-step excavation of the

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to view more

Login to view more PUM

Login to view more

Login to view more Abstract

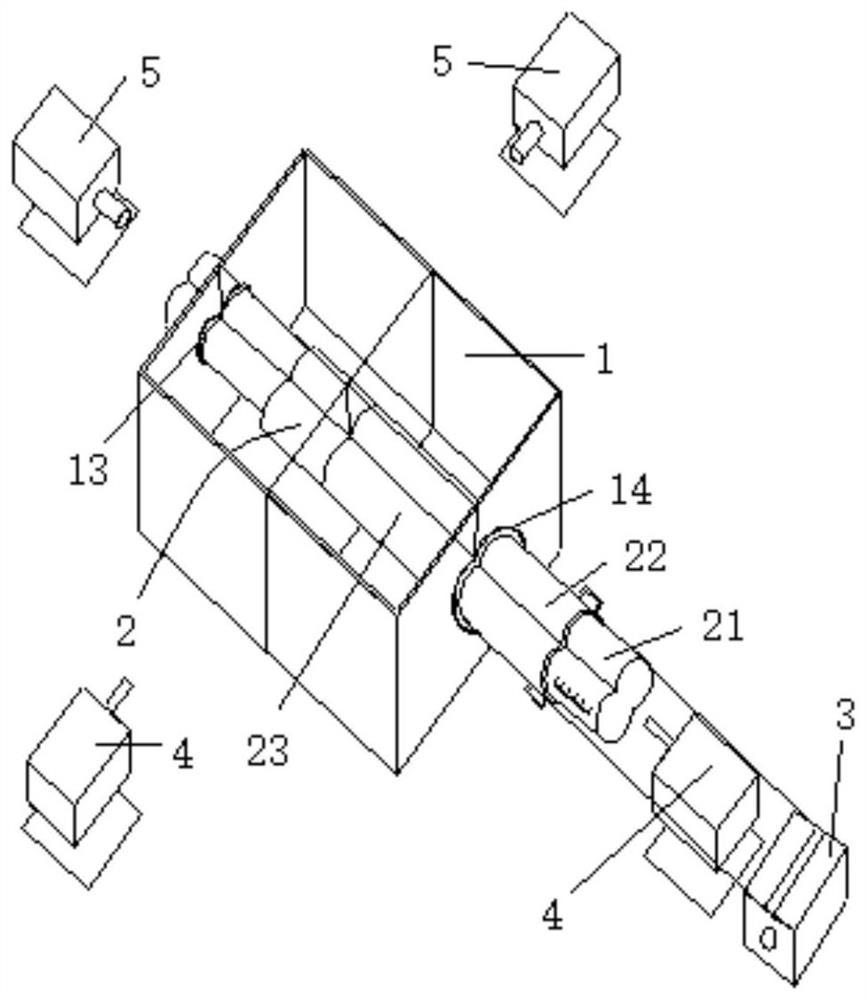

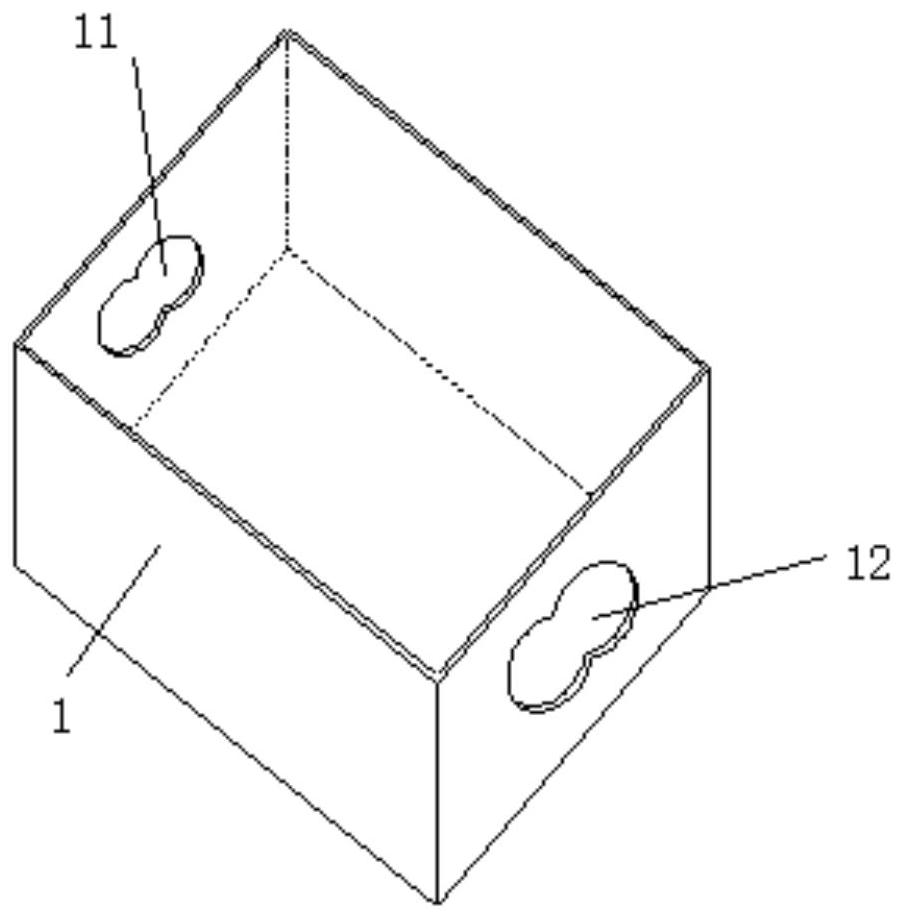

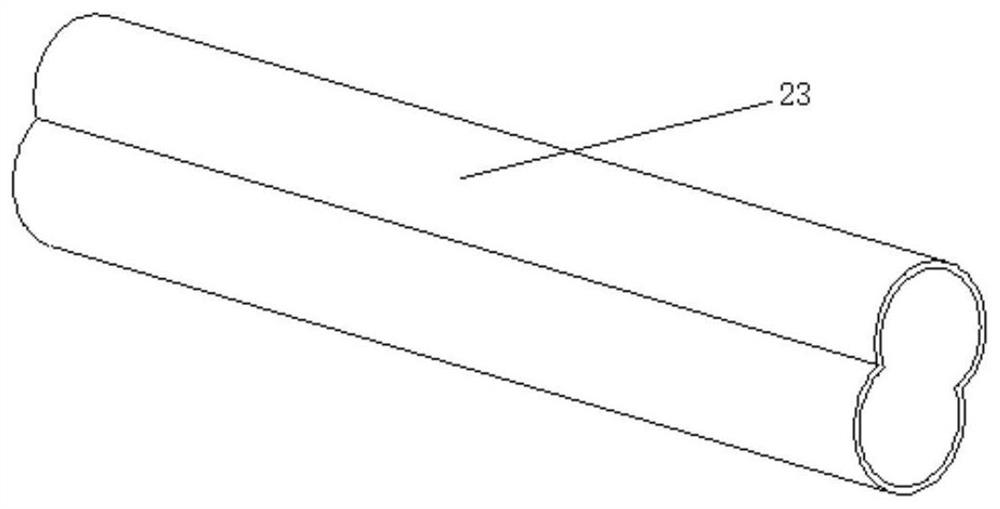

The invention relates to a test device and method for simulating stratum displacement caused by double-circle shield tunnel construction, and belongs to the field of civil engineering tests. The device comprises a transparent model box filled with transparent soil, a double-circle tunnel model, a tractor, laser emitters and cameras. The double-circle tunnel model horizontally penetrates through the transparent model box and comprises a transparent double-circle supporting column and a transparent double-circle pipe which are sleeved with each other and can slide relatively, and the transparentdouble-circle supporting column and the transparent double-circle pipe which are located in the transparent model box are embedded into transparent soil. The tractor is located outside the transparent model box and connected with the transparent double-circular pipe so as to discontinuously pull the transparent double-circular pipe to be horizontally drawn. The two laser emitters and the two cameras are arranged at the periphery of the transparent model box in a manner of corresponding to the transparent double-circular pipe, one laser emitter and one camera are arranged at the two sides of the drawing direction of the transparent double-circular pipe respectively, and the other laser emitter and the other camera are arranged at the two sides of the direction vertical to the drawing direction of the transparent double-circular pipe respectively. Operation is convenient, the structure is simple, and the simulation effect is visual and accurate.

Description

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more Application Information

Patent Timeline

Login to view more

Login to view more Owner CHONGQING JIAOTONG UNIVERSITY

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap