Bridge rainwater pipe construction vehicle

A technology for rainwater pipes and construction vehicles, applied in bridges, bridge parts, bridge construction and other directions, can solve the problems of high construction risk factor, inconvenient construction, and high difficulty for construction personnel to work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Some simplifications or omissions may be made in this section, as well as in the abstract and titles of this application, to avoid obscuring the purpose of this section, the abstract and titles, and such simplifications or omissions should not be used to limit the scope of the invention.

[0024] In order to make the above objects, features and advantages of the present invention more comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings.

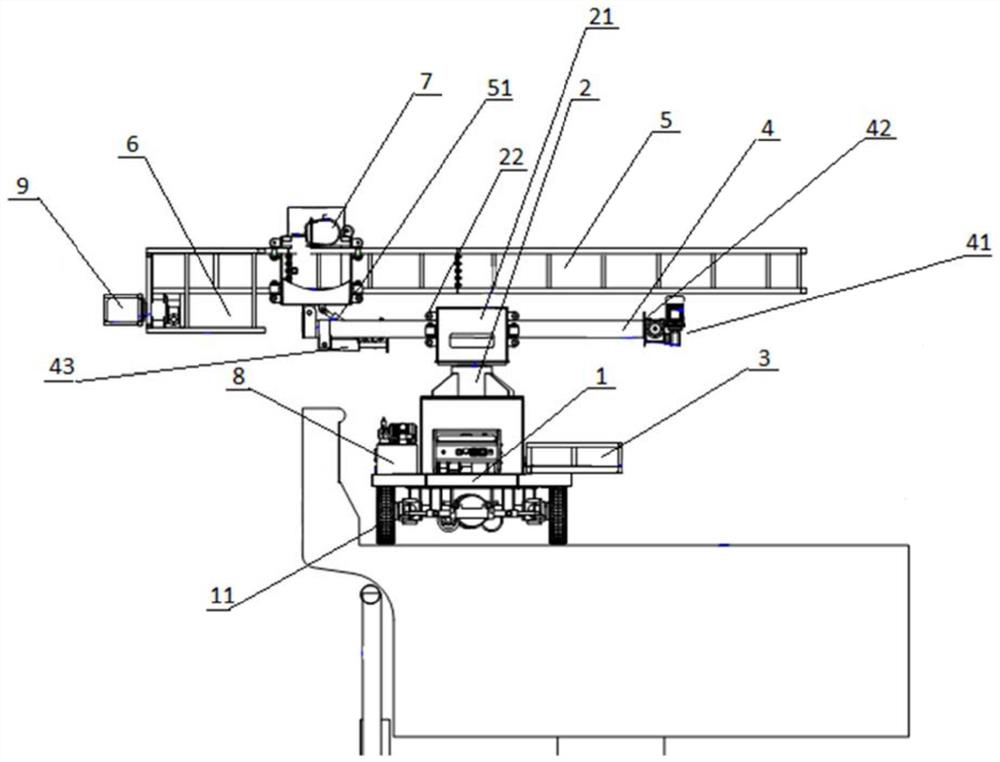

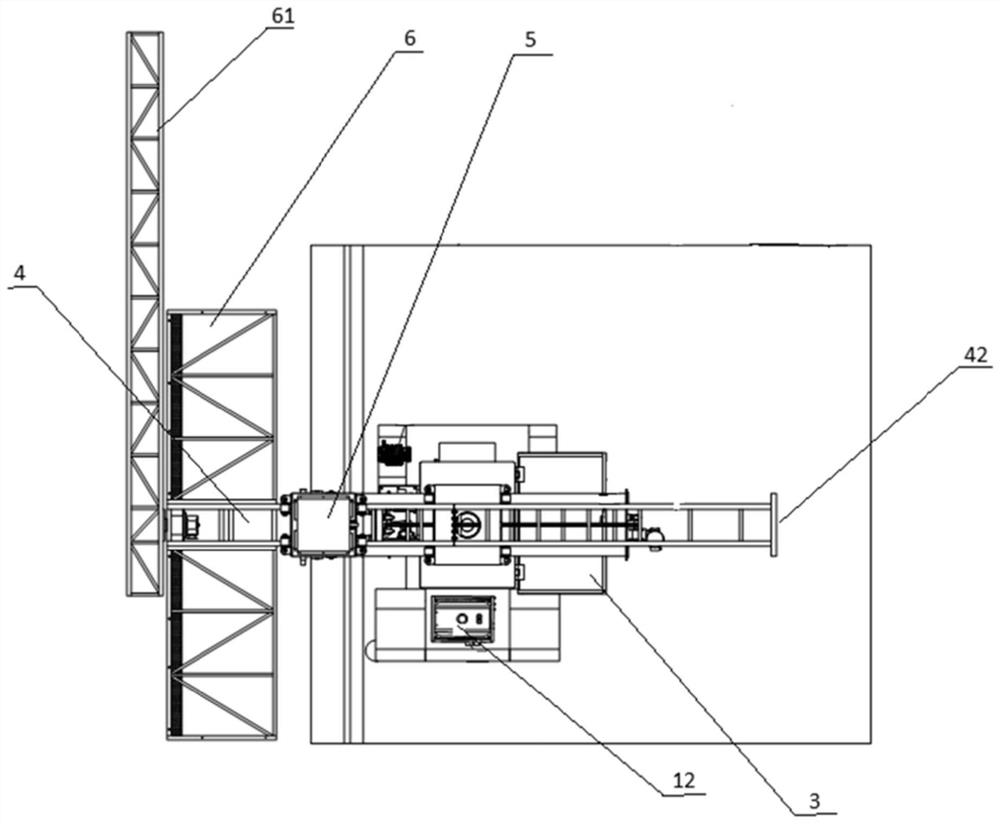

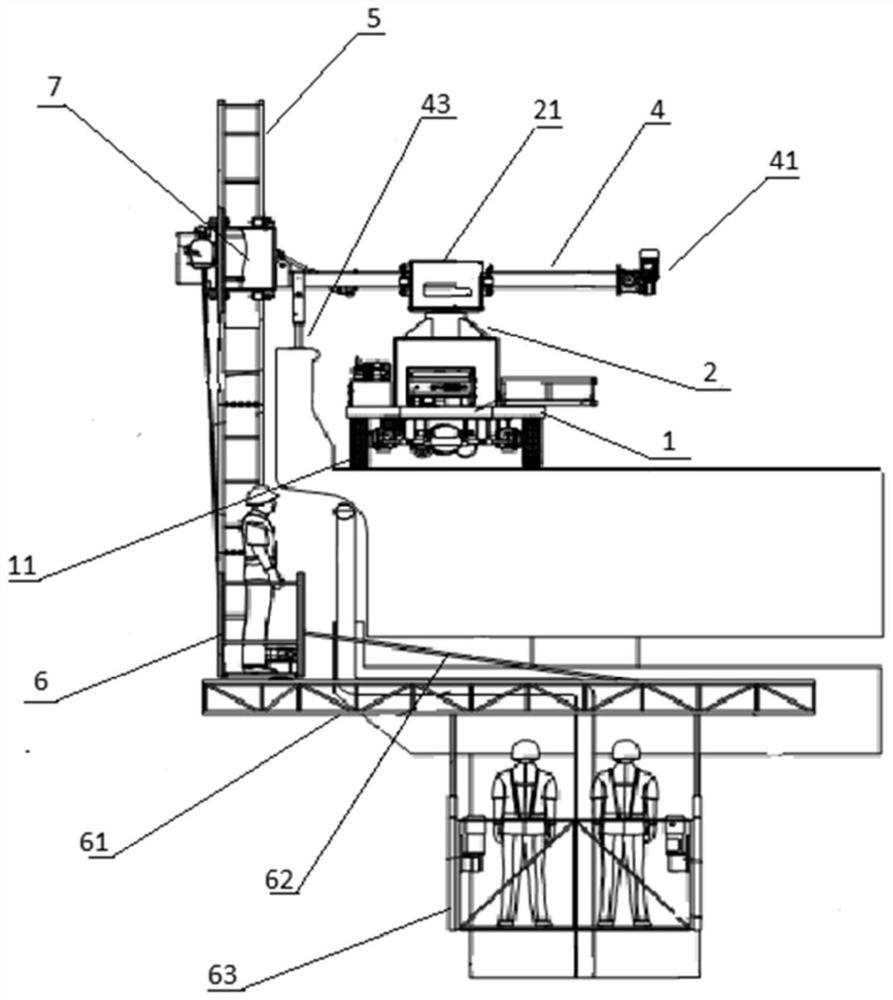

[0025] like Figures 1 to 4 The shown bridge rainwater pipe construction vehicle includes a four-wheel drive trolley, on which a main frame 1 is installed, and a rotating mechanism 2 is installed above the center of the main frame 1, and a gear is arranged under the rotating mechanism 2, and is installed on the main frame 1 The driving motor on the top drives it to rotate, and the rotating mechanism 2 can rotate 360° in the horizontal direction.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap