Multi-stage axial-flow compressor of gas turbine

A gas turbine, axial flow technology, applied in axial flow pumps, machines/engines, liquid fuel engines, etc., can solve the problems of device surge, short engine length, insufficient handling of inflowing gas volume, etc., and solve the problem of being vulnerable to damage , Enhance the effect of separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0023]The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, rather than all the embodiments.

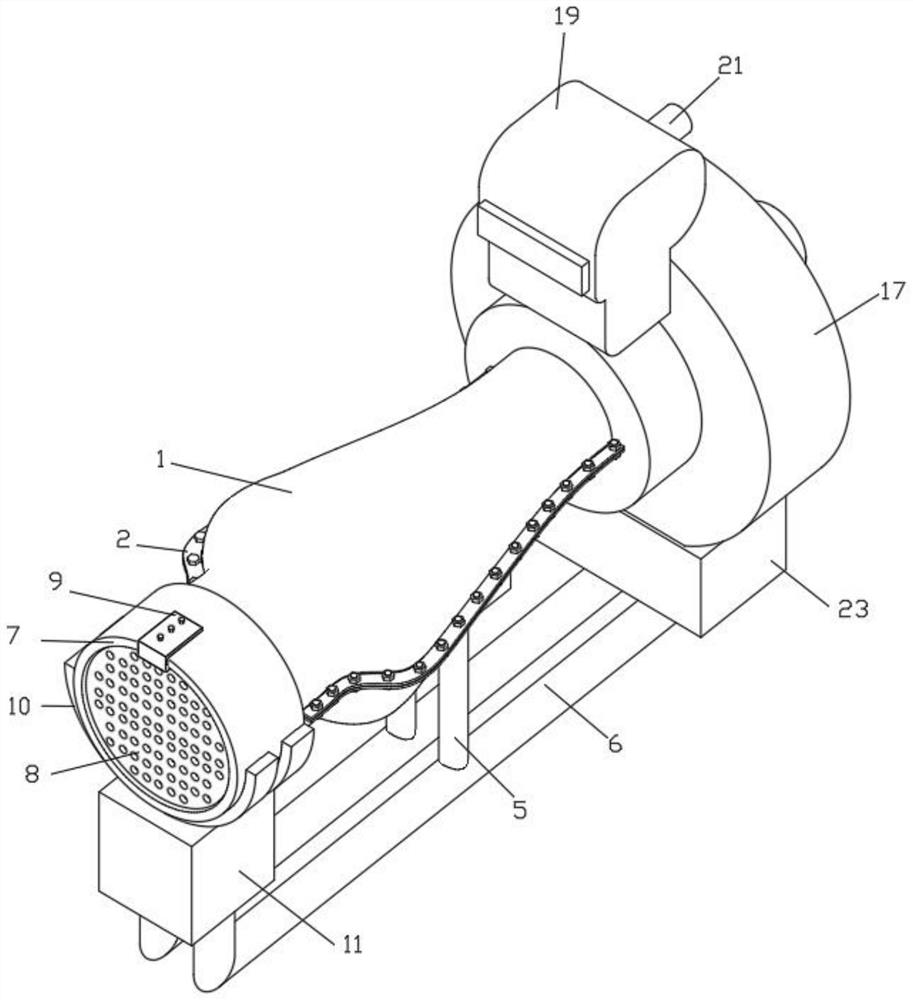

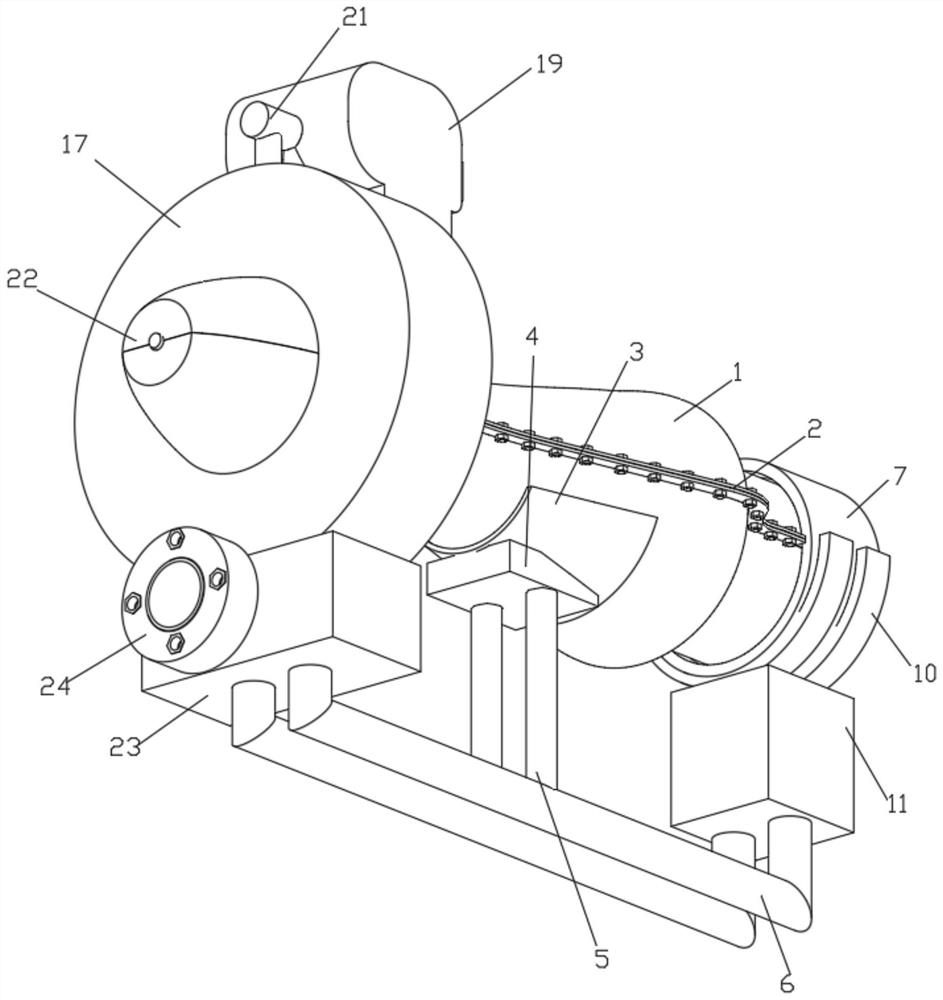

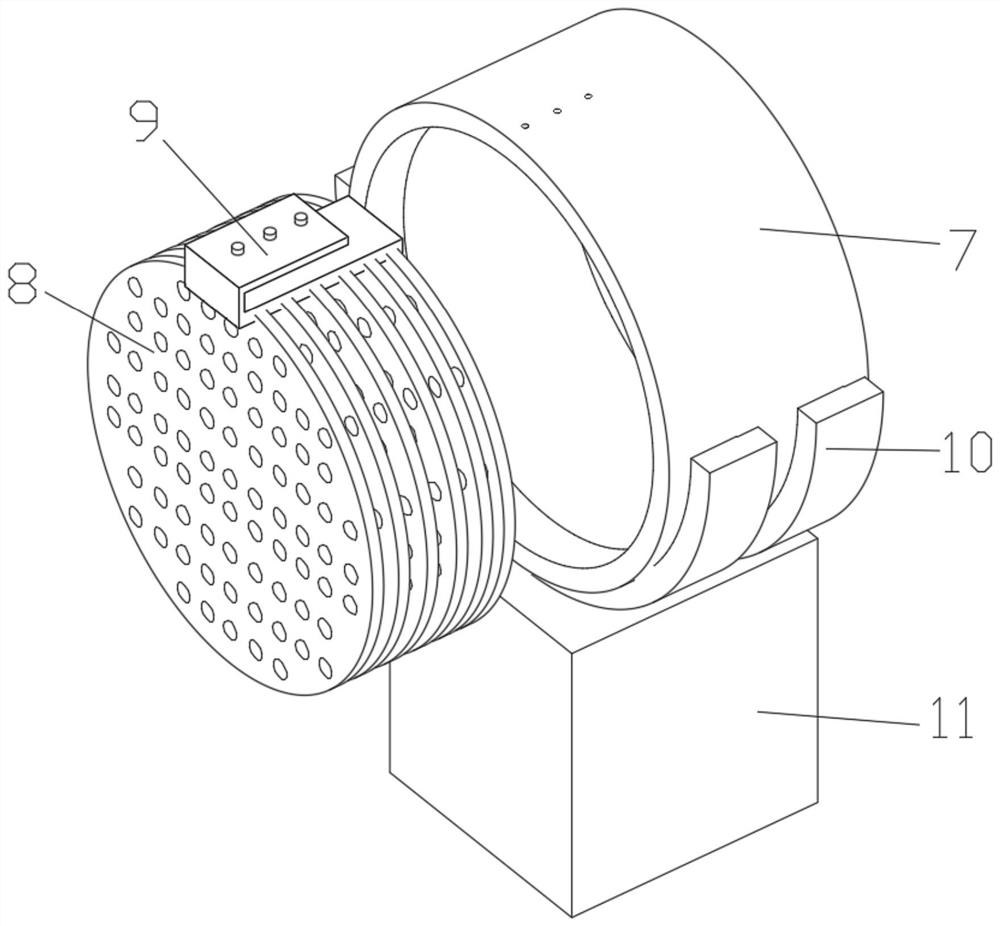

[0024]SeeFigure 1 to Figure 5, The present invention provides a technical solution: a multi-stage axial compressor for a gas turbine, comprising a casing 1, symmetrically distributed positioning pieces 2 are fixedly connected to both sides of the outer casing 1, and the overall shape of the casing 1 is a curved arc The outside of the positioning piece 2 is provided with evenly distributed and threaded holes. The threaded holes on the outside of the positioning piece 2 are movably connected with evenly distributed fixing nuts. The shape of the positioning piece 2 is adapted to the curved surfaces on both sides of the outer shell 1. , By fixing and con

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap