Intelligent welding equipment for U-shaped tube of radiator

A welding equipment and U-shaped pipe technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of easy accident, easy to cause danger, no automatic cleaning, etc., to prevent fire and welding effect. Good, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

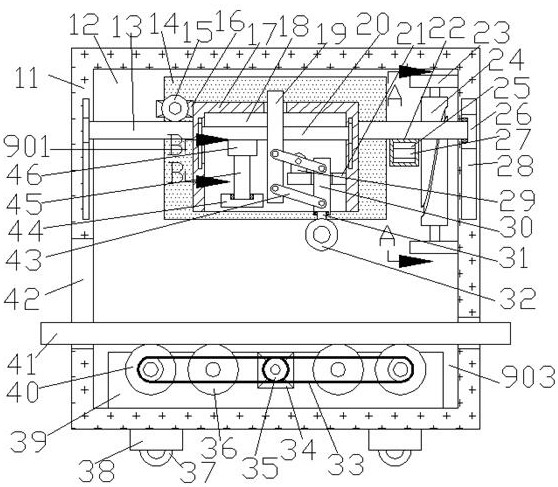

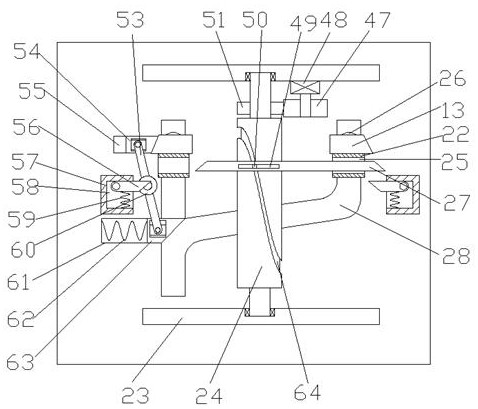

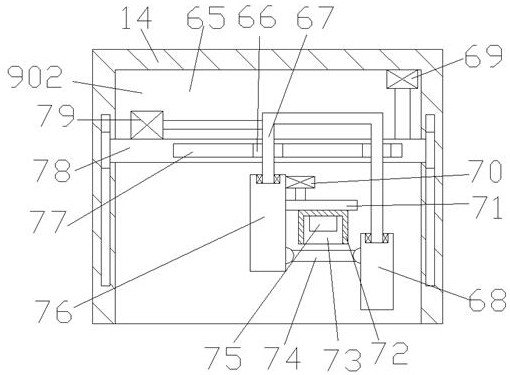

[0016] Combine below Figure 1-4 The present invention is described in detail, wherein, for the convenience of description, the orientations mentioned below are defined as follows: figure 1 The up, down, left, right, front and back directions of the projection relationship itself are consistent.

[0017] A radiator U-shaped tube intelligent welding equipment according to the present invention includes a box body 11, a cavity 12 is arranged in the box body 11, and two vertically symmetrical fixing plates are fixed on the inner wall of the right side of the cavity 12 23. A drum 24 is rotatably connected between the fixed plates 23, and the drum 24 is provided with a chute 64. The upper side of the drum 24 is fixed with a pinion gear 51, and the front side of the pinion gear 51 is meshed with a The main gear 47, the upper side of the main gear 47 is rotatably connected with a motor 48 fixed to the fixed plate 23 on the upper side. With regard to the front and rear symmetrical slid

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap