Intelligent carrying industrial robot with stable clamping function

An industrial robot and intelligent handling technology, applied in the industrial field, can solve the problems of limited scope of application, low practicability, and small scope of application, and achieve the effect of ensuring stability and convenient and fast operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

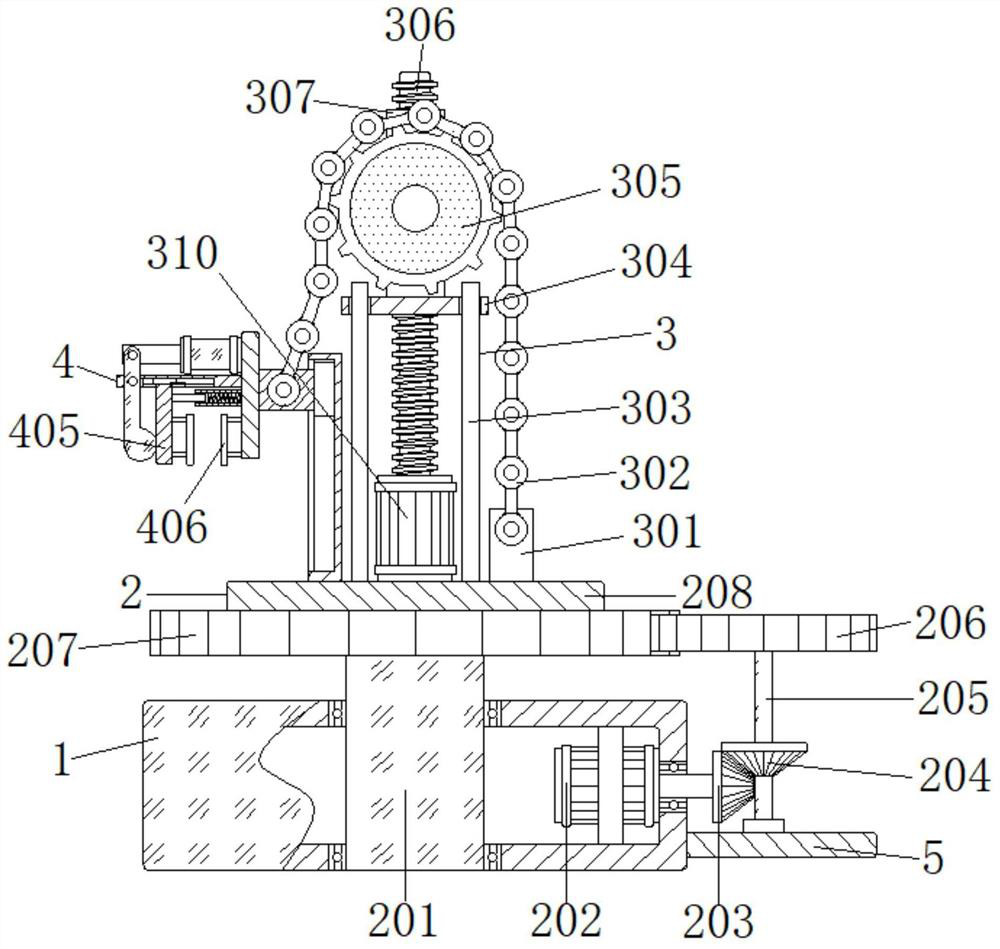

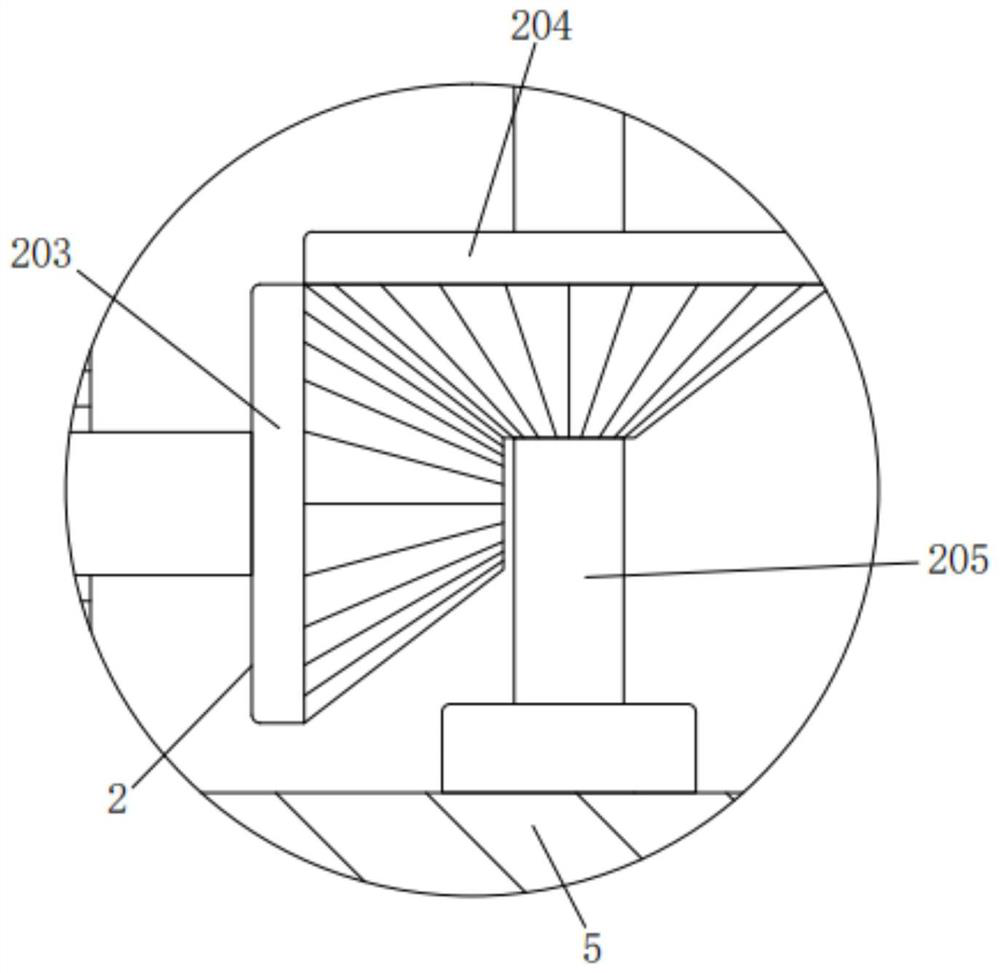

[0031] An intelligent handling industrial robot with stable clamping includes a box body 1, a horizontal plate 5 is fixedly connected to the lower right side of the box body 1, and a rotating device 2 is arranged above the horizontal plate 5. The rotating device 2 includes a cylinder 201, a first Motor 202, first gear 203, second gear 204, round rod 205, third gear 206, fourth gear 207 and circular plate 208, the upper and lower sides of the outer wall of cylinder 201 are connected with the inner wall of the upper and lower ends of the box body 1 through bearings Rotationally connected, the bottom of the cylinder 201 is fixedly connected with the fourth gear 207, the transmission ratio of the third gear 206 and the fourth gear 207 is 2:1, this design can make the device more stable during the handling process, the fourth gear 207 The top is fixed with a circular plate 208, the right end of the fourth gear 207 is meshed with a third gear 206, the bottom of the third gear 206 is fix

Embodiment 2

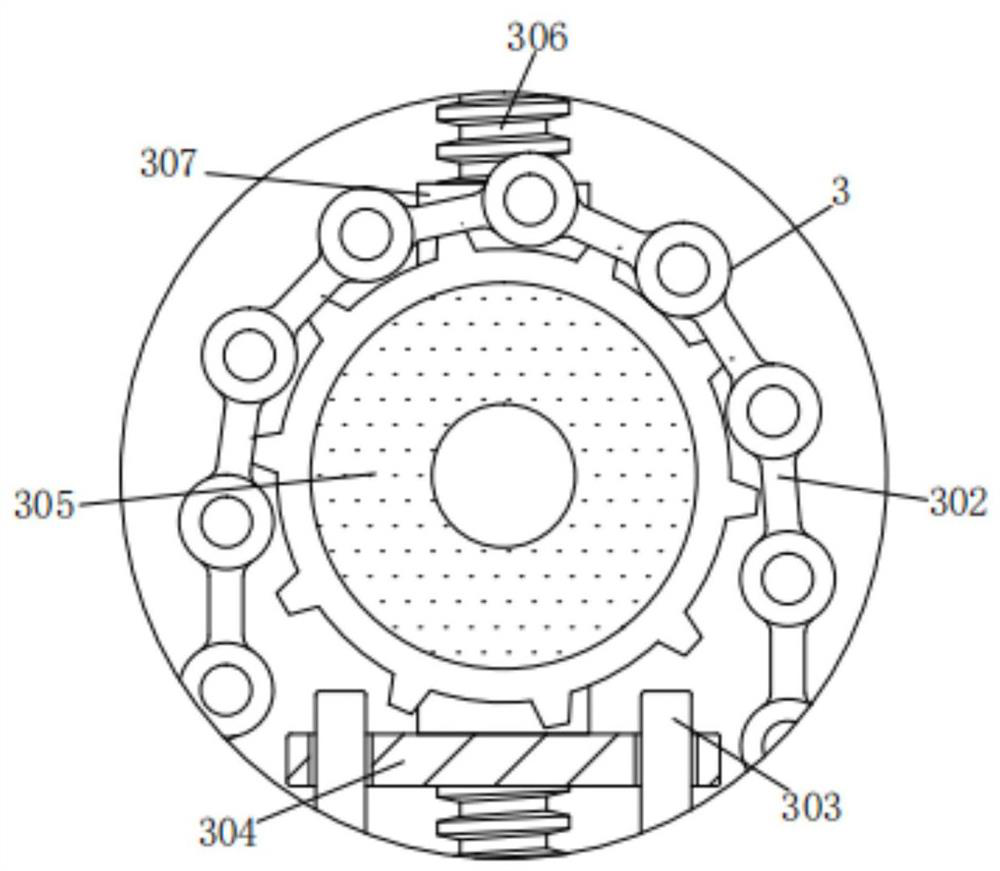

[0033] As an option, see figure 1 , 3And 4, the clamping stable intelligent handling industrial robot, the top of the circular plate 208 is provided with a lifting device 3, the lifting device 3 includes a block 301, a chain 302, a long rod 303, a short plate 304, a fifth gear 305, a threaded rod 306, Long block 307, slide block 308, first groove plate 309 and second motor 310, the bottom of square 301 is fixedly connected with the top right side of circular plate 208, and circular plate 208 plays a supporting role to block 301, and the front end face of square 301 The top is fixedly connected with a chain 302, and the inner side of the chain 302 is meshed with a fifth gear 305. The rear end of the fifth gear 305 is rotatably connected with the front end of the long block 307 through a pin, and the pin makes the fifth gear 305 when stressed. It can rotate at the front end of the long block 307, the long rod short plate 304 is fixedly connected to the front end of the long block

Embodiment 3

[0036] As an option, see figure 1 , 5 And 6,7, clamping stable intelligent handling industrial robot, the left side of slide block 308 is provided with clamping device 4, and clamping device 4 comprises cylinder 401, riser 402, round tube 403, spring 404, square plate 405, Splint 406, short bar 407, curved plate 408, second groove plate 409 and short block 410, the upper right side of vertical plate 402 is fixedly connected with the left end of slider 308, and the upper left side of vertical plate 402 is fixedly connected with cylinder 401, The model of the cylinder 401 is SC80, the left side of the front end surface of the telescopic rod of the cylinder 401 is rotatably connected with the top of the front end surface of the curved plate 408 through the pin shaft, and the top of the rear end surface of the curved plate 408 is connected with the front end surface of the second groove plate 409 through the pin shaft. The left side is fixedly connected, and the pin shaft can rotate

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap